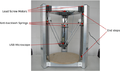

An effective method for the diagnosis of severe acute malnutrition is the measurement of the middle upper arm circumference (MUAC). Current methods to measure MUAC in a pre-hospital setting is through the use of measuring tape indicators, which require users to be trained in how to apply, adjust the tightness and read the device properly. This represents a challenge to using MUACs in many developing world contexts. This study explores the technical viability to overcome some of these challenges with conventional MUAC measurement methods using open source 3-D printable click-MUAC bands.

- Source files both SCAD and STL: [2]

Methods[edit | edit source]

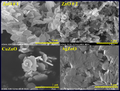

The dimensional accuracy of the open source 3-D printable click MUAC band was quantified with a digital micrometer to ensure reproducibility. The durability is evaluated by putting bands through a deformation test to simulate the use of the band in the field 500 times. The production costs are quantified using the mass of the filament and electricity consumed to manufacture each band.

Findings[edit | edit source]

The click MUAC bands are dimensionally accurate (inner circumferences of +/- 0.50 mm) and durable (surviving 500+ deformations with no notable residual deformation). The 3-D printable click MUAC bands are easier to use and provide a significant cost savings (92% to 97%) when compared to current MUAC measurement methods.

Conclusion[edit | edit source]

The open-source 3-D printed click-MUAC bands offer a viable alternative to the current methods of obtaining MUAC measurements.

See also[edit | edit source]