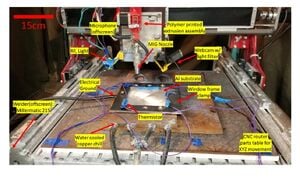

Low-cost high-resolution metal 3-D printing remains elusive for the scientific community. Low-cost gas metal arc wire (GMAW)-based 3-D printing enables wire arc additive manufacturing (WAAM) for near net shape applications, but has limited resolution due to the complexities of the arcing process. To begin to monitor and thus control these complexities, the initial designs of the open source GMAW 3-D printer have evolved to include current and voltage monitoring. Building on this prior work, in this study, the design, fabrication and use of the open source arc analyzer is described. The arc analyzer is a multi-sensor monitoring system for quantifying the processing during WAAM, which includes voltage, current, sound, light intensity, radio frequency, and temperature data outputs. The open source arc analyzer is tested here on aluminum WAAM by varying wire feed rate and measuring the resultant changes in the sensor data. Visual inspection and microstructural analysis of the printed samples looking for the presence of porosity are used as the physical indicators of quality. The value of the sensors was assessed and the most impactful sensors were found to be the light and radio frequency sensors, which showed arc extinction events and a characteristic "good weld" peak frequency.

- Source code: https://osf.io/y85j2/

- Slicing:

- Instructions: MOST Metal Cura

- Source code: https://github.com/mtu-most/MOSTMetalCura

- original source: Ultimaker/CuraEngine (2015) https://github.com/Ultimaker/CuraEngine and Ultimaker/CuraEngine (2015) https://github.com/Ultimaker/CuraEngine

- MOST metal slicing examples https://osf.io/6u5sp/

Keywords[edit | edit source]

3-D printing, gas metal arc weld, GMAW, metal inert gas welding, MIG welding, additive manufacturing;metal printing;open-source hardware; RepRap; welder;welding; Metal 3-D printing, Low cost metal 3-D printer, Open-source metal 3-D printer, GMAW 3-D printing; Wire Arc Additive Manufacturing; WAAM

See also[edit | edit source]

- Open-source metal 3-D printer

- Applications of Open Source GMAW-Based Metal 3-D Printing

- Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- Slicer and process improvements for open-source GMAW-based metal 3-D printing

- MOST open-source metal 3-D printer v2

- Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing - how to get your print off the substrate with a hammer

- In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing

- Particle Swarm Optimization of Printing Parameters for Open-Source TIG-Based Metal 3D Printing

- Open-source Lab