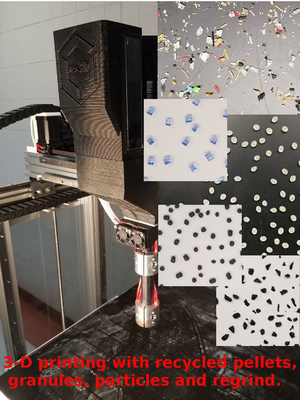

The Michigan furniture industry produces >150 tons/day of wood-based waste, which can be upcycled into a wood polymer composite (WPC). This study investigates the viability of using furniture waste as a feedstock for 3-D printer filament to produce furniture components. The process involves: grinding/milling board scraps made of both LDF/MDF/LDF and melamine/particleboard/paper impregnated with phenolic resins; pre-mixing wood-based powder with the biopolymer poly lactic acid (PLA), extruding twice through open-source recyclebots to fabricate homogeneous 3-D printable WPC filament, and printing with open source FFF-based 3-D printers. The results indicate there is a significant opportunity for waste-based composite WPCs to be used as 3-D printing filament.

- Full open source plans to build a recyclebot

Keywords[edit | edit source]

distributed manufacturing]]; recycling; recyclebot; 3-D printing; polymer filament; wood; wood waste

Post Process[edit | edit source]

Wood Filament Suppliers[edit | edit source]

- https://www.imaginplastics.co.nz/shop/3D+Printing+Filament/Wood-Filled+PLA%3Fcat=00483.html (10% by Weight New Zealand Pine, 90 % INGEO)

- https://www.amazon.com/wood-filament/s?ie=UTF8&page=1&rh=i%3Aaps%2Ck%3Awood%20filament

- https://3dwithus.com/wood-filament

- http://web.archive.org/web/20200807150950/https://woodfilament.com/

- http://www.polymaker.com/shop/polywood/ - wood like but no real wood

- https://3dprintingindustry.com/news/advanced-biocarbon-3d-develops-engineering-grade-wood-based-3d-printer-filament-146227/ - starting from poplar

See also[edit source]

RepRapable Recyclebot and the Wild West of Recycling[edit source]

Recycling Technology[edit source]

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Open Source 3-D Filament Diameter Sensor for Recycling, Winding and Additive Manufacturing Machines

- Improving recyclebot concepts

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Multi-material distributed recycling via material extrusion: recycled high density polyethylene and poly (ethylene terephthalate) mixture

- Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Solar powered distributed customized manufacturing

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Open Source Waste Plastic Granulator

- Open-Source Grinding Machine for Compression Screw Manufacturing

- Sustainability and Feasibility Assessment of Distributed E-Waste Recycling using Additive Manufacturing in a Bi-Continental Context

- Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization

- Waste Plastic Direct Extrusion Hangprinter

- Hangprinter for Large Scale Additive Manufacturing using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding

- Open Source Cold and Hot Scientific Sheet Press for Investigating Polymer-Based Material Properties

Distributed Recycling LCA[edit source]

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades

- Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Life cycle analysis of distributed polymer recycling

- Distributed recycling of post-consumer plastic waste in rural areas

- Ethical Filament Foundation

- Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing

- Systems Analysis for PET and Olefin Polymers in a Circular Economy

- Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite

- Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks

Literature Reviews[edit source]

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

- Solar powered recyclebot literature review

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

Externals[edit source]

- Economist article on U. of Washington's HDPE boat, Oprn3dp.me

- https://ultimaker.com/en/resources/52444-ocean-plastic-community-project

- Another possible solution - reusable containers [1]

- Commercial https://dyzedesign.com/pulsar-pellet-extruder/

- ---

- Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [2]

- Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts

- Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing.

- Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [3]

- Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [4]

- O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [5]

- Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [6]

- Romani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://www.mdpi.com/2071-1050/13/13/7269/pdf

Literature Reviews[edit | edit source]

- Solar powered recyclebot literature review

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

In the media[edit | edit source]

- Kodin jäte voi pian muuttua leluiksi tai käyttöesineiksi – Tältä näyttää 3d-tulostuksen tulevaisuus, joka mullistaa muovin kierrättämisen -- Helsingin Sanomat

- Filamento de madera 3D a partir del reciclado Impresoras 3D

- Michigan Tech Researchers Recycle Wood Furniture Waste into Composite 3D Printing Material 3D Print 49.1k

- Michigan Tech Forscher recyceln Holzmöbelabfälle zu 3D-Druckmaterial aus Verbundwerkstoffen 3D Ruck

- 密歇根技术研究人员将废弃木制家具回收为复合3D打印材料 3D Imperial

- Researchers use industrial wood-waste to make FDM/FFF wood filament 3D Printing Industry 64.3k

- 美 연구팀, 폐기 목재물로 3D프린터 필라멘트 개발 성공 ZDNet (Korea)12k

- Scientists make 3D printable wood filament from furniture waste Wood Working Network 162k

- Filamento de madera 3D a partir del reciclado Impresoras 3D

- 3D printable wood filament from furniture wood-waste Wood Business Portal

- 10 Eco-Friendly 3D Printing Stories From 2018 3D Print