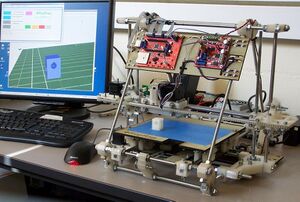

This project is developing, designing and testing of customizable open source hardware applications for the RepRap 3D printer. The designs will be categorized here: OSAT 3D-Printable Designs

Useful: polymer chemical resistance chart

Wohlers Report 2014: the entire global market for 3D printing, including all products and services had the highest compound annual growth rate (CAGR) in 17 years — 34.9% — compared with an average of 27% over the past 26 years and a CAGR for the past three years (2011–2013) of 32.3%. Wohlers Report 2014 values the industry at $3.07 billion last year.[1]

3D Printing Summary[edit | edit source]

- The road ahead for 3-D printers - at PricewaterhouseCoopers, Engineering.com

- an interview with Joshua Pearce

Related Pages[edit | edit source]

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Open source rapid prototyping of OSAT

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Viability of Distributed Manufacturing of Bicycle Components with 3-D Printing: CEN Standardized Polylactic Acid Pedal Testing

- Mechanical testing of polymer components made with the RepRap 3-D printer

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Life cycle analysis of distributed polymer recycling

- Thermal Post-Processing of 3-D Printed Polypropylene Parts for Vacuum Systems

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Mobile Solar Powered 3D Printer

- Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical properties of 3-D printed truss-like lattice biopolymer non-stochastic structures for sandwich panels with natural fibre composite skins