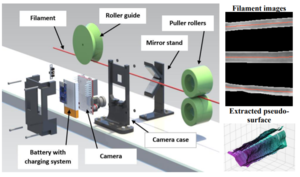

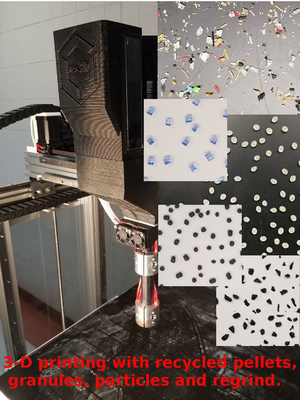

To overcome the challenge of upcycling plastic waste into 3D printing filament in the distributed recycling and additive manufacturing systems, this study designs, builds, tests and validates an open source 3D filament diameter sensor for recycling and winding machines. The modular system for multi-axis optical control of diameter of recycled 3D-printer filament makes it possible to analyze the surface structure of the processed filament, save the history of measurements along the entire length of the spool, as well as mark defective areas. The sensor is developed as an independent module and integrated into recyclebots. It was tested on different kinds of polymers, different sources of plastic and different colors including clear plastic. The results were compared with the manual measurements, and the measurements obtained with a one-dimensional digital light caliper. The results found that the developed open source filament sensing method allows users to obtain significantly more information in comparison with basic one-dimensional light sensors and using the received data not only for more accurate diameter measurements, but also for a detailed analysis of the recycled filament surface. The developed method ensures greater availability of plastics recycling technologies and stimulates the growth of composite materials creation. The presented system can greatly enhance the user possibilities and serve as a starting point for a complete recycling control system that will regulate motor parameters to achieve the desired filament diameter with acceptable deviations and even control the extrusion rate on a printer to recover from filament irregularities.

- Free and open source code: https://osf.io/qdvu8/

Keywords[edit | edit source]

Advanced materials and processing, Control and automation, Process engineering, production systems optimization, Sustainable manufacturing, 3-D printing, additive manufacturing; open-source hardware; RepRap; computer vision; quality assurance; real-time monitoring

See also[edit | edit source]

- OS Computer Vision for Distributed Recycling and Additive Manufacturing

- Additional OS Computer Vision Applications

- Make your own inline filament diameter sensor (under $5)!

- Inline Filament Diameter Estimator, Lowcost (InFiDEL)

See also[edit source]

RepRapable Recyclebot and the Wild West of Recycling[edit source]

Recycling Technology[edit source]

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Open Source 3-D Filament Diameter Sensor for Recycling, Winding and Additive Manufacturing Machines

- Improving recyclebot concepts

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Multi-material distributed recycling via material extrusion: recycled high density polyethylene and poly (ethylene terephthalate) mixture

- Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Solar powered distributed customized manufacturing

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Open Source Waste Plastic Granulator

- Open-Source Grinding Machine for Compression Screw Manufacturing

- Sustainability and Feasibility Assessment of Distributed E-Waste Recycling using Additive Manufacturing in a Bi-Continental Context

- Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization

- Waste Plastic Direct Extrusion Hangprinter

- Hangprinter for Large Scale Additive Manufacturing using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding

Distributed Recycling LCA[edit source]

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades

- Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Life cycle analysis of distributed polymer recycling

- Distributed recycling of post-consumer plastic waste in rural areas

- Ethical Filament Foundation

- Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing

- Systems Analysis for PET and Olefin Polymers in a Circular Economy

- Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite

- Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks

Literature Reviews[edit source]

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

- Solar powered recyclebot literature review

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

Externals[edit source]

- Economist article on U. of Washington's HDPE boat, Oprn3dp.me

- https://ultimaker.com/en/resources/52444-ocean-plastic-community-project

- Another possible solution - reusable containers [1]

- Commercial https://dyzedesign.com/pulsar-pellet-extruder/

- ---

- Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [2]

- Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts

- Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing.

- Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [3]

- Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [4]

- O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [5]

- Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [6]

- Romani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://www.mdpi.com/2071-1050/13/13/7269/pdf

- Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- Slicer and process improvements for open-source GMAW-based metal 3-D printing

- Open source 3-D printing of OSAT

- Real-Time Eye State Detection System for Driver Drowsiness Using Convolutional Neural Network