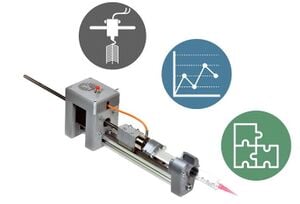

Syringe pumps are widely used in a multitude of tasks where precise volumes of an extrudate need to be delivered at a specific flow rate. In the past decade various open source syringe pump designs have accelerated scientific research and exploration by reducing costs and introducing new ideas. To further expand the capabilities of open source syringe pumps we introduce a novel syringe pump design, the Ystruder. It features a load cell to monitor the piston force. This capability enables clog-detection as well as development of advanced dosing algorithms. The Ystruder can be monitored wirelessly through a browser-based interface that is integrated into the embedded system. The design is modular and simple which facilitates different syringe and motor configurations, to meet a wide range of use cases. Finally, the Ystruder is not limited to functioning solely as a pump as it can be integrated into a wide range of devices such as three-dimensional motion systems. Here the dosing accuracy and repeatability of the Ystruder are quantified, and we demonstrate its functionality both as a syringe pump and a paste extruder for 3D printing.

Keywords[edit | edit source]

3D printing; Open hardware; Open source hardware; Syringe pump; Extruder; Additive manufacturing; Paste extruder;Monitoring; Sensing

See also[edit | edit source]

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Open-source parametric 3-D printed slot die system for thin film semiconductor processing

- Open-source Wax RepRap 3-D Printer for Rapid Prototyping Paper-Based Microfluidics

- Open-source 3-D Platform for Low-cost Scientific Instrument Ecosystem

- Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer

- Open-source syringe pump

- 3-D printed magnetic soft magnetic helical coil actuators of iron oxide embedded polydimethylsiloxane