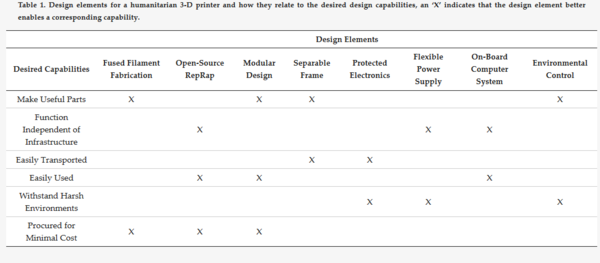

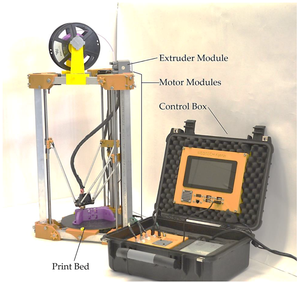

Rapid manufacturing using 3-D printing is a potential solution to some of the most pressing issues for humanitarian logistics. In this paper, findings are reported from a study that involved development of a new type of 3-D printer. In particular, a novel 3-D printer that is designed specifically for reliable rapid manufacturing at the sites of humanitarian crises. First, required capabilities are developed with design elements of a humanitarian 3-D printer, which include, (1) fused filament fabrication, (2) open source self-replicating rapid prototyper design, (3) modular, (4) separate frame, (5) protected electronics, (6) on-board computing, (7) flexible power supply, and (8) climate control mechanisms. The technology is then disclosed with an open source license for the Kijenzi 3-D Printer. A swarm of five Kijenzi 3-D printers are evaluated for rapid part manufacturing for two months at health facilities and other community locations in both rural and urban areas throughout Kisumu County, Kenya. They were successful for their ability to function independently of infrastructure, transportability, ease of use, ability to withstand harsh environments and costs. The results are presented and conclusions are drawn about future work necessary for the Kijenzi 3-D Printer to meet the needs of rapid manufacturing in a humanitarian context.

What could you print with it?

- This printer was primarily tested on 3D printed medical equipment, however there are many applications including:

- The full source for the 3-D Printer is here including BOM, operations manual, software and 3D design files/stls: https://osf.io/pzxea/

- To build: First follow the basic instructions in the manuscript. This design is adapted from basic MOST Delta 3-D printer build that may help with details.

Design Elements and Desired Capabilities[edit | edit source]

See also[edit | edit source]

- Open-source 3-D Printing in Managing Humanitarian Innovation

- Open source rapid prototyping of OSAT

- Mobile Open-Source Solar-Powered 3-D Printers for Distributed Manufacturing in Off-Grid Communities

- Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3-D-Printable Self-Adjustable Glasses

- High-Efficiency Solar-Powered 3-D Printers for Sustainable Development

- 3-D Printing Solar Photovoltaic Racking in Developing World

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Open-source, self-replicating 3-D printer factory for small-business manufacturing

- Distributed manufacturing with 3-D printing: a case study of recreational vehicle solar photovoltaic mounting systems

- Global value chains from a 3D printing perspective

- Self-sufficiency of 3-D printers: utilizing stand-alone solar photovoltaic power systems

- You can upgrade to print with fluids (e.g. silicone) and do PCB milling, etc. using tool head changes developed for other deltas: Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer

Media[edit | edit source]

- 3D Printing Saves the World, Part 1- Machine Design

- Researchers Develop the Kijenzi 3D Printer to Respond to Humanitarian Crises -3D Print.com

- Kijenzi 3D-Drucker der Michigan Tech soll in Krisengebieten Hilfe leisten – und lässt sich im Rucksack verstauen - 3D Grenzenlos (German)

- 究员开发Kijenzi 3D打印机以应对人道主义危机-East Day (China, 228)