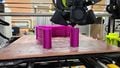

Thermal sterilization is generally avoided for 3-D printed components because of the relatively low deformation temperatures for common thermoplastics used for material extrusion-based additive manufacturing. 3-D printing materials required for high-temperature heat sterilizable components for COVID-19 and other applications demands 3-D printers with heated beds, hot ends that can reach higher temperatures than polytetrafluoroethylene (PTFE) hot ends and heated chambers to avoid part warping and delamination. There are several high temperature printers on the market, but their high costs make them inaccessible for full home-based distributed manufacturing required during pandemic lockdowns. To allow for all these requirements to be met for under $1,000, the Cerberus – an open source three-headed self-replicating rapid prototyper (RepRap) was designed and tested with the following capabilities: i) 200°C-capable heated bed, ii) 500°C-capable hot end, iii) isolated heated chamber with 1kW space heater core and iv) mains voltage chamber and bed heating for rapid start. The Cereberus successfully prints polyetherketoneketone (PEKK) and polyetherimide (PEI, ULTEM) with tensile strengths of 77.5 and 80.5 MPa, respectively. As a case study, open source face masks were 3-D printed in PEKK and shown not to warp upon widely home-accessible oven-based sterilization.

- Source code: https://osf.io/gbjvf/

See also[edit | edit source]

- A review of open source ventilators for COVID-19 and future pandemics

- Open-Source Medical Hardware for Pandemics

- Parametric Nasopharyngeal Swab for Sampling COVID-19 and Other Respiratory Viruses: Open Source Design, SLA 3-D Printing and UV Curing System

- Maximizing Returns for Public Funding of Medical Research with Open-source Hardware

- Economic Potential for Distributed Manufacturing of Adaptive Aids for Arthritis Patients in the U.S.

- 3-D printing open-source click-MUAC bands for identification of malnutrition

- Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Distributed Manufacturing of Flexible Products- Technical Feasibility and Economic Viability

- Quantifying the Value of Open Source Hardware Development

- Low-cost open source ultrasound-sensing based navigational support for visually impaired

- Open-Source Three-Dimensional Printable Infant Clubfoot Brace

- Conversion of Self-Contained Breathing Apparatus Mask to Open Source Powered Air-Purifying Particulate Respirator for Fire Fighter COVID-19 Response

- ---

- $1,700 CREALITY CR-10 LIQUID-COOLING & IKEA MOD ALLOWS 3D PRINTING IN PEEK AND CARBON FIBER

See also COVID-19 resources from MOST[edit | edit source]

- 2020 Michigan Tech Open Sustainability Technology Group COVID19 Projects & Publications

In the News[edit | edit source]

- 可打印高温灭菌PPE的开源3D打印机,为下一次大流行做好准备 Sohu (China) 6

- 可列印高溫滅菌PPE的開源3D印表機,為下一次大流行做好準備 KK News 790

- 可打印高温灭菌PPE的开源3D打印机,为下一次大流行做好准备 Nanjixiong (China)24.6k

- Open Source High-Temperature RepRap 3D Printer Announced Fabbaloo 101k

- Dr. Joshua Pearce's new open-source 'Cerberus' can 3D print PEKK for sub-$1000 3D Printing Industry 67.2k

- Neuer Open-Source 3D-Drucker 'Cerberus' für unter 1000 $ druckt PEKK3D Ruck (German) 432k

- Une machine open-source imprime en 3D du PEKK pour moins de 1 000 dollars3D Natives (France) 52.3k

- Cerberus, open-source 3D printer for less than $1,000 3D Natives 52.3k