Open-source, self-replicating rapid prototypers (RepRaps) have radically reduced the costs of three-dimensional (3D) printing while expanding its access. Three-dimensional printing's model of distributed manufacturing can produce medical technologies at significantly reduced costs. We investigate this potential by evaluating the viability of an open-source 3D printable infant clubfoot brace.

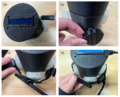

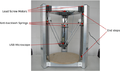

Materials and Methods Starting with a list of key features present in currently available clubfoot braces, a 3D-printed clubfoot brace was developed in free and open-source CAD software (FreeCAD) to enable future customization. Polylactic acid, a biodegradable and recyclable bioplastic, was selected among the various commercial 3D printable materials based on strength and cost.

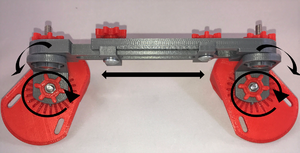

Results The results show that the open-source clubfoot brace matches or surpasses the physical features and mechanical degrees of freedom of all commercial- and nonprofit-developed brace designs while substantially reducing the costs of the braces to hospitals and families.

Conclusions The 3D-printed brace has the features of commercially available braces while significantly reducing the cost, making this clubfoot brace particularly appropriate for use in developing countries. In addition, the results indicated that this model of distributed manufacturing of medical technology is technically and economically appropriate through much of the Global South.

- Models for editing and STLs<ref>https://osf.io/teg2x/<ref>* To edit models see FreeCAD

- How to build Club foot Brace for Infants

- Get help or help someone else - meet at Makers Making Change

See also[edit | edit source]

- Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Distributed Manufacturing of Flexible Products- Technical Feasibility and Economic Viability

- Quantifying the Value of Open Source Hardware Development