This category contains lab protocols for the Michigan-Tech Open Sustainability Technology (MOST) Research Group.

MOST method template[edit | edit source]

- List the title of your protocol then:MOST (not MOST first- so things are easy to find in this category) - First word is capitalized but all others are lower cased.

Useful software[edit | edit source]

- MTU MOST Gitlab group and Gitlab Methods

- MTU MOST Github account, MOST SCAD libararies

- Open Science Framework - citable repository MOST repository (Figshare - another possible useful citable repository for data)

- AutoHotkey - a free, open-source macro-creation and automation software for Windows that allows users to automate repetitive tasks. It is driven by a scripting language that was initially aimed at providing keyboard shortcuts, otherwise known as hotkeys, that over time evolved into a full-fledged scripting language (also free but closed source AutoIt (for Windows)

- Veusz- scientific plotting and graphing package

- Dia - diagram editor

- Taverna - for workflows

- Open source engineering software

- Edrawings viewer

- Netfabb STL checker/fixer

- gcode viewer

- Mozilla's Science tools

- How to record screencasts with recordMyDesktop

- Engauge Digitizer

- QR Code generator

- Getting software from MTU http://support.it.mtu.edu/Software-Support/IT-Funded-Software-Requests-Available-Fall-2016-/84033968/What-is-the-Process-for-Requesting-IT-Funded-Software.htm

- Python https://www.anaconda.com/products/individual

- https://thistothat.com/

MOST Research Facilities[edit | edit source]

Space[edit | edit source]

The Pearce group has been allotted two rooms of research space on the 4th and 5th floors of the M&M Building at Michigan Technological University. The space consists of 2 clean hoods, 2 standard fume hoods, and bench top workspace for more than a dozen specialized pieces of equipment and work areas. In addition all metal 3-D printing occurs in 3 bays of fume hood on the 3rd floor lab.

Computers[edit | edit source]

The Pearce group laboratories are equipped with >10 Linux-based computers and >10 PC-compatible computers that run up-to-date software for word processing, graphics, engineering design and data manipulation. All computers have Internet connections though hi-speed Ethernet ports or wireless and connect to a laser printer and copier in the offices. In addition, most 3D printers in the MOST lab have a stand-alone computer/microcomputer of some kind.

Offices[edit | edit source]

All graduate students have shared office space as part of the MSE and ECE programs. Each student has a desk, which are equipped with Ethernet ports and each office has file cabinets for storage, as well as access to shared printers. The PI has an office down the hall from the main laboratory on the 5th floor with sufficient space for scientific discussions with 3 students and has access to numerous conference rooms within the building for group meetings.

Rapid Prototyping Facilities[edit | edit source]

Mechanical[edit | edit source]

The Pearce laboratory is fully stocked with standard electrical and mechanical equipment for open-source rapid prototyping using 3-D printing including approximately a dozen open source RepRap printers of MTU design (e.g. MOST deltas or 4 heavily modified Mendell/Prusa-style RepRap printers), 2 Gigabots (one highly modified), a Gigabot X, CNC R printers, and over 30 Lulzbot Taz, and miniTaz printers.In addition we have 5 OS metal 3-D printers that use GMAW technology as well as sever syringe printers, slot die, and wax printers.

In addition, MTU developed the first RecycleBots and has approximately six different versions of these waste plastic extruders and some commercial variants for testing. We also have an open source chopper for making composite filament.

- MTU also has a Fanuc robot arm converted to WAAM system.

- Nanoscribe

Electronics[edit | edit source]

Dr. Pearce's group has the ability to do in-lab PCB design and either milling or printing on augmented 3-D printers using open source tool chains, although for bigger jobs and or any need for the microfab we use the electronic design and test facilities in the ECE department. The Michigan Tech Department of Electrical and Computer Engineering has extensive design and electronic test resources available. These include:

- CNC based printed circuit board prototype production capabilities with 5 mil feature resolution.

- Extensive resources for electronic test equipment including numerous digital volt-ohmmeters, Keithley and Agilent DMM and electrometers, current model Agilent 40MHz signal and word generators, Agilent/hp and Tektronix storage oscilloscopes ranging from 60MHz to 8GSa/s and some including digital logic analysis capabilities up to 20MHz. Numerous regulated power supplies, spectrum analyzers, network analyzers, RF test and analysis capabilities to 12GHz for multiple polarizations, two anechoic chambers. Dr. Pearce's group has the ability to do in-lab PCB design and either milling or printing on augmented 3-D printers using open source tool chains, although for bigger jobs and or any need for the microfab we use the electronic design and test facilities in the ECE department.

The Michigan Tech Department of Electrical and Computer Engineering has extensive design and electronic test resources available. These include:

- CNC based printed circuit board prototype production capabilities with 5 mil feature resolution.

- Extensive resources for electronic test equipment including numerous digital volt-ohmmeters, Keithley and Agilent DMM and electrometers, current model Agilent 40MHz signal and word generators, Agilent/hp and Tektronix storage oscilloscopes ranging from 60MHz to 8GSa/s and some including digital logic analysis capabilities up to 20MHz. Numerous regulated power supplies, spectrum analyzers, network analyzers, RF test and analysis capabilities to 12GHz for multiple polarizations, two anechoic chambers.

- Design tools including the full Cadence EDA software suit, the full Mentor Graphics EDA software suite, Eagle PCB layout, several versions of SPICE simulation capabilities, Coventorware MEMS design software, ANSYS FEA design software, Comsol Multiphysics, and the Ansoft e-mag software suite.

- Wafer probing capabilities in the MTU Microfabrication Facility include two Micromanipulator wafer probers capable of 100mm and 200mm substrate probing down to 2 micron accuracy. Instrumentation includes a Keithley 4200-SCS semiconductor parametric analyzer with pulsed IV capabilities, a hp/Agilent 4145A semiconductor parametric analyzer, a 4284A precision LCR meter, a 4180A picoammeter, two Keithley model 220 precision current sources and two model 2400 Sourcemeters, a Keithley model 196 system DMM and two hp/Agilent 3478A multi DMMs. Many other instruments are available through the ECE department common laboratory resources for use as appropriate.

- Wire bonding capabilities in the MTU Microfabrication Facility includes a K&S Au wedge-wedge wire bonder operating at temperatures up to 400°C.Dr. Pearce's group has the ability to do in-lab PCB design and either milling or printing on augmented 3-D printers using open source tool chains, although for bigger jobs and or any need for the microfab we use the electronic design and test facilities in the ECE department.

Optical Microscopy Facilities[edit | edit source]

Complete facilities are available for optical microscopy. The following microscopes are available:

- Olympus BX-60 petrographic microscope equipped for plane polarized, cross polarized, and UV illumination. System includes an Optronics 3 chip color CCD camera and on-chip frame averaging capabilities. Microscope is interfaced to an Apple Power PC 7300/200 with a Scion frame grabber capable of 30 frames per second acquisition and NIH Image 1.62 image analysis software.

- Olympus SZH-10 stereo zoom optical microscope equipped for conventional and UV illumination. System includes an Optronics 3 chip color CCD camera and on-chip frame averaging capabilities. Microscope is interfaced to an Apple Power PC 8500/300 with a Scion frame grabber capable of 30 frames per second acquisition and NIH Image 1.62 image analysis software. A Prior 2-axis automated stage with four inches of stage travel and software for performing ASTM C 457 air void system analysis.

- Olympus PME-3 metallographic optical microscopes.

- Olympus PMG-3 metallographic optical microscopes.

- Olympus SZ60 stereo microscopes.

- Two Olympus PMG-3 optical microscopes are equipped with a Hitachi VK-C360 Color Video Camera for video image capture.

- One Olympus PME-3 optical microscope is interfaced to a LECO 2001 automated image analysis system.

- Zeiss Axiomat.

- Multiple dark room facilities for film development and reproduction are available.

Light[edit | edit source]

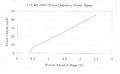

Other Solar and PV testing resources

- An AM1.5 1 sun solar simulator

- PV Measurements QE system

- Custom mapping 4 point probe station

- Custom I-V system

- Calibrated light source -- Ocean Optics DH-2000-CAL. It is a UV-VIS-NIR light source with two lamps, a deuterium and a halogen lamp..

- Several Ocean Optics portable spectrometers covering UV to NIR -- all of which are usb digital with the full software licenses.

- Ocean Optics USB2000 Spectrometer w/ Software (175-502nm 25uM slit)

- Ocean Optics USB2000+ spectrometer with a 200nm to 1100nm range.

- NIRQuest 512-2.5 -- 900 – 2500 nm.

- A collection of open-source spectrometers from Public Lab (400-700nm) and Spectruino (380-750nm).

Outdoors

- KRC outdoor PV testing facility including KRC weather station - includes live, webcam and full archival weather data, for solar flux - Eppley PSPs not heated or aspirated. We also have a number of custom outdoor PV test rigs of various configurations including heated pyranometers at tilt.

Microstructural Characterization Sample Preparation Facilities[edit | edit source]

All the necessary facilities are available for the preparation of specimens for characterization and mechanical test analysis including:

- Lapmaster precision lapping machine for final polishing of large slabs.

- Dansk-Beton Technic precision thin-section grinder for preparing thin sections of uniform thickness.

- Buehler Vibromet 1 vibratory polisher.

- Buehler Ecomet 4 variable speed grinder/polisher with Automet 2 power head.

- Diamond Pacific 24 inch lapping wheel.

- Buehler Isomet 1000 precision saw.

- Ingram Laboratories Model 103 thin section cut-off saw.

- Ingram Laboratories Model 204 thin section grinder.

- Logitech CS 10 thin section cut-off saw.

- Logitech IU 30 vacuum impregnation chamber with articulated epoxy injector.

- LECO GR-20 grinding wheels.

- LECO AP-50 Automatic Polishing Machine.

- LECO AP-300 Automatic Polishing Machine.

- Multiple 36-inch diameter diamond bladed section saws for operation with either water or oil cooling medium.

- Conductive coating facilities for electron microscope sample preparation.

- Tyler and Gilson Sieves.

- Precision temperature controlled 30 cubic foot Despatch LEB Series drying oven.

- Jones Riffles.

- Laboratory scale crushers and grinders including gyratory, jaw, cone, roller, and short head crushers plus ball, roll, and gyratory grinders.

Mechanical Testing[edit | edit source]

In addition, we have mechanical testing facilities for all standard tests for FFF 3-D printed components following: B. M. Tymrak, M. Kreiger, and J. M Pearce, "Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions", Materials and Design 58, pp. 242-246 (2014). doi: 10.1016/j.matdes.2014.02.038

Chemistry Testing[edit | edit source]

In addition to the standard laboratory equipment for organic and polymer laboratories, computing facilities, and image analysis software, MTU has the following major equipment:

- Bruker Microflex LRF MALDI-TOF

- Thermo-Finnigan LCQ Advantage Ion-Trap LC-MS

- Shimadzu GCMS-QP5050 GC-MS

- Varian 400 MH NMR (H, C13, F19, P31)

- Perkin Elmer, Spectrum One FTIR

- Perkin Elmer Lambda 35 UV-Vis

X-ray Diffraction and X-ray Spectrometry Facilities[edit | edit source]

A fully equipped X-ray diffraction (XRD) facility is available for powder diffraction, phase identification, crystal orientation, texture, high temperature diffraction, quantitative analysis, structure determination, and profile fitting. Also X-ray fluorescence spectrometry (XRF) facilities are available for bulk chemical analysis. Equipment includes:

- Scintag XDS-2000 automated diffractometer featuring a q/q vertical goniometer.

- Scintag XDS-2000 automated diffractometer featuring a 3-axis Pole figure, Texture, and Stress (PTS) horizontal goniometer.

- Siemens D-500 automated diffractometer featuring a q/2q vertical goniometer.

- Siemens Type-F manual/automated diffractometer with an Anton Paar high temperature vacuum sample chamber on a horizontal goniometer.

- Picker Nuclear manual/automated diffractometer.

- Philips Electronic Instruments X-ray generator and 4 track tube tower featuring a Polaroid back reflection Laue camera. Various other camera attachments are available.

- Rigaku small angle scattering goniometer.

- Picker Nuclear manual diffractometer featuring a horizontal goniometer.

- General Electric XRD-5 X-ray generator with two 3 track tube towers. Camera attachments available are Polaroid back reflection Laue, Cut film (back reflection and transmission) Laue cameras, Debye-Scherrer powder diffraction cameras, and various specialty cameras.

- ARL Fisons 9400 X-ray wavelength dispersive fluorescence spectrometer for bulk chemical analysis of all elements from boron to uranium.

Materials Characterization Laboratory[edit | edit source]

The Applied Chemical and Morphological Analyses Laboratory (ACMAL) is a Michigan Technological University facility that houses an extensive array of electron microanalytical and x-ray instruments. The Center is managed by the Department of Materials Science and Engineering and located on the 6th floor of the Minerals and Materials Engineering Building. Electron beam instrumentation includes three scanning electron microscopes (SEM), two transmission electron microscopes (TEM) and a dedicated electron microprobe analyzer (EMPA). X-ray equipment includes a sequential x-ray fluorscence spectrometer and five x-ray diffractometers.

- Hitachi S-4700 FE-SEM with 1.2nm resolution and energy dispersive spectrometry.

- Hitachi FB-2000A Focused ion beam system with 7nm spot size.

- JEOL JSM-6400 SEM with energy dispersive spectrometry. This system is equipped with backscattered electron detectors, Oxford eXL EDS systems, and Oxford LEMAS Stage Automation systems. The JEOL 6400 SEM is also equipped with an Oxford EBSP analyzer system that is used to determine the crystallographic orientation of phases within a specimen using electron backscattered Kikuchi patterns. It is equipped with Oxford Featurescan quantitative image analysis systems including Phase Distribution Analysis (PDA).

- A JEOL 4000 FX and two JEOL 100 CX scanning transmission electron microscopes (STEM) equipped with Oxford eXL EDS systems and Featurescan quantitative image analysis systems.

- Perkin-Elmer 660 scanning Auger microscope (SAM).

- Physical Electronics scanning Auger microscope.

- Instruments for determining carbon and sulfur levels.

- Atomic force microscopy (AFM) and scanning tunneling microscopy (STM).

- A new Philips XL40 environmental scanning electron microscope (ESEM). The Philips ESEM is equipped with an EDAX energy dispersive x-ray analyzer system (EDS) for determining phase chemistry and a TSL orientation image mapping (OIM) system for determination of crystallographic orientation of phases using electron backscattered Kikuchi patterns. A Fullam tensile and compression stage is available, as well as a variety of temperature-environmental stages that provide a full range of environmental conditions. It is housed in the Non-Conductive/Volatile Materials Characterization Facility.

- Oxford/Horiba XGT-2000W x-ray analytical microscope with capabilities for performing x-ray microanalysis of specimens at atmospheric pressure, x-ray mapping, and x-ray imaging. This is a newly developed instrument for imaging and analyzing materials using a focused x-ray flux. It has been ordered with delivery expected in the near future, and will be housed in the Non-Conductive/Volatile Materials Characterization Facility.

Facilities at MTU[edit | edit source]

- Michigan Tech Resources- Tech Finder http://finder.mtu.edu/

- Dr. King's group

- 7th floor MISTI procedures

- IEEE lab

- GIS software/data at MTU

- ACMAL - The authors acknowledge the Applied Chemical and Morphological Analysis Laboratory at Michigan Tech for use of the instruments and staff assistance.

MTU MFF internal rates

Tools Rate

Denton e-beam (432 M&M Building)

Fredrick e-beam (432 M&M Building) $48/hr - up from $43/hr

8" sputter (432 M&M Building)

6" sputter (432 M&M Building)

Parylene Coater (432 M&M Building)

TRION (431 M&M Building)

MARCH etcher (431 M&M Building)

CAIBE (431 M&M Building)

Tools Rate

EV620 Mask Aligner (429 M&M Building) $71/hr - no change

Tools Rate

3D profiler (431 M&M Building)

Wire Bonder (424 M&M Building) $21/hr - up from $19.50/hr

JA Woollam Ellipsometer (431 M&M

Building)

Dicing Saw (429 M&M Building) -

Nikon Microscope (429 M&M Building)

Chemical Processing (429 and 420 M&M Building)

Polymer Spinner (429 M&M Building)

RTP (428 M&M Building) -

2" Furnace (428 M&M Building)

Mellon Oxidation Furnace (428 M&M Building) -

Mellon Diffusion Furnace (428 M&M Building)

Outreach after[edit | edit source]

- Making good sci videos

- Best times to post on social media

- Synfig OS 2-D animation

- open clip art

- Free Music

OS Videos[edit | edit source]

- Pixabay Videos - Copyright-free HD videos and footage released under Creative Commons CC0.

- Archive.org open-source movies - Movies under several licenses. Some licenses are accepted in the commons.

- Archive.org movies - Presentation of several collections of videos, some with free licenses.

- Prelinger Archives - over 2,000 public domain videos of "historic significance"

- Flickr Creative Commons videos - all assortments of videos.

- Flickr The Commons - a variety of videos licensed freely by many institutions

- European Southern Observatory videos - space and astronomy videos licensed under Creative Commons Attribution[1]

- Open Images project, an initiative from the Netherlands Institute for Sound and Vision. Many of the videos contain Dutch audio., so it's advised to remove the audio when uploading to Wikipedias other than the Dutch Wikipedia.

- NASA videos

- White House (Youtube channel)

- Kremlin.ru (Official Website of President of the Russian Federation) - All materials (fotos, texts, videos, audios, etc.) licensed under Creative Commons Attribution 3.0 Unported (CC-BY 3.0 Unported),

- Beachfront B-Roll - Constantly updated personal blog offering, for free, royalty free HD stock video, High Definition and HDR time lapse clips and HD animated looping backgrounds for any personal, corporate and commercial use. Downloads are a simple "Right Click Save" and the files are hosted by Archive.org.

- Free Stock Footage Archive Free glitch footage licensed under Creative Commons Attribution 3.0 Unported (CC-BY 3.0 Unported)

- Videvo Stock Footage Royalty-Free Stock Video Footage CC licensed (BY-3.0) or licensed by the company for easy use in non-commercial and commercial projects.

- Mazwai Stock Video Royalty-Free Stock Video Footage CC licensed (BY-3.0). Free to use, for commercial and non-commercial works, but you must credit the author of the clip.

Research Data Repository Approaches[edit | edit source]

- MTU citation search

- MOST Github stuff

- Pearce Academia account

- Pearce/MOST Thingiverse account

- Pearce Research gate

- MSE SOPs http://sop.mse.mtu.edu/index.php?title=Category:SOP

- Figshare working with Github and Mozilla to enable 'Code as a Research Output' - See more at: http://figshare.com/blog/Working_with_Github_and_Mozilla_to_enable_Code_as_a_Research_Output_/117#sthash.JR5cCWxA.dpuf

- F1000Research and the Force11 Data Citation Principles - See more at: http://blog.f1000research.com/2014/03/10/f1000research-and-the-force11-data-citation-principles/#sthash.jWLW365U.dpuf

Open Educational Resources[edit | edit source]

Subcategories

This category has the following 6 subcategories, out of 6 total.

M

- MOST backpack delta (5)

- MOST Delta Build (29)

- MOST RepRap build (21)

- MOST RepRap methods (25)

O

- Open source optics (69)

Pages in category "MOST methods"

The following 200 pages are in this category, out of 346 total.

(previous page) (next page)3

- 3-D printed weld bead geometry characterization

- 3-D printed weld bead geometry characterization/id

- 3-D printer tent

- 3D Metal Printing Slicer Plugin

- 3D Metal Printing Slicer Plugin/cs

- 3D Metal Printing Slicer Plugin/ru

- 3D Printed Micromanipulator

- 3D printer bed adhesion:MOST

- 3D Printing Basics:MOST

- 3D Printing Failure Database

- 3D Printing Failure Database/zh

A

- ABS recycling for 3-D printer filament

- Aluminum substrate cleaning for 3-D printing:MOST

- Aluminum substrate cleaning for 3-D printing:MOST/zh

- Angle of Repose Analysis

- Arduino installation

- Arduino use: MOST

- Arduino use: MOST/es

- Artificial lung method MOST

- Assembling Delta Tie Rods:MOST

- Assembling Delta:MOST

- Assembling PlanetaryGearbox:MOST

- Atomic Force Microscopy(AFM) Protocol : MOST

- Atomic layer deposition:MOST

- Auto-Clearance Adjustable Triple Hotend Effector

B

C

- Calibrated light source:MOST

- Characterizing GaN:MOST

- Chemtool(How to draw chemistry):MOST

- Chenlong Nanobeads Project

- CNC Router Parts metal 3D printer

- CNC Router Parts-based metal printers SOP

- Contact angle measurement on coated glass

- Contact angle with cell phone

- Contact angle with cell phone/ru

- Converting 2D images to 3D for printing using open source software

- Converting 2D images to 3D for printing using open source software/da

- Converting 2D images to 3D for printing using open source software/pt

- Converting 2D images to 3D for printing using open source software/ro

- Converting 2D images to 3D for printing using open source software/zh

- Converting stl files to dualstrusions

- Creating Syringe Printer using a Lulzbot Mini

D

- Delta Build Overview:MOST

- Delta Build Overview:MOST/es

- Delta Build Overview:MOST/fr

- Delta Build Overview:MOST/nl

- Delta Build Overview:MOST/zh

- Delta Build Workshop

- Delta Extruder Drive Assembly:MOST

- Delta Idler End:MOST

- Delta Motor End Assembly:MOST

- Delta Pilot Holes:MOST

- Delta Software:MOST

- Delta Software:MOST/zh

- Delta Vertical Boards:MOST

- Delta Wiring:MOST

- Delta Wiring:MOST/ru

- Differential scanning calorimetry protocol: MOST

- Differential scanning calorimetry protocol: MOST/es

- Digital mass protocol:MOST

- Dip coating:MOST

- Dr. Frost sodis polymer experimental procedure

- Dr. Frost UV spectroscopy unit protocol MOST

- Dr. Hu solar simulator protocol: MOST

- Drill Press (Shop Fox W1848):MOST

E

F

- FEA compression in FreeCAD

- FEA in FreeCAD Tensile bar: ASTM D638-14 Type IV

- Filament print settings: MOST

- Finite element analysis: MOST

- Focussed Ion beam (FIB) protocol: MOST

- Focussed Ion beam (FIB) protocol: MOST/zh

- Four Point Resistivity and Conductivity Type Measurements protocol: MOST

- Four Point Resistivity and Conductivity Type Measurements protocol: MOST/fr

- Four Point Resistivity and Conductivity Type Measurements protocol: MOST/zh

- Franklin

- Franklin Firmware on GigabotHX:MOST

- Franklin/cs

- Franklin/ja

- Franklin/ko

- Franklin/ru

- Franklin/zh

- Franklin:MOST

G

- Generating gcode for MTU CNC 3-D printers

- Gigabot Polymer Printing:MOST

- Gigabot X Usage

- GigabotHX

- Gitlab:MOST

- Gitlab:MOST/zh

- Glass substrate cleaning method: MOST

- Glass substrate cleaning method: MOST/es

- Glass substrate cleaning method: MOST/ja

- Glass substrate cleaning method: MOST/ko

- Glass substrate cleaning method: MOST/mr

- Glass substrate cleaning method: MOST/vi

- Glass substrate cleaning method: MOST/zh

- GNUPlot method: MOST

- Grinding Mill in Forestry Plant:MOST

H

- High-Temperature Syringe Printer:MOST

- High-Temperature Syringe Printer:MOST/zh

- Hot end holder with 3 fans

- How to convert 3D Studio to stl

- How to convert 3D Studio to stl/es

- How to convert 3D Studio to stl/it

- How to convert 3D Studio to stl/ru

- How to convert 3D Studio to stl/tr

- How to design open source electronics

- How to do a third-party preinssurance submission

- How to encrypt Gmail:MOST

- How to get embodied energy from CES database

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi/de

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi/es

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi/hu

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi/ja

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi/ko

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi/tr

- How to install FLIR Lepton Thermal Camera and applications on Raspberry Pi/zh

- How to make a figure to publish

- How to make a figure to publish/zh

- How to test new filament on a Taz

I

- Improving recyclebot concepts

- Improving recyclebot concepts/fr

- Improving recyclebot concepts/ru

- Installing RTM Software on Linux

- Isostatic Pressing Protocol (HIP\CIP):MOST

- Isostatic Pressing Protocol (HIP\CIP):MOST/ko

- Isostatic Pressing Protocol (HIP\CIP):MOST/th

- Isostatic Pressing Protocol (HIP\CIP):MOST/zh

L

- Laser dot welding : MOST

- Laser welding protocol: MOST

- Leaf concentrate

- Leaf concentrate mass experiment

- Life cycle analysis of semiconductor recycling in thin film photovoltaic manufacturing methods

- Life cycle analysis tools

- Life cycle analysis: MOST

- Linear and Bending magnetic actuation test:MOST

- Lulzbot mini user guide:MOST

- Lulzbot TAZ user guide:MOST

- Lulzot Bioprinter

M

- MakerBot Replicator protocol:MOST

- Making pluronic hydrogel

- Making thermocouples protocol: MOST

- MBE protocol:MOST

- Measuring contact angles in the field: Protocol

- Mechanical testing of 3D printed metal parts

- Metal wire embedding in fused filament 3-D printing

- Metal wire embedding in fused filament 3-D printing/it

- Method of producing cellulose insulation

- Method of producing cellulose insulation/fa

- Method of producing cellulose insulation/hr

- Method of producing cellulose insulation/hu

- Method of producing cellulose insulation/ja

- Method of producing cellulose insulation/ko

- Method of producing cellulose insulation/zh

- Methodology for 3D-Printed Part Design

- Methods to Operate Chromation Spectrometer

- Mini-metal 3d printer:MOST

- Mini-metal 3d printer:MOST/ru

- Mixing of glass powder filled polymer composite in furnace

- MOST 3 Axis Stage

- MOST 3-D printer workshop preparation

- MOST Delta Auto Bed Leveling

- MOST Delta end effector for nylon

- MOST Delta end effector for polypropylene

- MOST delta-based metal printers SOP

- MOST HS animation

- MOST Injection Molder

- MOST Lab COVID19 Restart and Medical Production

- MOST Metal Cura

- MOST Metal Cura/ru

- MOST Metal Cura/zh

- Preload:MOST methods

- MOST Mount Bases

- Appropedia:MOST multi file upload

- MOST open-source metal 3-D printer v2

- MOST open-source metal 3-D printer v2 Assembly/zh

- MOST open-source metal 3-D printer v2/fr

- MOST open-source metal 3-D printer v2/ru

- MOST open-source metal 3-D printer v2/zh

- MOST paper writing

- MOST Printer Log

- MOST quad delta RepRap

- MOST Stage v1

- MOST-Delta Customization

- Motor force protocol

Media in category "MOST methods"

The following 154 files are in this category, out of 154 total.

-

3DP Data Sheet.odt ; 9 KB

-

Ev Wavenumber Wavelength.xls ; 19 KB

-

InGaN bandgap calc.ods ; 114 KB

-

LED incan cfl worksheet2.ods ; 32 KB

-

LED-vs-incan in Houghton.ods ; 31 KB

-

MOST HSPrusa alignment 0.jpg 640 × 425; 131 KB

-

MOST HSPrusa alignment 1.jpg 640 × 480; 148 KB

-

MOST HSPrusa alignment 2.jpg 640 × 480; 150 KB

-

MOST HSPrusa alignment 3.jpg 132 × 480; 68 KB

-

MOST HSPrusa alignment 4.jpg 317 × 480; 88 KB

-

MOST HSPrusa alignment 5.jpg 640 × 480; 107 KB

-

MOST HSPrusa complete 0.jpg 640 × 480; 87 KB

-

MOST HSPrusa complete 1.jpg 462 × 480; 86 KB

-

MOST HSPrusa complete 2.jpg 397 × 480; 74 KB

-

MOST HSPrusa complete 3.jpg 404 × 480; 73 KB

-

MOST HSPrusa electronics 0.jpg 312 × 480; 58 KB

-

MOST HSPrusa electronics 1.jpg 499 × 480; 54 KB

-

MOST HSPrusa electronics 2.jpg 640 × 480; 45 KB

-

MOST HSPrusa electronics 3.jpg 640 × 425; 57 KB

-

MOST HSPrusa electronics 4.jpg 640 × 444; 61 KB

-

MOST HSPrusa electronics 5.jpg 593 × 480; 79 KB

-

MOST HSPrusa electronics 6.jpg 596 × 480; 78 KB

-

MOST HSPrusa extruder 0.jpg 640 × 480; 62 KB

-

MOST HSPrusa extruder 1.jpg 640 × 480; 60 KB

-

MOST HSPrusa extruder 10.jpg 326 × 480; 31 KB

-

MOST HSPrusa extruder 11.jpg 440 × 480; 38 KB

-

MOST HSPrusa extruder 12.jpg 407 × 480; 36 KB

-

MOST HSPrusa extruder 13.jpg 640 × 480; 45 KB

-

MOST HSPrusa extruder 14.jpg 640 × 480; 46 KB

-

MOST HSPrusa extruder 15.jpg 489 × 480; 44 KB

-

MOST HSPrusa extruder 16.jpg 640 × 480; 44 KB

-

MOST HSPrusa extruder 17.jpg 640 × 426; 50 KB

-

MOST HSPrusa extruder 18.jpg 640 × 290; 40 KB

-

MOST HSPrusa extruder 19.jpg 464 × 480; 45 KB

-

MOST HSPrusa extruder 2.jpg 360 × 480; 40 KB

-

MOST HSPrusa extruder 21.jpg 640 × 480; 56 KB

-

MOST HSPrusa extruder 22.jpg 640 × 480; 58 KB

-

MOST HSPrusa extruder 23.jpg 640 × 413; 58 KB

-

MOST HSPrusa extruder 24.jpg 640 × 480; 49 KB

-

MOST HSPrusa extruder 25.jpg 549 × 480; 62 KB

-

MOST HSPrusa extruder 26.jpg 640 × 480; 44 KB

-

MOST HSPrusa extruder 27.jpg 640 × 480; 61 KB

-

MOST HSPrusa extruder 28.jpg 640 × 480; 62 KB

-

MOST HSPrusa extruder 29.jpg 640 × 480; 69 KB

-

MOST HSPrusa extruder 3.jpg 360 × 480; 40 KB

-

MOST HSPrusa extruder 30.jpg 640 × 480; 64 KB

-

MOST HSPrusa extruder 32.jpg 640 × 480; 86 KB

-

MOST HSPrusa extruder 4.jpg 515 × 480; 66 KB

-

MOST HSPrusa extruder 5.jpg 572 × 480; 73 KB

-

MOST HSPrusa extruder 6.jpg 360 × 480; 40 KB

-

MOST HSPrusa extruder 7.jpg 360 × 480; 42 KB

-

MOST HSPrusa extruder 8.jpg 360 × 480; 41 KB

-

MOST HSPrusa extruder 9.jpg 311 × 480; 31 KB

-

MOST HSPrusa frame 0.jpg 598 × 640; 422 KB

-

MOST HSPrusa frame 1.jpg 640 × 480; 103 KB

-

MOST HSPrusa frame 10.jpg 640 × 224; 22 KB

-

MOST HSPrusa frame 11.jpg 640 × 289; 45 KB

-

MOST HSPrusa frame 2.jpg 524 × 480; 90 KB

-

MOST HSPrusa frame 3.jpg 640 × 421; 108 KB

-

MOST HSPrusa frame 4.jpg 640 × 273; 54 KB

-

MOST HSPrusa frame 5.jpg 640 × 271; 52 KB

-

MOST HSPrusa frame 6.jpg 640 × 316; 50 KB

-

MOST HSPrusa frame 7.jpg 640 × 199; 34 KB

-

MOST HSPrusa frame 8.jpg 537 × 480; 44 KB

-

MOST HSPrusa frame 9.jpg 640 × 273; 25 KB

-

MOST HSPrusa x-axis 0.jpg 640 × 400; 100 KB

-

MOST HSPrusa x-axis 1.jpg 640 × 480; 139 KB

-

MOST HSPrusa x-axis 10.jpg 498 × 480; 74 KB

-

MOST HSPrusa x-axis 11.jpg 640 × 240; 40 KB

-

MOST HSPrusa x-axis 12.jpg 556 × 480; 79 KB

-

MOST HSPrusa x-axis 13.jpg 640 × 480; 64 KB

-

MOST HSPrusa x-axis 14.jpg 640 × 480; 64 KB

-

MOST HSPrusa x-axis 15.jpg 470 × 480; 53 KB

-

MOST HSPrusa x-axis 16.jpg 442 × 480; 52 KB

-

MOST HSPrusa x-axis 17.jpg 498 × 480; 47 KB

-

MOST HSPrusa x-axis 18.jpg 551 × 480; 52 KB

-

MOST HSPrusa x-axis 19.jpg 376 × 480; 44 KB

-

MOST HSPrusa x-axis 2.jpg 640 × 217; 33 KB

-

MOST HSPrusa x-axis 20.jpg 405 × 480; 54 KB

-

MOST HSPrusa x-axis 21.jpg 363 × 480; 48 KB

-

MOST HSPrusa x-axis 22.jpg 350 × 480; 44 KB

-

MOST HSPrusa x-axis 23.jpg 390 × 480; 44 KB

-

MOST HSPrusa x-axis 24.jpg 437 × 480; 47 KB

-

MOST HSPrusa x-axis 25.jpg 572 × 480; 95 KB

-

MOST HSPrusa x-axis 26.jpg 640 × 480; 80 KB

-

MOST HSPrusa x-axis 27.jpg 640 × 327; 74 KB

-

MOST HSPrusa x-axis 28.jpg 289 × 480; 48 KB

-

MOST HSPrusa x-axis 29.jpg 290 × 480; 45 KB

-

MOST HSPrusa x-axis 3.jpg 640 × 480; 52 KB

-

MOST HSPrusa x-axis 30.jpg 640 × 245; 47 KB

-

MOST HSPrusa x-axis 31.jpg 640 × 474; 98 KB

-

MOST HSPrusa x-axis 32.jpg 640 × 220; 37 KB

-

MOST HSPrusa x-axis 33.jpg 640 × 226; 39 KB

-

MOST HSPrusa x-axis 34.jpg 640 × 445; 289 KB

-

MOST HSPrusa x-axis 4.jpg 640 × 480; 60 KB

-

MOST HSPrusa x-axis 5.jpg 640 × 480; 61 KB

-

MOST HSPrusa x-axis 6.jpg 574 × 480; 64 KB

-

MOST HSPrusa x-axis 7.jpg 613 × 480; 69 KB

-

MOST HSPrusa x-axis 8.jpg 640 × 480; 71 KB

-

MOST HSPrusa x-axis 9.jpg 640 × 478; 67 KB

-

MOST HSPrusa y axis 9a.jpg 519 × 507; 97 KB

-

MOST HSPrusa y-axis 0.jpg 640 × 316; 77 KB

-

MOST HSPrusa y-axis 1.jpg 640 × 385; 81 KB

-

MOST HSPrusa y-axis 10.jpg 640 × 480; 115 KB

-

MOST HSPrusa y-axis 2.jpg 640 × 304; 74 KB

-

MOST HSPrusa y-axis 3.jpg 640 × 173; 61 KB

-

MOST HSPrusa y-axis 4.jpg 640 × 300; 74 KB

-

MOST HSPrusa y-axis 5.jpg 360 × 480; 86 KB

-

MOST HSPrusa y-axis 6.jpg 528 × 480; 123 KB

-

MOST HSPrusa y-axis 7.jpg 438 × 480; 105 KB

-

MOST HSPrusa y-axis 8.jpg 571 × 480; 92 KB

-

MOST HSPrusa y-axis 9.jpg 569 × 480; 98 KB

-

MOST HSPrusa y-carriage 0.jpg 589 × 640; 86 KB

-

MOST HSPrusa y-carriage 1.jpg 287 × 480; 76 KB

-

MOST HSPrusa y-carriage 10.jpg 640 × 208; 38 KB

-

MOST HSPrusa y-carriage 11.jpg 507 × 480; 47 KB

-

MOST HSPrusa y-carriage 12.jpg 564 × 480; 54 KB

-

MOST HSPrusa y-carriage 13.jpg 513 × 480; 40 KB

-

MOST HSPrusa y-carriage 14.jpg 640 × 455; 64 KB

-

MOST HSPrusa y-carriage 15.jpg 467 × 480; 58 KB

-

MOST HSPrusa y-carriage 16.jpg 206 × 480; 24 KB

-

MOST HSPrusa y-carriage 17.jpg 485 × 480; 63 KB

-

MOST HSPrusa y-carriage 18.jpg 562 × 480; 71 KB

-

MOST HSPrusa y-carriage 19.jpg 640 × 419; 73 KB

-

MOST HSPrusa y-carriage 2.jpg 640 × 480; 96 KB

-

MOST HSPrusa y-carriage 20.jpg 640 × 290; 54 KB

-

MOST HSPrusa y-carriage 21.jpg 540 × 480; 57 KB

-

MOST HSPrusa y-carriage 3.jpg 640 × 480; 90 KB

-

MOST HSPrusa y-carriage 4.jpg 640 × 305; 54 KB

-

MOST HSPrusa y-carriage 5.jpg 631 × 480; 83 KB

-

MOST HSPrusa y-carriage 6.jpg 640 × 480; 59 KB

-

MOST HSPrusa y-carriage 7.jpg 640 × 333; 56 KB

-

MOST HSPrusa y-carriage 8.jpg 640 × 350; 72 KB

-

MOST HSPrusa y-carriage 9.jpg 640 × 480; 74 KB

-

MOST HSPrusa z-axis 0.jpg 297 × 480; 76 KB

-

MOST HSPrusa z-axis 1.jpg 58 × 388; 50 KB

-

MOST HSPrusa z-axis 10.jpg 640 × 480; 94 KB

-

MOST HSPrusa z-axis 11.jpg 640 × 480; 98 KB

-

MOST HSPrusa z-axis 12.jpg 640 × 480; 93 KB

-

MOST HSPrusa z-axis 13.jpg 640 × 480; 109 KB

-

MOST HSPrusa z-axis 14.jpg 640 × 480; 110 KB

-

MOST HSPrusa z-axis 15.jpg 640 × 480; 85 KB

-

MOST HSPrusa z-axis 2.jpg 452 × 480; 91 KB

-

MOST HSPrusa z-axis 3.jpg 640 × 401; 110 KB

-

MOST HSPrusa z-axis 4.jpg 640 × 309; 89 KB

-

MOST HSPrusa z-axis 5.jpg 343 × 480; 96 KB

-

MOST HSPrusa z-axis 6.jpg 424 × 480; 115 KB

-

MOST HSPrusa z-axis 7.jpg 390 × 480; 105 KB

-

MOST HSPrusa z-axis 8.jpg 484 × 480; 126 KB

-

MOST HSPrusa z-axis 9.jpg 640 × 374; 94 KB

-

MOST laserweld TEMPLATE.svg 974 × 1,134; 13 KB

-

Snowpv-imageanal.jpg 1,238 × 929; 160 KB

-

Submitted drawings-shop.pdf 1,650 × 1,275, 5 pages; 76 KB

-

ZIC 002.jpg 1,632 × 1,008; 70 KB