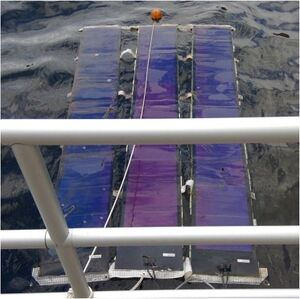

Floating photovoltaic (FPV) technology is gaining prominence as a means to alleviate land use conflicts while obtaining large solar PV deployments and simultaneously reducing evaporated water loss. In this study, an open source after-market distributed manufacturing method is proposed to be applied to large flexible PV modules to make flexible FPV systems. Specifically this study considers surface floating of flexible thin film solar PV using three types of closed-cell foams: i) neoprene, ii) mincell and iii) polyethylene. The fabricated FPV underwent indoor and outdoor tests for flotation, wave resistance, temperature and resistance to algae accumulation. The average operational temperature was reduced by 10–20 °C for the FPV compared to land-based mounting indicating substantial increases in electricity output compared to ground-based deployment of any type of PV (2–4% for amorphous silicon used here and 5–10% for crystalline silicon based PV). In addition, foam-based FPV racking were also found to reduce costs of racking to $0.37–0.61/W, which is significantly lower than raft-based FPV as well as conventional land-based racking. The results of this preliminary study indicate that foam-backed FPV is exceptionally promising and should be further investigated with different foams, larger systems and more diverse deployments for longer periods to increase PV deployments.

- For a literature review on FPV see: Solar floatovoltaics lit review

Keywords[edit | edit source]

Floating photovoltaic; FPV; Flexible; Closed-cell foams; Sustainable development; Open-source; Photovoltaic; Racking

See also[edit | edit source]

- The Greenest Solar Power? Life Cycle Assessment of Foam-Based Flexible Floatovoltaics

- Foam-based floatovoltaics: A potential solution to disappearing terminal natural lakes

- Water Conservation Potential of Self-Funded Foam-Based Flexible Surface-Mounted Floatovoltaics

Open Source Photovoltaic Racking Approaches[edit source]

- Ground-mounted

- Roof-mounted

- FPV