J.M.Pearce (talk | contribs) m (→Source) |

J.M.Pearce (talk | contribs) mNo edit summary |

||

| Line 1: | Line 1: | ||

{{MOST}} | {{MOST}} | ||

{{Pearce-pubs}} | {{Pearce-pubs}} | ||

{{Statusboxtop}} | |||

{{status-design}} | |||

{{status-model}} | |||

{{status-prototype}} | |||

{{status-verified|[[MOST]]}} | |||

You can help Appropedia by contributing to the next step in this [[OSAT]]'s [[:Category:Status|status]]. | |||

{{boxbottom}} | |||

==Source== | ==Source== | ||

* Jacob Franz and Joshua M. Pearce. Open-Source Grinding Machine for Compression Screw Manufacturing. ''Inventions'' 2020, 5(3), 26; https://doi.org/10.3390/inventions5030026 [https://www.academia.edu/43540843/Open-Source_Grinding_Machine_for_Compression_Screw_Manufacturing open access] | * Jacob Franz and Joshua M. Pearce. Open-Source Grinding Machine for Compression Screw Manufacturing. ''Inventions'' 2020, 5(3), 26; https://doi.org/10.3390/inventions5030026 [https://www.academia.edu/43540843/Open-Source_Grinding_Machine_for_Compression_Screw_Manufacturing open access] | ||

Revision as of 14:24, 30 July 2020

Template:Statusboxtop Template:Status-design Template:Status-model Template:Status-prototype Template:Status-verified You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Source

- Jacob Franz and Joshua M. Pearce. Open-Source Grinding Machine for Compression Screw Manufacturing. Inventions 2020, 5(3), 26; https://doi.org/10.3390/inventions5030026 open access

- BOM, CAD, Full source code: https://osf.io/ev6ta/

Abstract

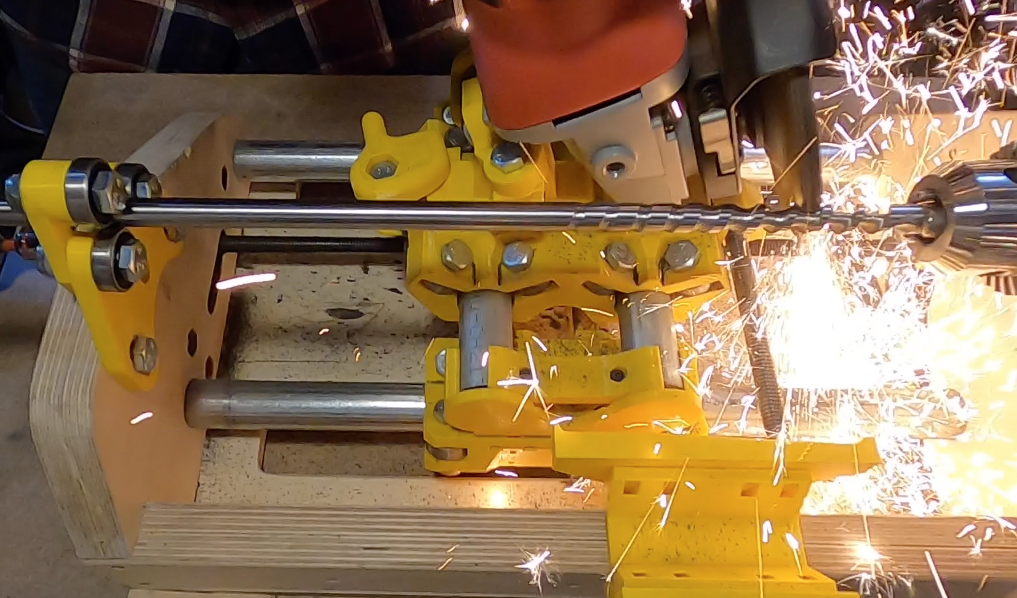

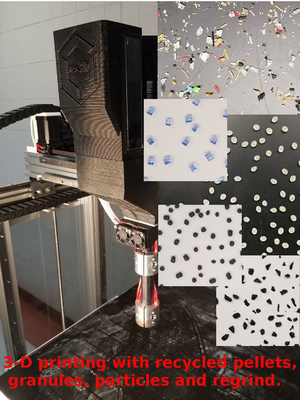

Some of the most promising distributed recycling and additive manufacturing (DRAM) technical systems use fused particle fabrication (FPF) or fused granular fabrication (FGF), where compression screws force post-consumer waste plastic through a heated nozzle for direct 3D printing. To assist the technical evolution of these systems, this study provided the details of an invention for a low-cost, easily replicable open-source grinding machine for compression screw manufacturing. The system itself can be largely fabricated using FPF/FGF following the self-replicating rapid prototyper (RepRap) methodology. This grinding machine can be made from a cordless cut-off grinder and < $155 in parts. The new invention is demonstrated to be able to cut custom screws with variable (i) channel depths, (ii) screw diameters, (iii) screw lengths, (iv) pitches, (v) abrasive disk thicknesses, (vi) handedness of the screws, (vii) and materials (three types of steel tested: 1045 steel, 1144 steel, and 416 stainless steel). The results show that the device is more than capable of replicating commercial screws as well as providing makers with a much greater flexibility to make custom screws. This invention enables the DRAM toolchain to become even more self-sufficient, which assists the goals of the circular economy.

Keywords

| Using the OS Grinding Machine |

|---|

Error in widget YouTube: Unable to load template 'wiki:YouTube' |

grinding machine; open hardware; open-source hardware; open-source appropriate technology; compression screw; grinding; cylindrical grinding machine; material extrusion; angle grinder; [Circular economy]]; Distributed recycling; Polymer recycling; Sustainable development; distributed manufacturing; life cycle analysis; recycling; recyclebot; 3-D printing; Open source hardware; Open hardware; RepRap; Recycling; Polymers; Plastic; Recyclebot; Waste plastic; Composites; Polymer composites; Extruder; Upcycle; Materials science;additive manufacturing; distributed manufacturing; open-source; waste plastic; extruder; upcycle

Project Details of assembly

See also

RepRapable Recyclebot and the Wild West of Recycling

Recycling Technology

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Open Source 3-D Filament Diameter Sensor for Recycling, Winding and Additive Manufacturing Machines

- Improving recyclebot concepts

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical Properties of Direct Waste Printing of Polylactic Acid with Universal Pellets Extruder: Comparison to Fused Filament Fabrication on Open-Source Desktop Three-Dimensional Printers

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Multi-material distributed recycling via material extrusion: recycled high density polyethylene and poly (ethylene terephthalate) mixture

- Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Solar powered distributed customized manufacturing

- Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites

- Open Source Waste Plastic Granulator

- Open-Source Grinding Machine for Compression Screw Manufacturing

- Sustainability and Feasibility Assessment of Distributed E-Waste Recycling using Additive Manufacturing in a Bi-Continental Context

- Finding Ideal Parameters for Recycled Material Fused Particle Fabrication-Based 3D Printing Using an Open Source Software Implementation of Particle Swarm Optimization

- Waste Plastic Direct Extrusion Hangprinter

- Hangprinter for Large Scale Additive Manufacturing using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding

Distributed Recycling LCA

- Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing

- Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades

- Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy

- Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament

- Life cycle analysis of distributed polymer recycling

- Distributed recycling of post-consumer plastic waste in rural areas

- Ethical Filament Foundation

- Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing

- Systems Analysis for PET and Olefin Polymers in a Circular Economy

- Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite

- Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks

Literature Reviews

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

- Solar powered recyclebot literature review

- Waste plastic extruder: literature review

- Life cycle analysis of polymer recycling literature review

Externals

- Economist article on U. of Washington's HDPE boat, Oprn3dp.me

- https://ultimaker.com/en/resources/52444-ocean-plastic-community-project

- Another possible solution - reusable containers [1]

- Commercial https://dyzedesign.com/pulsar-pellet-extruder/

- ---

- Cruz, F., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. [2]

- Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts

- Mohammed, M.I., Das, A., Gomez-Kervin, E., Wilson, D. and Gibson, I., EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing.

- Kariz, M., Sernek, M., Obućina, M. and Kuzman, M.K., 2017. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. [3]

- Kaynak, B., Spoerk, M., Shirole, A., Ziegler, W. and Sapkota, J., 2018. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromolecular Materials and Engineering, p.1800037. [4]

- O. Martikka et al., "Mechanical Properties of 3D-Printed Wood-Plastic Composites", Key Engineering Materials, Vol. 777, pp. 499-507, 2018 [5]

- Yang, T.C., 2018. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), p.976. [6]

- Romani, A., Rognoli, V., & Levi, M. (2021). Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability, 13(13), 7269. https://www.mdpi.com/2071-1050/13/13/7269/pdf