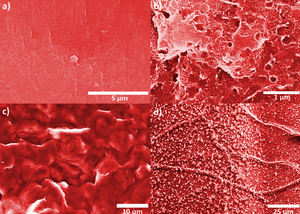

3-D printing offers enormous potential for fabricating custom equipment for space and vacuum systems, but in order to do this at low-costs, polymers are necessary. Historically polymers have not been suited for these applications because of outgassing, but if coated with a conformal, inorganic film introduced with atomic layer deposition (ALD), then outgassing can be reduced. Previous work on coating ALD layers showed promise with heavily outgassing carbon black containing 3-D printed polymers. In this study, ALD aluminum oxide and a commercially available vacuum sealant resin were used to coat clear, acrylonitrile butadiene styrene (ABS), polycarbonate (PC) and polypropylene (PP). Characterization of the films included spectroscopic ellipsometry for thickness, microstructure analysis with scanning electron microscopy, chemical analysis with energy-dispersive X-ray spectroscopy, and residual gas analysis to study relative change in outgassing. ALD-coated samples registered lower pressures than the resin-coated ones. The results showed that the ALD coatings could effectively inoculate unpigmented 3-D printed plastics, which could be used in contamination-sensitive environments such as semiconductor processing systems and space environments.

Keywords[edit | edit source]

3-D printing,chemical compatibility, semiconductor wet processing, custom labware, clean room; vacuum; outgassing; polymer; atomic layer deposition; semiconductor processing

See also[edit | edit source]

- Understanding the multilevel phenomena that enables inorganic atomic layer deposition to provide barrier coatings for highly-porous 3-D printed plastic in vacuums

- Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing

- Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing

- Thermal Post-Processing of 3-D Printed Polypropylene Parts for Vacuum Systems

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Mechanical testing of polymer components made with the RepRap 3-D printer

- Approaches to Open Source 3-D Printable Probe Positioners and Micromanipulators for Probe Stations