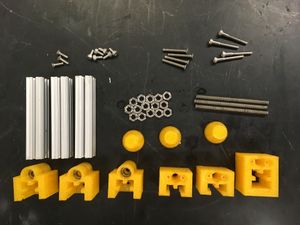

Picture of the parts required to assemble the micromanipulator.

Bill of Materials[edit | edit source]

- 3 pieces of OpenBeam, 75mm long.

- 3 pieces M5 threaded rod, 65mm long.

- 3 M3 x 10mm flat head socket screws.

- 6 M3 x 6mm socket head cap screws.

- 4 M3 x 20mm flat head socket screws.

- 4 M3 x 25mm socket head cap screws.

- 15 M5 hex nuts.

- 6 MR105zz roller bearings (NOT PICTURED).

- 3 printed knobs.

- 3 printed straddle ends.

- 2 printed straddle carriages.

- 1 printed vertical straddle carriage.

Assembly[edit | edit source]

- Jam M5 nuts on one end of each of the threaded rods, chuck into a drill and remove burrs from the threads by rotating in #600 emory cloth or sandpaper.

- Thoroughly clean the threaded rods and 3 nuts with alcohol in a sonicator for 5 minutes.

- Run a 2.5mm drill bit in the holes for the captive nut retainer screws.

- Run a 5mm drill bit through all of the leadscrew holes in all the straddle ends and straddle carriages.

- The carriages should be very snug on the OpenBeam, but should slide reasonably easily. Run carriages back and forth on a long piece of OpenBeam until they slide easily.

- Line up the MR105zz bearings with their pockets in the straddle ends and run a M5 x 40mm screw them and the straddle end. Place the screw head on the side with the deeper pocket. Place a nut and washer on the M5 screw and tighten to pull in and align the bearings in the straddle end.

- Use the same technique to pull the captive nuts into their pockets in the straddle carriages.

- Thread the M5 x 6mm captive nut retainer screws into the straddle carriages. Do not tighten the screws!

- Tap threads into the carriage holes with the M3 tap or by "plastiforming" threads simply by running a screw into them.

- Thread a single nut onto each of the leadscrews.

- Ensure that enough thread extends from the back of the straddle end to engage two more nuts.

- Hold the properly positioned nut in place while starting the jam nut. Tighten the jam nut in place.

- Again check that there is sufficient threaded rod extending from the end of the straddle end. Adjust if necessary.

- Jam nut the free end of the threaded rod.

- Tap one end of each of the OpenBeam pieces with a M3 tap.

- Gently tap the threaded end of a piece of OpenBeam into each of the straddle ends. Secure in place with a M3 x 10mm flat head socket screw.

- Align the flats on the jam nut and the pocket in a knob and gently tap the opposite end of the threaded rod to engage with the knob.

- Countersink the four holes on the OpenBEam side of one of the carriages (not the vertical carriage). Insert the M3 x 20mm flat head socket screws into the countersunk holes. This is the Z-carriage

- Apply a light coating of grease to the interiors of the carriages.

- Align the captive nut with the threaded rod and slide the carriages onto the pieces of OpenBeam.

- Advance the carriage until the threaded rod is all the way through the carriage and then tighten the captive nut retainer screws.

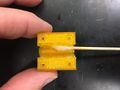

- A completely assembled axis should look as pictured.

- The completely assembled axes should look as pictured.

- Connect the straddle end of the Y axis to the straddle carriage on the X-axis with the four M3 x 25mm socket head capo screws.

- Attach the Z-carriage to the Y-carriage with the four screws that were inserted into the Z-carriage. Tighten the screws step-wise, rotating through each screw to avoid breaking one of the carriages.

-

1. Remove burrs from threaded rod.

-

2. Thoroughly clean threaded rod and 3 nuts.

-

3. Run 2.5mm drill through captive nut retainer screw holes.

-

4. Run a 5.5mm drill bit through leadscrew holes.

-

5. Slide carriage up and down a long piece of OpenBeam.

-

6. Pull bearings into pockets with M5 screw.

-

7. Pull captive nut into carriage.

-

8. Thread in, but do not tighten the captive nut retainers screws.

-

9. Thread a single nut onto the lead screw.

-

10. Check position of nut.

-

11. Start jam nut.

-

12. Check the position again.

-

13. Jam nut free end.

-

14.. Tap OpenBeam end with M3 threads.

-

15 Screw OpenBeam in place.

-

16. Align flats on outer nut and knob and tap into place.

-

17. Install screws in one of the carriages. This is the Z-carriage.

-

18. Apply a small amount of grease to carriage interiors.

-

19. Slide carriages onto OpenBeam.

-

20. Tighten retainer screws.

-

21. Assembled axis.

-

22. Completed set of axes.

-

23. Connected X- and Y-axes.

-

24. All axes assembled.

Assembled piece[edit | edit source]