Methods for how to conduct a LCA for semiconductor recycling during manufacturing will be laid out below.

Methods[edit | edit source]

See Life cycle analysis - MOST for the basic outline of performing an LCA.

LCA for a-Si[edit | edit source]

This project entails doing a LCA for recycling silane in the manufacturing process of a-Si:H-based photovoltaic modules to reduce waste and improve the ecological footprint of PV.

- My scope will be from cradle to production of panels for the laminate a-Si. As I am only taking into account the effect of recycling silane during manufacturing for reuse/resell.

- My main information source will be Photovoltaics by Jungblunth et al. (2009) & it's predecessor LCA of the Photovoltaic System on the Dana Building at U of M by Pacca et al., and the proposed idea by Method for Recycling Silane (SiH4) by Briend et al. (2011)

- The functional unit used is 1 m2 of laminate

- The software used in this study is SimaPro 7.3

- The database used is EcoInvent v2.0

- This database is generally considered reliable, confirmed with the Sustainable Futures Institute Director at Michigan Tech.

The methods for SimaPro shown below will be implored using the data from the stated sources. The following is a quick semi-related example done by myself using SimaPro.

SimaPro v.7.3 - Multi-user[edit | edit source]

Getting into SimaPro[edit | edit source]

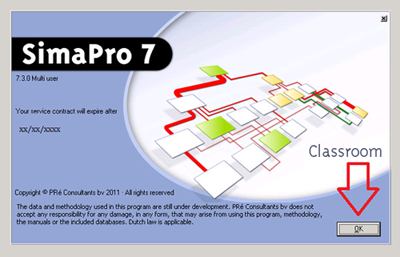

This may be different for different versions/systems, so keep that in mind. After downloading/installing/setting up SimaPro, you should have an icon that looks something like this:

Double click on it to initialize the program. After which you will see the following screen or something similar:

Hit OK.

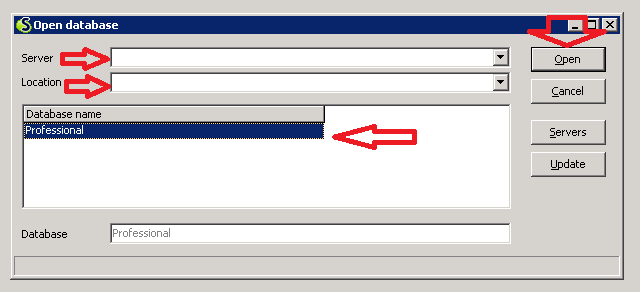

The next screen that pops up will allow you to choose your server, location, & database. As shown below.

The following steps are only valid for multi-user Sima-Pro versions, as far as I know. Select the appropriate server/location/database, click on the database & hit open.

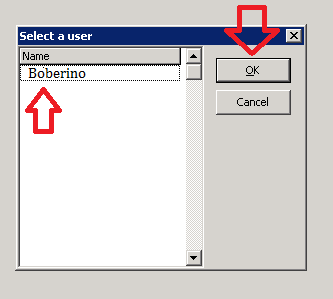

The next window that appears is a "select user" window as shown below.

Select your username & hit OK. It will ask you to input your password, do so & hit OK.

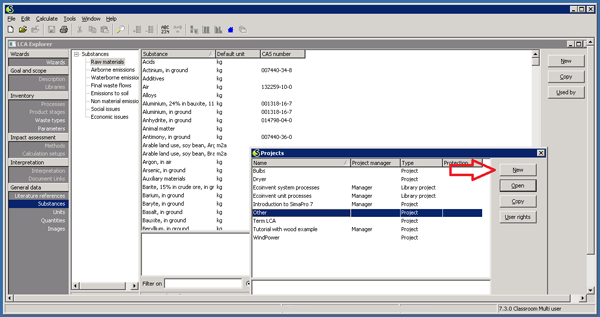

After all of these initial steps, you are ready to either create a new project or open an existing project. I will show the steps to creating a project. (Opening is straightforward, simply click on the project & hit OPEN)

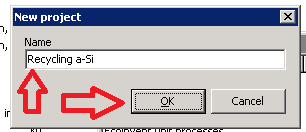

Hit NEW & the following dialog box will open.

Type in your project name & hit OK.

Setting up your project[edit | edit source]

Finally you are ready to begin! The window should look similar to what is shown below:

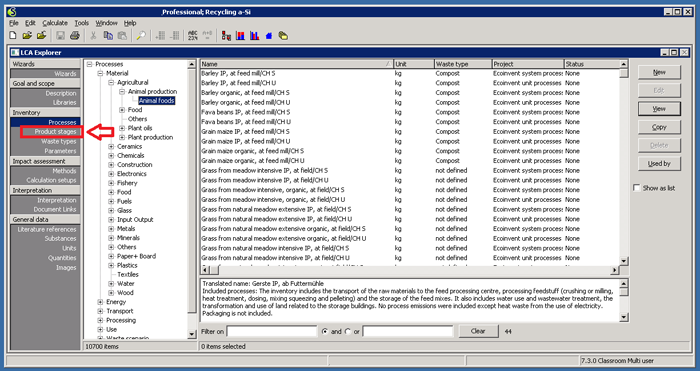

To set up your new project, click "Product Stages" After which the following screen will show up.

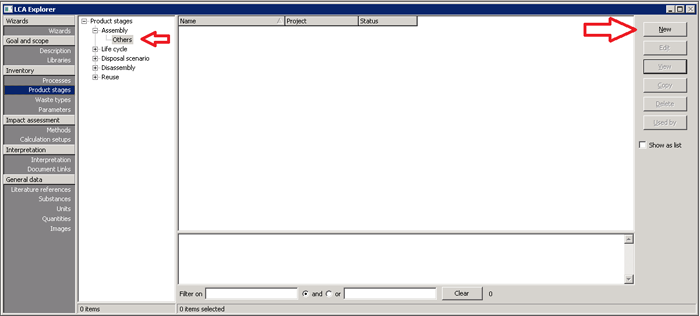

Make sure you highlight "Others" under "Assembly" & hit "NEW"

- Assembly is where you will put all of your manufacturing steps, individual components, etc

- Life Cycle is where you will bring all of your "assemblies" and put in a waste scenario.

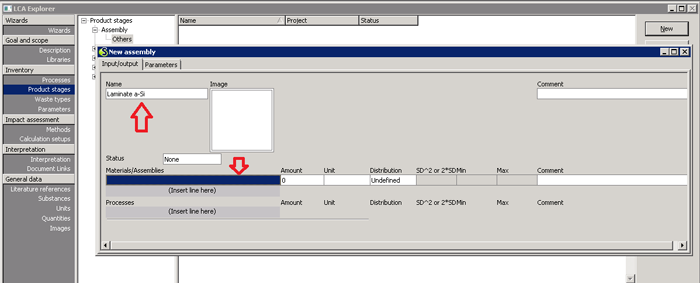

A "New Assembly" window will appear. In this window, title this either a manufacturing step or pre-established component, as shown below.

- Make sure to include all energy/processing if not accounted for in the database entry.

Then double click on "Insert line here" or an open row.

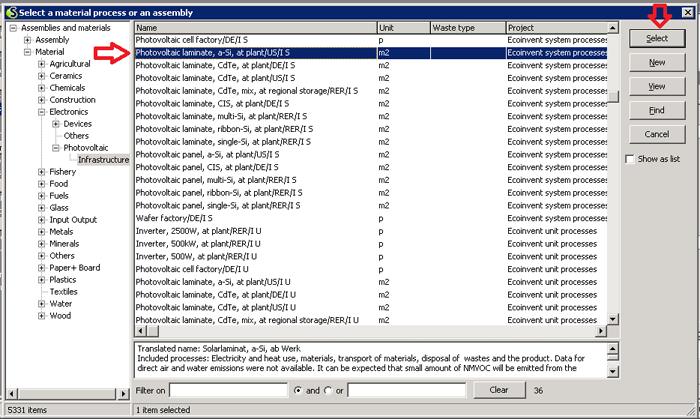

Your database screen will appear, pick the appropriate material/process & pay attention to details on whether this is a raw material, at plant, or other scenario. Also pay attention to the location and units. Make sure to pick from a quality database. Here you see I will pick the pre-established component "Laminate a-Si". Pick material & hit "SELECT"

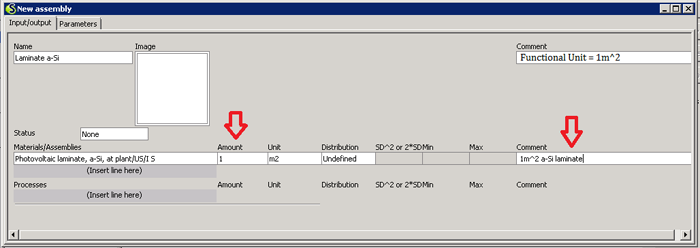

After putting in your first material, it should look something like the window below:

Make sure to input the amount, what units, some comments to explain, & your functional unit in the top right. Close out this "Assembly" window & it will ask you if you want to save, click "SAVE".

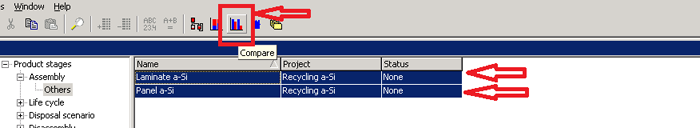

Now your screen should look like this (you can create an additional assembly by going back to the original "Setting up your Assembly" step), as you can see I already created another assembly "Panel a-Si".

You can create "Life Cycle" as well if you have a complex end product, with multiple assemblies. For brevity, I will use the pre-determined values given by the EcoInvent database for these materials. If you choose to create a "Life Cycle" you will need to create a waste scenario as well. Which I will go through in future how-tos/updates.

How to analyze/compare[edit | edit source]

Now you can either compare or analyze!

I will show you how to compare, as analyze is simple. (To analyze simply hit the red/blue bar graph above w/2 bars, then follow steps as defined below)

Highlight your assemblies (Either hold control & click or shift & click). Then hit "Compare", as shown.

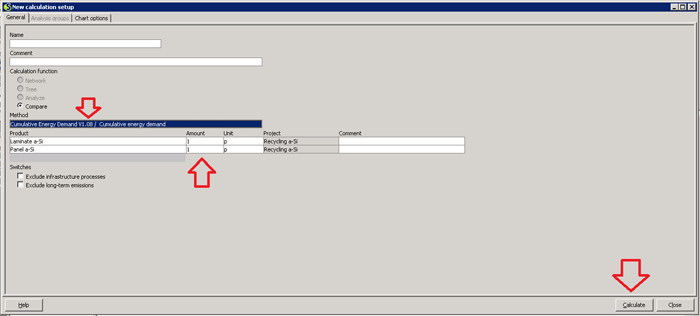

You will get a window that looks similar to the one below. Double click the method area. From this a window will pop up & you can choose what kind of analysis you want to do. Cumulative Energy Demand -compares energy use IPCC GWP..... - affect on climate change and there are several others to choose from. Choose whichever works best for what you want (look up online if you have questions about methods).

Also, make sure that you have equal (or unequal depending on the situation) parts & hit "Calculate" As shown above.

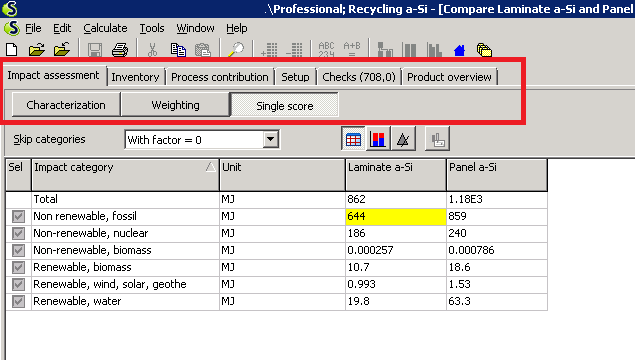

Congratulations! You now have results!

As you can see, since I did a cumulative energy demand comparison of a-Si Laminate vs a-Si Panel. There is a dramatic difference in energy use in MJ between the two. As expected, the panel is much higher due to it incorporating laminate as an input.

Now you can look at the different options for your results, when just doing analysis you get some fun flow charts. Explore these options, then print, print screen or something similar. Now that you've set this up it will be easy to go back & reanalyze the data to get the same results.

Then after you're all finished, close Simapro by going "File->Close".