Sophivorus (talk | contribs) m (Text replacement - "project-afiliation" to "project-affiliation") |

Sophivorus (talk | contribs) m (Text replacement - "| completed = " to "| years = ") |

||

| (44 intermediate revisions by 9 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{MOST}} | ||

| | [[File:SWP-hx-con.png|thumb]] | ||

{{Source data | |||

| | | type = Paper | ||

| | | cite-as = David C. Denkenberger and and Joshua M. Pearce. [http://www.mdpi.com/2411-9660/2/2/11 Design Optimization of Polymer Heat Exchanger for Automated Household-Scale Solar Water Pasteurizer]. ''Designs'' '''2018''', 2(2), 11; doi:10.3390/designs2020011 [https://www.academia.edu/36461234/Design_Optimization_of_Polymer_Heat_Exchanger_for_Automated_Household-Scale_Solar_Water_Pasteurizer open access] | ||

}} | }} | ||

{{ | {{Project data | ||

| authors = User:J.M.Pearce | |||

| years = 2018 | |||

| made = Yes | |||

}} | |||

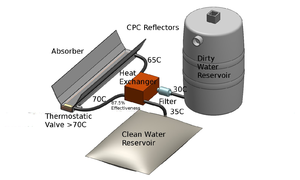

A promising approach to reducing the >870,000 deaths/year globally from unsafe water is flow-through solar water pasteurization systems (SWPs). Unfortunately, demonstrated systems have high capital costs, which limits access for the poor. The most expensive component of such systems is the heat exchanger (HX). Thus, this study focuses on cost optimization of HX designs for flow-through SWPs using high-effectiveness polymer microchannel HXs. The theoretical foundation for the cost optimization of a polymer microchannel HX is provided, and outputs are plotted in order to provide guidelines for designers to perform HX optimizations. These plots are used in two case studies: (1) substitution of a coiled copper HX with polymer microchannel HX, and (2) design of a polymer microchannel HX for a 3-D printed collector that can fit in an arbitrary build volume. The results show that substitution of the polymer expanded HX reduced the overall expenditure for the system by a factor 50, which aids in making the system more economical. For the second case study, the results show how future system designers can optimize an HX for an arbitrary SWP geometry. The approach of distributed manufacturing using laser welding appears promising for HX for SWP. | |||

A promising approach to reducing the >870,000 deaths/year globally from unsafe water is flow-through solar water pasteurization systems (SWPs). Unfortunately, demonstrated systems have high capital costs, which limits access for the poor. The most expensive component of such systems is the heat exchanger (HX). Thus, this study focuses on cost optimization of HX designs for flow-through SWPs using high-effectiveness polymer microchannel HXs. The theoretical foundation for the cost optimization of a polymer microchannel HX is provided, and outputs are plotted in order to provide guidelines for designers to perform HX optimizations. These plots are used in two case studies: (1) substitution of a coiled copper HX with polymer microchannel HX, and (2) design of a polymer microchannel HX for a 3-D printed collector that can fit in an arbitrary build volume. The results show that substitution of the polymer expanded HX reduced the overall expenditure for the system by a factor 50, which aids in making the system more economical. For the second case study, the results show how future system designers can optimize an HX for an arbitrary SWP geometry. The approach of distributed manufacturing using laser welding appears promising for HX for SWP. | |||

{{Pearce publications notice}} | |||

== See also == | |||

* [[Expanded microchannel heat exchanger]] | * [[Expanded microchannel heat exchanger]] | ||

* [[Towards Low-Cost Microchannel Heat Exchangers: Vehicle Heat Recovery Ventilator Prototype]] | * [[Towards Low-Cost Microchannel Heat Exchangers: Vehicle Heat Recovery Ventilator Prototype]] | ||

| Line 45: | Line 25: | ||

* [[Laser welding protocol: MOST]] | * [[Laser welding protocol: MOST]] | ||

* [[Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing]] | * [[Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing]] | ||

* [[Expanded microchannel heat exchanger: Non-destructive evaluation]] | |||

* [[Expanded Microchannel Heat Exchanger: Finite Difference Modeling]] | |||

== Manufacturing the HX with an open source laser welding system == | |||

* [[Experimental Characterization of Heat Transfer in an Additively Manufactured Polymer Heat Exchanger]] | * [[Experimental Characterization of Heat Transfer in an Additively Manufactured Polymer Heat Exchanger]] | ||

* [[Expanded microchannel heat exchanger]] | * [[Expanded microchannel heat exchanger]] | ||

* [[Open-source laser system for polymeric welding]] - open source hardware design | * [[Open-source laser system for polymeric welding]] - open source hardware design | ||

* [[Laser welding protocol: MOST]] - operating instructions | * [[Laser welding protocol: MOST]] - operating instructions | ||

*[[Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds]] | * [[Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds]] | ||

{{Page data | |||

| title-tag = Polymer Heat Exchanger for Solar Water Pasteurizer | |||

| keywords = Distributed manufacturing, heat exchanger, laser welding, microchannel, open hardware, optimization, solar energy, solar thermal, solar water pasteurization, water pasteurization | |||

| sdg = SDG01 No poverty, SDG06 Clean water and sanitation, SDG07 Affordable and clean energy, SDG09 Industry innovation and infrastructure, SDG10 Reduced inequalities | |||

| published = 2018 | |||

| organizations = MTU, Michigan_Tech's_Open_Sustainability_Technology_Lab | |||

| license = CC-BY-SA-3.0 | |||

| language = en | |||

}} | |||

[[Category:MOST completed projects and publications]] | [[Category:MOST completed projects and publications]] | ||

| Line 60: | Line 50: | ||

[[Category:Heating and cooling]] | [[Category:Heating and cooling]] | ||

[[Category:Open source hardware]] | [[Category:Open source hardware]] | ||

[[ | [[Category:designs]] | ||

[[ | [[Category:solar]] | ||

[[ | [[Category:water]] | ||

[[Category:Distributed manufacturing]] | |||

[[Category:Open hardware]] | |||

[[Category:Solar energy]] | |||

Latest revision as of 18:00, 18 June 2024

A promising approach to reducing the >870,000 deaths/year globally from unsafe water is flow-through solar water pasteurization systems (SWPs). Unfortunately, demonstrated systems have high capital costs, which limits access for the poor. The most expensive component of such systems is the heat exchanger (HX). Thus, this study focuses on cost optimization of HX designs for flow-through SWPs using high-effectiveness polymer microchannel HXs. The theoretical foundation for the cost optimization of a polymer microchannel HX is provided, and outputs are plotted in order to provide guidelines for designers to perform HX optimizations. These plots are used in two case studies: (1) substitution of a coiled copper HX with polymer microchannel HX, and (2) design of a polymer microchannel HX for a 3-D printed collector that can fit in an arbitrary build volume. The results show that substitution of the polymer expanded HX reduced the overall expenditure for the system by a factor 50, which aids in making the system more economical. For the second case study, the results show how future system designers can optimize an HX for an arbitrary SWP geometry. The approach of distributed manufacturing using laser welding appears promising for HX for SWP.

See also[edit | edit source]

- Expanded microchannel heat exchanger

- Towards Low-Cost Microchannel Heat Exchangers: Vehicle Heat Recovery Ventilator Prototype

- Open source laser system for polymeric welding

- Laser welding protocol: MOST

- Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing

- Expanded microchannel heat exchanger: Non-destructive evaluation

- Expanded Microchannel Heat Exchanger: Finite Difference Modeling

Manufacturing the HX with an open source laser welding system[edit | edit source]

- Experimental Characterization of Heat Transfer in an Additively Manufactured Polymer Heat Exchanger

- Expanded microchannel heat exchanger

- Open-source laser system for polymeric welding - open source hardware design

- Laser welding protocol: MOST - operating instructions

- Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds

- MOST

- Papers

- Projects

- SDG01 No poverty

- SDG06 Clean water and sanitation

- SDG07 Affordable and clean energy

- SDG09 Industry innovation and infrastructure

- SDG10 Reduced inequalities

- 2018

- MOST completed projects and publications

- Heat exchangers

- Heating and cooling

- Open source hardware

- Designs

- Solar

- Water

- Distributed manufacturing

- Open hardware

- Solar energy