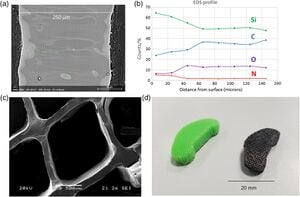

Great advances have been made in various 3D printing methods for ceramics. Fabrication of Si-based ceramics using polymer-derived ceramics (PDCs) is gaining popularity. Using this route, preceramic polymers can be shaped in the polymer state and then pyrolyzed to produce different types of ceramics. Cellular ceramics can be manufactured using this technique. Herein, the novel fabrication of cellular ceramics with a two-step process using PDCs is reported. First cellular structures are 3D printed with fused filament fabrication (FFF) using thermoplastic polyurethane and impregnated with preceramic polymer polysilazane. Second, pyrolysis of the impregnated structure produces a self-similar ceramic cellular structure. The impact of 1) catalysts, 2) curing environment, and 3) pyrolysis sequence optimization to form cellular ceramics with fully dense SiOC(N) struts are systemically evaluated. The resultant custom ceramic components can tolerate operating temperatures of 1500 °C and can be manufactured for less than 5% of the cost of competing methods. The ceramic material is shown to be biocompatible and promotes fast cell adhesion. Finally, early-stage cell activation on the SiOC(N) structure is shown to be tunable by adjusting the porosity with this 3D printing to mimic the bone tissue geometry for bone regeneration.

Keywords[edit | edit source]

polymer derived ceramics; fused filament fabrication; material extrusion; 3D printing; open-source platform,Additive manufacturing, Fused filament fabrication, Open source 3D printing, 3D printing, open hardware, open source, RepRap, Polymer-derived ceramics, Polysilazanes, preceramic polymers, Thermoplastic polyurethanes

See also[edit | edit source]

- Polymer-derived SiOC Replica of Material Extrusion-based 3-D Printed Plastics

- 3D Printed SiOC(N) Ceramic Scaffolds for Bone Tissue Regeneration: Improved Osteogenic Differentiation of Human Bone Marrow‐Derived Mesenchymal Stem Cells

In the News[edit | edit source]

- Scientists successful in slashing ceramic 3D printing costs by 95% using novel approach 3D Printing Industry 72k

- 3D Printing News Briefs 3D Print 78k

- PRINTING CERAMICS MADE EASIER Hackaday 14.9k