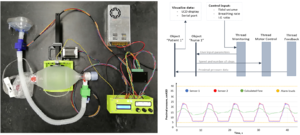

This study describes the development of a simple and easy-to-build portable automated bag valve mask (BVM) compression system, which, during acute shortages and supply chain disruptions can serve as a temporary emergency ventilator. The resuscitation system is based on the Arduino controller with a real-time operating system installed on a largely RepRap 3-D printable parametric component-based structure. The cost of the materials for the system is under $170, which makes it affordable for replication by makers around the world. The device provides a controlled breathing mode with tidal volumes from 100 to 800 milliliters, breathing rates from 5 to 40 breaths/minute, and inspiratory-to-expiratory ratio from 1:1 to 1:4. The system is designed for reliability and scalability of measurement circuits through the use of the serial peripheral interface and has the ability to connect additional hardware due to the object-oriented algorithmic approach. Experimental results after testing on an artificial lung for peak inspiratory pressure (PIP), respiratory rate (RR), positive end-expiratory pressure (PEEP), tidal volume, proximal pressure, and lung pressure demonstrate repeatability and accuracy exceeding human capabilities in BVM-based manual ventilation. Future work is necessary to further develop and test the system to make it acceptable for deployment outside of emergencies such as with COVID-19 pandemic in clinical environments, however, the nature of the design is such that desired features are relatively easy to add with the test using protocols and parametric design files provided.

- Source code[1]

- Open Source License GNU General Public License (GPL) v3.0 and CERN Open Hardware License (OHL) v1.2

- Cost of Hardware < $170

Keywords[edit | edit source]

open hardware, COVID-19, RepRap, 3-D printing, additive manufacturing, medical hardware, open source medical hardware, ventilator, pandemic, ventilation, influenza pandemic, coronavirus, coronavirus pandemic, pandemic ventilator, single-limb, open source, embedded systems, real-time operating system

See also[edit | edit source]

- A review of open source ventilators for COVID-19 and future pandemics

- Open-Source Medical Hardware for Pandemics

- Open Source High-Temperature Reprap for 3-D Printing Heat-Sterilizable PPE and Other Applications

- Parametric Nasopharyngeal Swab for Sampling COVID-19 and Other Respiratory Viruses: Open Source Design, SLA 3-D Printing and UV Curing System

- Maximizing Returns for Public Funding of Medical Research with Open-source Hardware

- Economic Potential for Distributed Manufacturing of Adaptive Aids for Arthritis Patients in the U.S.

- 3-D printing open-source click-MUAC bands for identification of malnutrition

- Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Distributed Manufacturing of Flexible Products- Technical Feasibility and Economic Viability

- Quantifying the Value of Open Source Hardware Development

- Low-cost open source ultrasound-sensing based navigational support for visually impaired

- Open-Source Three-Dimensional Printable Infant Clubfoot Brace

- Conversion of Self-Contained Breathing Apparatus Mask to Open Source Powered Air-Purifying Particulate Respirator for Fire Fighter COVID-19 Response

See also COVID-19 resources from MOST[edit | edit source]

- 2020 Michigan Tech Open Sustainability Technology Group COVID19 Projects & Publications