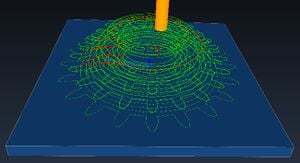

Low-cost gas metal arc welding (GMAW)-based 3-D printing has proven effective at additive manufacturing steel and aluminum parts. Early success, however, was based on hand-writing G-code, which is inadequate for the majority of potential users. To enable automated slicing a 3-D model and generating G-code for an acceptable path for GMAW 3-D printing, this paper reports on upgrading of the free and open source CuraEngine. The new slicer, MOSTMetalCura, provides the following novel abilities necessary for GMAW 3-D printing: i) change the perimeter metric from width to track count, ii) avoid movement that overlaps previous weld beads, iii) have infill start immediately after the perimeter finished and in the direction that eliminates translations, iv) add a variable pause between layers to allow for substrate cooling, v) configure GPIO pins to turn on/off the welder, and vi) set optimized wire feed speed and voltage of the welder based on printing speed, layer height, filament diameter, and tool track width. The process for initiating these changes are detailed and the new slicer is used to help improve the function of the printer for ER70S-6 steel. To find the printing function with the smallest bead width based on volume of material, the line width, layer height, and printing speed are varied to provide wire feed speed calculated by MOSTMetalCura, then the settings are used to print 3-D models. The results of 3-D printing three case study objects of increasing geometric complexity using the process methodology improvements presented, which show resolution of 1 mm bead widths.

- Instructions: MOST Metal Cura

- Source code: https://github.com/mtu-most/MOSTMetalCura

- original source: Ultimaker/CuraEngine (2015) https://github.com/Ultimaker/CuraEngine and Ultimaker/CuraEngine (2015) https://github.com/Ultimaker/CuraEngine

- MOST metal slicing examples https://osf.io/6u5sp/

Keywords[edit | edit source]

3-D printing, gas metal arc weld, GMAW, metal inert gas welding, MIG welding, power monitoring, additive manufacturing;data logging; metal printing;open-source hardware; quality control;RepRap; welder;welding; Open-source slicer, Metal 3-D printing, Low cost metal 3-D printer, Open-source metal 3-D printer, GMAW 3-D printing

See also[edit | edit source]

- Open-source metal 3-D printer

- Applications of Open Source GMAW-Based Metal 3-D Printing

- Open Source Arc Analyzer: Multi-Sensor Monitoring of Wire Arc Additive Manufacturing

- Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- MOST open-source metal 3-D printer v2

- Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing - how to get your print off the substrate with a hammer

- In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing

- Particle Swarm Optimization of Printing Parameters for Open-Source TIG-Based Metal 3D Printing

- Aluminum substrate cleaning for 3-D printing:MOST

- Hypoeutectic Aluminum–Silicon Alloy Development for GMAW-Based 3-D Printing Using Wedge Castings

- Open-source Lab

- Open source 3-D printing of OSAT

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Environmental impacts of distributed manufacturing from 3-D printing of polymer components and products

- Building research equipment with free, open-source hardware

- Delft University of Technology - MIG+ Prusa I3

- Weld 3D - 1st commercial spin off (appears dead, see archived copy)

- see literature on "wire arc additive manufacturing" (WAAM)