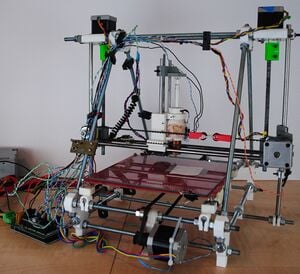

The open-source release of self-replicating rapid prototypers (RepRaps), has created a rich opportunity for low-cost distributed digital fabrication of complex three dimensional objects such as scientific equipment. For example, 3-D printable reactionware devices offer the opportunity to combine open hardware microfluidic handling with lab on a chip reactionware to radically reduce costs and increase the number and complexity of microfluidic applications. To further drive down the cost while improving the performance of lab-on-a-chip paper-based microfluidic prototyping this study reports on the development of a RepRap upgrade capable of converting a Prusa Mendel RepRap into a wax 3-D printer for paper-based microfluidic applications. An open-source hardware approach is used to demonstrate a 3-D printable upgrade for the 3-D printer, which combines a heated syringe pump with the RepRap/Arduino 3-D control. The bill of materials, designs, basic assembly and use instructions are provided along with a completely free and open source software tool chain. The open source hardware device described here accelerates the potential of the nascent field of electrochemical detection combined with paper-based microfluidics by dropping the marginal cost of prototyping to nearly zero while accelerating the turnover between paper-based microfluidic designs.

- This project derived from: MOST Prusa RepRap Build it!

- STL files for 3D printing and OpenSCAD files for editing

- Open Source Software:Franklin

- Example clover print [1]

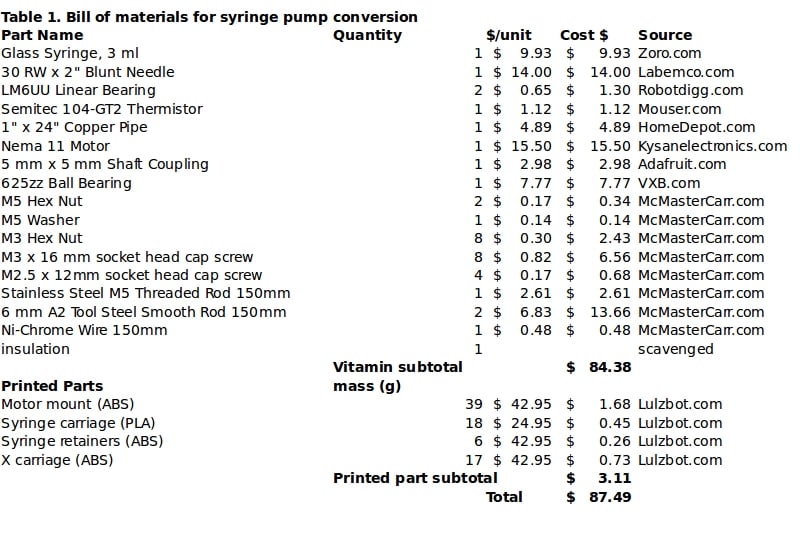

BOM[edit | edit source]

Assembly[edit | edit source]

Refer to paper for overall details.

Prepare components

- File:Prep syringe retainer.odt

- File:Prep carriage.odt

- File:Prep motor assembly.odt

- File:Prep syringe carriage.odt

Assemble

Use[edit | edit source]

To use follow more general instructions here: Open source syringe pump 3-D printer and use open-source Franklin software