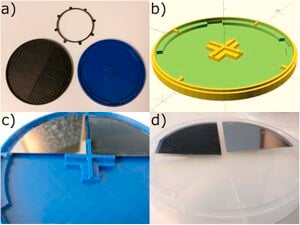

3-D printing has potential to revolutionize manufacturing of customized low-cost scientific equipment, and numerous self-designed applications have already been realized and demonstrated. However, the applicability of 3-D printed devices to cleanrooms used for semiconductor processing is not as straightforward, as the controlled environment sets strict requirements for the allowed materials and items. This work investigates the opportunity to utilize 3-D printing in cleanrooms by analyzing three potentially suitable polymers (polylactic acid (PLA), acrylonitrile butadiene styrene (ABS) and polypropylene (PP)) for two applications that do not require particular chemical compatibility: a custom single wafer storage box and a wafer positioner for a metrology system. The designed equipment supplements commercial selection by introducing support for samples with non-standard shape or size and simultaneously reduces the price of often extensively expensive cleanroom equipment. The results show that the single wafer boxes 3-D printed from PLA and ABS generate as little particles as a commercial equivalent, whereas slightly more particles are found from a wafer stored in the self-printed PP box. Nevertheless, the number of particles on all wafers is in the same order of magnitude, indicating that 3-D printed boxes are not significant particle sources. The 3-D wafer positioner seems to cause a negligible particle increase on the manipulated wafer, while abrasion of the mechanical parts generate larger numbers of particles that may disperse in the environment. Regular cleaning of those parts is thus recommended, and applicability in a cleanroom environment will depend on the cleanliness constraints. Elemental analysis reveals that 3-D printed objects contain no other harmful metal impurities than those originating from colorants. Thus, 3-D printing filaments with natural color should be preferred for purposes, where metal contamination could be an issue, including semiconductor processing. Finally, 3-D printing filaments considered in this study are shown to be resistant to isopropanol and deionized water, which is critical for efficient cleaning for use of 3-D printed objects in cleanrooms. The results demonstrate that simple 3-D printed objects, such as wafer boxes or tweezers, are not notable contamination sources, and hence, are equally suitable for use in cleanrooms as the commercial equivalents.

- Source files for wafer box- Included SCAD and STL files for the wafer box

- Source files for sample positioner box - Included SCAD and STL files for the wafer box

Keywords[edit | edit source]

3-D printing, semiconductor wet processing, custom labware, clean rooms, Cleanroom, Silicon, Semiconductor processing, Polymers, Particle detection,Contamination

See also[edit | edit source]

- Understanding the multilevel phenomena that enables inorganic atomic layer deposition to provide barrier coatings for highly-porous 3-D printed plastic in vacuums

- Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing

- Thermal Post-Processing of 3-D Printed Polypropylene Parts for Vacuum Systems

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Environmental life cycle analysis of distributed 3-D printing and conventional manufacturing of polymer products

- Development and feasibility of applications for the RepRap 3-D printer

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing

- Approaches to Open Source 3-D Printable Probe Positioners and Micromanipulators for Probe Stations

- Vacuum Outgassing Characteristics of Unpigmented 3-D Printed Polymers Coated with ALD Alumina