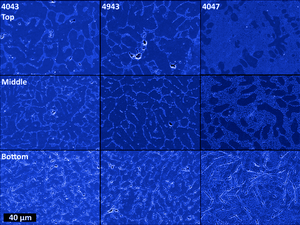

The relationship between microstructure and properties is not widely assessed in parts produced by additive manufacturing, particularly for aluminum. These relationships can be used by engineers to develop new materials, additive processes, and additively manufactured parts for a variety of applications. Thus, the tensile, compressive, and microstructural properties of common aluminum weld filler alloys (ER1100, ER4043, ER4943, ER4047, and ER5356) were evaluated following gas metal arc weld (GMAW)-based metal 3-D printing to identify optimal alloy systems for this type of additive manufacturing. The porosities in all test specimens were found to be less than 2%, with interdendritic shrinkage in 4000 series alloys vs. intergranular shrinkage in 5356. The 4000 series alloys performed better than 1100 and 5356 with respect to printed bead width, porosity, strength, and defect sensitivity. In comparison to standard wrought and weld alloys, the 3-D printed specimens exhibited similar or superior mechanical properties with only minor exceptions. Long print times allow for stress relieving and annealing that improved the print properties of the 4000 series and 5356 alloys. Overall the GMAW-based 3-D parts printed from aluminum alloys exhibited similar mechanical properties to those fabricated using more conventional processing techniques.

Keywords[edit | edit source]

3-D printing; additive manufacturing; aluminum; mechanical properties; tensile test; compression test

Free metal 3-D printer plans[edit | edit source]

- Open-source metal 3-D printer

- MOST open-source metal 3-D printer v2

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer

How to get your print off the substrate with a hammer[edit | edit source]

- In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing

- Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing -

- Aluminum substrate cleaning for 3-D printing:MOST

See also[edit | edit source]

- 3D Metal Printing Slicer Plugin

- Open-source Lab

- Open source 3-D printing of OSAT

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Environmental impacts of distributed manufacturing from 3-D printing of polymer components and products

- Building research equipment with free, open-source hardware

- Delft University of Technology - MIG+ Prusa I3

- Weld 3D - 1st commercial spin off

- see literature on "wire arc additive manufacturing" (WAAM)