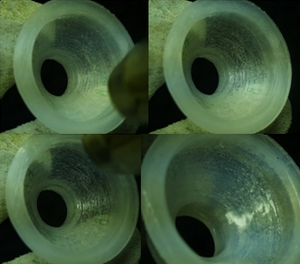

Access to vacuum systems is limited because of economic costs. A rapidly growing approach to reduce costs of scientific equipment is to combine open source hardware methods with digital distributed manufacturing with 3D printers. Although high-end 3D printers can manufacturer vacuum components, again access to tooling is economically prohibitive. Low-cost material extrusion 3D printing with plastic overcomes cost issue, but two problems arise when attempting to use plastic in or as part of vacuum systems: the out gassing of polymers and their sealing. To over-come these challenges, this study explores the potential of using post processing heat treatments to seal 3D printed polypropylene for use in vacuum environments. The effect of infill overlap and heat treatment with a readily-available heat gun on 3D printed PP parts was investigated in detail on ISO-standardized KF vacuum fitting parts and computer vision-based monitoring of vacuum pump down velocities. The results showed that infill overlap and heat treating both had a large impact on the vacuum pressures obtainable with 3D printed parts. Heat treatment combined with 98% infill reliably sealed parts for use in vacuum systems, which makes the use of low-cost desk-top 3D printers capable of manufacturing vacuum components for open scientific hardware.

- OpenSCAD Available online: https://openscad.org

- Heat Treating 3DP Tests, https://osf.io/36jch/

Keywords[edit | edit source]

Fused filament fabrication, Open source 3D printing, open source, RepRap, 3D printing; additive manufacturing; additive manufacturing; vacuum systems; post processing; sealing; vacuum; thermal processing

See also[edit | edit source]

- Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing

- Vacuum Outgassing Characteristics of Unpigmented 3-D Printed Polymers Coated with ALD Alumina

- Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Development and feasibility of applications for the RepRap 3-D printer

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing