J.M.Pearce (talk | contribs) m (→Source) |

(Set shorter title-tag for SEO purposes) |

||

| (12 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

{{MOST}} | {{MOST}} | ||

[[File:Blackpc.png|thumb]] | |||

[[ | |||

== | {{Source data | ||

| type = Paper | |||

| cite-as = Ismo T.S. Heikkinen, Giovanni Marin, Nupur Bihari, Craig Ekstrum, Pierce J. Mayville, Yuhuan Fei, Yun Hang Hu, Maarit Karppinen, Hele Savin,Joshua M.Pearce. Atomic layer deposited aluminium oxide mitigates outgassing from fused filament fabrication–based 3-D printed components. ''Surface and Coatings Technology'' 386 (2020) 125459. https://doi.org/10.1016/j.surfcoat.2020.125459 [https://www.academia.edu/41972984/Atomic_layer_deposited_aluminum_oxide_mitigates_out-_gassing_from_fused_filament_fabrication-based_3-D_printed_components open access] | |||

}} | |||

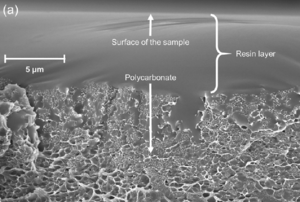

Open-source scientific hardware based on affordable fused filament fabrication (FFF) 3-D printing has the potential to reduce the cost of research tools considerably. So far, development has focused on tools that do not require compatibility with vacuum environments. Highly porous 3-D printed plastics require surface treatments to mitigate their outgassing, and in this study we explored the outgassing reduction from 3-D printed black-colored acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) using a commercial vacuum sealing resin as well as atomic layer deposited (ALD) aluminium oxide (AlOx). The outgassing properties of uncoated plastics could not be measured due to a too high level of outgassing, which was attributed to their high porosity and high specific surface area. However, both the commercial resin and the ALD coatings reduced the extent of outgassing from both ABS and PC, which enabled their comparison by residual gas analysis (RGA). Remarkably, the outgassing performance achieved with ALD AlOx was superior to the performance of the commercial vacuum resin across a temperature range of 40 to 100 °C for both plastics, despite the uneven coverage of the plastic surface with AlOx. Results indicated that both ABS and PC could be made compatible with at least moderate vacuums using ALD AlOx. Thus, the fabrication of laboratory vacuum tools can be realized with affordable 3-D printed plastics. However, further studies on the physical mechanisms behind the outgassing reduction and the durability of the coatings are required. | Open-source scientific hardware based on affordable fused filament fabrication (FFF) 3-D printing has the potential to reduce the cost of research tools considerably. So far, development has focused on tools that do not require compatibility with vacuum environments. Highly porous 3-D printed plastics require surface treatments to mitigate their outgassing, and in this study we explored the outgassing reduction from 3-D printed black-colored acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) using a commercial vacuum sealing resin as well as atomic layer deposited (ALD) aluminium oxide (AlOx). The outgassing properties of uncoated plastics could not be measured due to a too high level of outgassing, which was attributed to their high porosity and high specific surface area. However, both the commercial resin and the ALD coatings reduced the extent of outgassing from both ABS and PC, which enabled their comparison by residual gas analysis (RGA). Remarkably, the outgassing performance achieved with ALD AlOx was superior to the performance of the commercial vacuum resin across a temperature range of 40 to 100 °C for both plastics, despite the uneven coverage of the plastic surface with AlOx. Results indicated that both ABS and PC could be made compatible with at least moderate vacuums using ALD AlOx. Thus, the fabrication of laboratory vacuum tools can be realized with affordable 3-D printed plastics. However, further studies on the physical mechanisms behind the outgassing reduction and the durability of the coatings are required. | ||

== Keywords== | {{Pearce publications notice}} | ||

{{MOST-RepRap}} | |||

== Keywords == | |||

[[3-D printing]],chemical compatibility, semiconductor wet processing, custom labware, clean rooms | [[3-D printing]],chemical compatibility, semiconductor wet processing, custom labware, clean rooms | ||

== See also == | |||

* [[Understanding the multilevel phenomena that enables inorganic atomic layer deposition to provide barrier coatings for highly-porous 3-D printed plastic in vacuums]] | |||

* [[Vacuum Outgassing Characteristics of Unpigmented 3-D Printed Polymers Coated with ALD Alumina]] | |||

* [[Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing]] | * [[Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing]] | ||

* [[Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing]] | * [[Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing]] | ||

| Line 23: | Line 28: | ||

* [[Open source rapid prototyping of OSAT]] | * [[Open source rapid prototyping of OSAT]] | ||

* [[RepRap Mechanical Testing Literature Review]] | * [[RepRap Mechanical Testing Literature Review]] | ||

* [[Environmental life cycle analysis of distributed 3-D printing and conventional manufacturing of polymer products]] | * [[Environmental life cycle analysis of distributed 3-D printing and conventional manufacturing of polymer products]] | ||

* [[Recyclebot]] | * [[Recyclebot]] | ||

* [[Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament]] | * [[Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament]] | ||

* [[Mechanical testing of polymer components made with the | * [[Mechanical testing of polymer components made with the RepRap 3-D printer]] | ||

* [[Development and feasibility of applications for the RepRap 3-D printer]] | * [[Development and feasibility of applications for the RepRap 3-D printer]] | ||

* [[Life cycle analysis of distributed polymer recycling]] | * [[Life cycle analysis of distributed polymer recycling]] | ||

* [[Solar powered distributed customized manufacturing]] | * [[Solar powered distributed customized manufacturing]] | ||

* [[Life cycle analysis of distributed polymer recycling]] | * [[Life cycle analysis of distributed polymer recycling]] | ||

* [[Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing]] | * [[Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing]] | ||

* [[Approaches to Open Source 3-D Printable Probe Positioners and Micromanipulators for Probe Stations]] | * [[Approaches to Open Source 3-D Printable Probe Positioners and Micromanipulators for Probe Stations]] | ||

{{Page data | |||

| title-tag = ALD Aluminum Oxide Mitigates Outgassing in 3-D Printed Parts | |||

}} | |||

[[Category:MOST completed projects and publications]] | [[Category:MOST completed projects and publications]] | ||

| Line 41: | Line 49: | ||

[[Category:Polymers]] | [[Category:Polymers]] | ||

[[Category:Plastic]] | [[Category:Plastic]] | ||

[[ | [[Category:materials]] | ||

Latest revision as of 16:03, 23 February 2024

Open-source scientific hardware based on affordable fused filament fabrication (FFF) 3-D printing has the potential to reduce the cost of research tools considerably. So far, development has focused on tools that do not require compatibility with vacuum environments. Highly porous 3-D printed plastics require surface treatments to mitigate their outgassing, and in this study we explored the outgassing reduction from 3-D printed black-colored acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) using a commercial vacuum sealing resin as well as atomic layer deposited (ALD) aluminium oxide (AlOx). The outgassing properties of uncoated plastics could not be measured due to a too high level of outgassing, which was attributed to their high porosity and high specific surface area. However, both the commercial resin and the ALD coatings reduced the extent of outgassing from both ABS and PC, which enabled their comparison by residual gas analysis (RGA). Remarkably, the outgassing performance achieved with ALD AlOx was superior to the performance of the commercial vacuum resin across a temperature range of 40 to 100 °C for both plastics, despite the uneven coverage of the plastic surface with AlOx. Results indicated that both ABS and PC could be made compatible with at least moderate vacuums using ALD AlOx. Thus, the fabrication of laboratory vacuum tools can be realized with affordable 3-D printed plastics. However, further studies on the physical mechanisms behind the outgassing reduction and the durability of the coatings are required.

Keywords[edit | edit source]

3-D printing,chemical compatibility, semiconductor wet processing, custom labware, clean rooms

See also[edit | edit source]

- Understanding the multilevel phenomena that enables inorganic atomic layer deposition to provide barrier coatings for highly-porous 3-D printed plastic in vacuums

- Vacuum Outgassing Characteristics of Unpigmented 3-D Printed Polymers Coated with ALD Alumina

- Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing

- Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Open source rapid prototyping of OSAT

- RepRap Mechanical Testing Literature Review

- Environmental life cycle analysis of distributed 3-D printing and conventional manufacturing of polymer products

- Recyclebot

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Mechanical testing of polymer components made with the RepRap 3-D printer

- Development and feasibility of applications for the RepRap 3-D printer

- Life cycle analysis of distributed polymer recycling

- Solar powered distributed customized manufacturing

- Life cycle analysis of distributed polymer recycling

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing

- Approaches to Open Source 3-D Printable Probe Positioners and Micromanipulators for Probe Stations