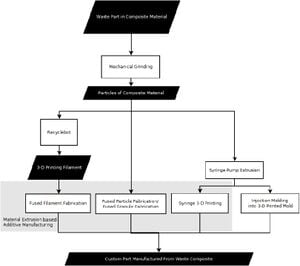

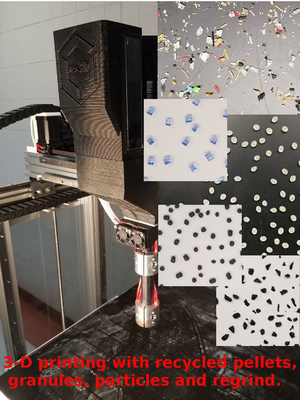

Centralized waste plastic recycling is economically challenging, yet distributed recycling and additive manufacturing (DRAM) provides consumers with direct economic incentives to recycle. This study explores the technical pathways for DRAM of complex polymer composites using a case study of windshield wiper blades. These blades are a thermoplastic composite made up of a soft (flexible) and hard (less flexible) material. The distributed manufacturing methods included mechanical grinding to fused granular fabrication, heated syringe printing, 3-D printed molds coupled to injection molding and filament production in a recyclebot to fused filament fabrication. The particle size, angle of repose, thermal and rheological properties are characterized for the two sub-materials to define the conditions for the extrusion. A successful pathway for fabricating new products was found and the mechanical properties of the resultant components were quantified. Finally, the means to convert scrap windshield wiper blades into useful, high-value, bespoke biomedical products of fingertip grips for hand prosthetics was demonstrated. This study showed that the DRAM model of materials recycling can be used to improve the variety of solutions for a circular economy.

Highlights[edit | edit source]

Distributed recycling and additive manufacturing (DRAM) new pathways.

- Pathways for DRAM of complex polymer composites explored.

- Includes mechanical grinding and various AM methods.

- DRAM can be used to improve the variety of solutions for a circular economy.

See also[edit source]

RepRapable Recyclebot and the Wild West of Recycling[edit source]

Recycling Technology[edit source]

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Open Source 3-D Filament Diameter Sensor for Recycling, Winding and Additive Manufacturing Machines

- Improving recyclebot concepts

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Multi-material distributed recycling via material extrusion: recycled high density polyethylene and poly (ethylene terephthalate) mixture

- Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Solar powered distributed customized manufacturing

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Open Source Waste Plastic Granulator

- Open-Source Grinding Machine for Compression Screw Manufacturing

- Sustainability and Feasibility Assessment of Distributed E-Waste Recycling using Additive Manufacturing in a Bi-Continental Context

- Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization

- Waste Plastic Direct Extrusion Hangprinter

- Hangprinter for Large Scale Additive Manufacturing using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding

Distributed Recycling LCA[edit source]

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades

- Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Life cycle analysis of distributed polymer recycling

- Distributed recycling of post-consumer plastic waste in rural areas

- Ethical Filament Foundation

- Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing

- Systems Analysis for PET and Olefin Polymers in a Circular Economy

- Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite

- Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks

Literature Reviews[edit source]

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

- Solar powered recyclebot literature review

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

Externals[edit source]

- Economist article on U. of Washington's HDPE boat, Oprn3dp.me

- https://ultimaker.com/en/resources/52444-ocean-plastic-community-project

- Another possible solution - reusable containers [1]

- Commercial https://dyzedesign.com/pulsar-pellet-extruder/

- ---

- Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [2]

- Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts

- Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing.

- Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [3]

- Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [4]

- O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [5]

- Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [6]

- Romani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://www.mdpi.com/2071-1050/13/13/7269/pdf