For main page see: recyclebot and latest version RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

These ideas were generated from the study: Shan Zhong, Pratiksha Rakhe and Joshua M. Pearce. Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System. Recycling 2017, 2(2), 10; doi: 10.3390/recycling2020010 open access

Heating Section[edit | edit source]

- Three heating sections with varied temperature are helpful, which can be obtained by changing the coil density.

- Heating section-2 is in the middle of the heating tube. The temperature on the section-2 should be at a point where the plastic can be totally melted.

- Heating section-1 is on the feeding side and heating section-3 is on the extrusion side. The temperatures on section-1 and section-3 should be slightly lower than that on section-2.<ref>Pettit, G. Plastic extruder temperature control system. U.S. Patent 3,733,059, issued May 15, 1973.<ref>Heating section-1 is for pre-heating the plastic. Plastic after heating section-3 should have enough viscosity to form filament, and the viscosity is varied with temperature for the same plastic.

- The temperature on the nozzle should be close to the temperature on heating section-3. It is important to keep the nozzle with a stable temperature because the nozzle easily loses heat.

Driving Section[edit | edit source]

- The two main purposes for driving system are to deliver plastic and compress plastic.

- To reduce the degradation of the plastic during recycling, it is necessary to decrease the residential time for plastic in the heating tube. It is better to use long heating tubes and rather high auger speeds, which can decrease the residential time and enable the plastic to be heated more consistently. The normal screw rotation speed is 45-210 rpm<ref>Cook, Wayne D., Graeme Moad, Bronwyn Fox, Gary Van Deipen, Tie Zhang, Ferenc Cser, and Lawry McCarthy. Morphology–property relationships in ABS/PET blends. II. Influence of processing conditions on structure and properties. Journal of applied polymer science 1996;62(10):1709-1714.<ref><ref>Chengcheng, Wan, Wang Yilong, and Shen Rui. The Changes of Intrinsic Viscosity of PET Bottle Flakes after Reactive Extrusion. Modern Plastics Processing and Applications 2015;2:007.<ref><ref>Awaja, Firas, Fugen Daver, and Edward Kosior. Recycled poly (ethylene terephthalate) chain extension by a reactive extrusion process. Polymer Engineering & Science 2004;44(8):1579-1587.<ref>.<ref>Oromiehie, Abdulrasoul, and Alireza Mamizadeh. Recycling PET beverage bottles and improving properties. Polymer international 2004;53(6):728-732.<ref>:*If the size of the auger on the nozzle end is slight bigger than other parts, it's better for the auger to compress the plastic in the tube.

Feeding Section[edit | edit source]

- Uniform feeding rate is important for keeping stable temperature and pressure in the heating tube.

- Fluctuating temperature would lead to degradation of the plastic and unstable pressure in the heating tube would result in the variation of the filament diameter which is bad for accurate 3-D printing.

Chain Extender[edit | edit source]

- To recycle the plastic which is easy to degrade, using a chain extender can increase the viscosity of plastic and make it easy to form filament. However, the amount of the chain extender used is usually tiny, so it is difficult but important to make uniform distribution of chain extender in the plastic pellets.

- Some examples of chain extenders for PET cited in the literature are diepoxides, diisocyanates, dianhydrides, bis-oxazolines, carbodiimides, bis-dihydrooxazines<ref>Torres, N., J. J. Robin, and B. Boutevin. Chemical modification of virgin and recycled poly (ethylene terephthalate) by adding of chain extenders during processing. Journal of Applied Polymer Science 2001;79(10): 1816-1824.<ref><ref>Akkapeddi, M. K., and J. Gervasi. Chain extension of PET and nylon in an extruder. In ACS Division of Polymer Chemistry Meeting 1988:567-570.<ref><ref>Inata, Hiroo, and Shunichi Matsumura. Chain extenders for polyesters. I. Addition‐type chain extenders reactive with carboxyl end groups of polyesters. Journal of applied polymer science 1985;30(8):3325-3337.<ref>.<ref>Inata, Hiroo, and Shunichi Matsumura. Chain extenders for polyesters. III. Addition‐type nitrogen‐containing chain extenders reactive with hydroxyl end groups of polyesters. Journal of applied polymer science 1986:32(4):4581-4594.<ref>== See also ==

RepRapable Recyclebot and the Wild West of Recycling[edit source]

Recycling Technology[edit source]

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Open Source 3-D Filament Diameter Sensor for Recycling, Winding and Additive Manufacturing Machines

- Improving recyclebot concepts

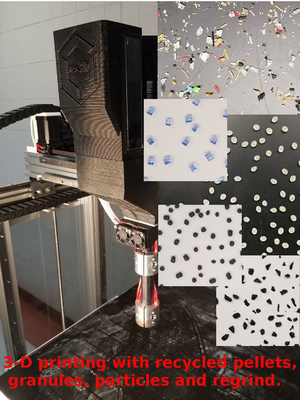

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Multi-material distributed recycling via material extrusion: recycled high density polyethylene and poly (ethylene terephthalate) mixture

- Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Solar powered distributed customized manufacturing

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Open Source Waste Plastic Granulator

- Open-Source Grinding Machine for Compression Screw Manufacturing

- Sustainability and Feasibility Assessment of Distributed E-Waste Recycling using Additive Manufacturing in a Bi-Continental Context

- Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization

- Waste Plastic Direct Extrusion Hangprinter

- Hangprinter for Large Scale Additive Manufacturing using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding

- Open Source Cold and Hot Scientific Sheet Press for Investigating Polymer-Based Material Properties

Distributed Recycling LCA[edit source]

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades

- Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Life cycle analysis of distributed polymer recycling

- Distributed recycling of post-consumer plastic waste in rural areas

- Ethical Filament Foundation

- Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing

- Systems Analysis for PET and Olefin Polymers in a Circular Economy

- Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite

- Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks

Literature Reviews[edit source]

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

- Solar powered recyclebot literature review

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

Externals[edit source]

- Economist article on U. of Washington's HDPE boat, Oprn3dp.me

- https://ultimaker.com/en/resources/52444-ocean-plastic-community-project

- Another possible solution - reusable containers [1]

- Commercial https://dyzedesign.com/pulsar-pellet-extruder/

- ---

- Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [2]

- Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts

- Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing.

- Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [3]

- Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [4]

- O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [5]

- Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [6]

- Romani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://www.mdpi.com/2071-1050/13/13/7269/pdf

References[edit | edit source]