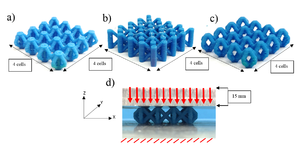

A full mechanical characterisation of three types of 3-D printed lattice cores was performed to evaluate the feasibility of using additive manufacturing (AM) of lightweight polymer-based sandwich panels for structural applications. Effects of the shape of three selected lattice structures on the compression, shear and bending strength has been experimentally investigated. The specimens tested were manufactured with an open source fused filament fabrication-based 3-D printer. These sandwich structures considered had skins made of polypropylene (PP)-flax bonded to the polylactic acid (PLA) lattice structure core using bi-component epoxy adhesive. The PP-flax and the PLA core structures were tested separately as well as bonded together to evaluate the structural performance as sandwich panels. The compression tests were carried out to assess the in-plane and out of plane stiffness and strength by selecting a representative number of cells. Shear band and plastic hinges were observed during the in-plane tests. The shear and three-point bending tests were performed according to the standard to ensure repeatability. The work has provided an insight into the failure modes of the different shapes, and the force-displacement history curves were linked to the progressive failure mechanisms experienced by the structures. Overall, the results of the three truss-like lattice biopolymer non-stochastic structures investigated have indicated that they are well suited to be used for potential impact applications because of their high-shear and out of the plane compression strength. These results demonstrate the feasibility of AM technology in manufacturing of lightweight polymer-based sandwich panels for potential structural uses.

Keywords[edit | edit source]

3D printing; Mechanical testing; Polylactic acid; RepRap; Fused filament fabrication; FDM; Natural fibre ; Lattice structures; PLA; Natural fibre composites; Sandwich structure; Stochastic structures; Biopolymers

See also[edit | edit source]

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing

- Anisotropic mechanical property variance between ASTM D638-14 type I and type IV fused filament fabricated specimens

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Viability of Distributed Manufacturing of Bicycle Components with 3-D Printing: CEN Standardized Polylactic Acid Pedal Testing

- Open source rapid prototyping of OSAT

- RepRap Mechanical Testing Literature Review

- Tensile test protocol: MOST

- Environmental life cycle analysis of distributed 3-D printing and conventional manufacturing of polymer products

- Mechanical testing of polymer components made with the RepRap 3-D printer

- Development and feasibility of applications for the RepRap 3-D printer

- Solar powered distributed customized manufacturing

- MOST RepRap Build

- Applications of RepRap distributed production - literature review

- What is the influence of infill %, layer height and infill pattern on my 3D prints?

- A few ways to strengthen 3D printed parts - STEP 3D (really nice summary of methods to strengthen parts)

- ---

Future

- Toward improvement of the properties of parts manufactured by FFF (Fused Filament Fabrication) through understanding the influence of temperature and rheological behaviour on the coalescence phenomenon http://aip.scitation.org/doi/pdf/10.1063/1.5008034

- ANALYSIS OF EFFECT OF INTERNAL STRUCTURES ON TENSILE STRENGTH OF THE FDM PARTS http://acadpubl.eu/jsi/2017-115-6-7/articles/6/16.pdf