MSE4777 OA and MSE4777 OB/MSE5777/EE4777/EE5777 Open-source 3-D printing provide an introduction to distributed additive manufacturing using open-source 3-D printing.

Description

First this course will provide an overview of open-source hardware and technological development in theory and practice. Both the use of software and user communities will be highlighted and demonstrated. Next, the course will detail the design, use and maintenance of the open-source electronics behind the development of self-replicating rapid prototypers. Then the technological evolution of the open-source 3-D printing technology will be covered with a focus on developing innovation for improved performance and materials selection.

Each student will build a customized RepRap and the course will cover hardware, firmware, slicing and printer controller software for operating and maintaining the device. Finally the material properties, applications and ramifications of RepRap technology will be discussed.

The course is meant for advanced undergraduate and graduate students in Materials Science & Engineering, and Electrical & Computer Engineering, while students in other areas of engineering or science with a strong interest in this topic are also welcomed. Graduate students are expected to complete all coursework assigned to the undergraduates and an in depth project.

- Credits: 3.0

- Lec-Rec-Lab: (3-0-[0-3]), (3 lecture hours and 0-3 lab hours)

- Period: Fall 2019

- 9:35 am - 10:50 am, TR

- 28 G006

- Sept 3, 2019 - Dec 13, 2019

- Instructor: User:J.M.Pearce

- Help with 3-D Printer: https://groups.google.com/a/mtu.edu/forum/?hl=en#!forum/most-delta-users-l then use email: most-delta-users-l@mtu.edu

- Course lectures on Huskycast in Canvas approximately 1.5 hours after class

Why 3-D Printing? A recent report from data company Wanted Analytics found that in one month 35 percent of engineering job listings from a variety of fields, including biomedical, software, and transportation industries, required applicants familiar with 3-D printing.[1] Forbes explains why 3D printing is such a big deal.

Why open source? You will make more money, because OS is more valuable. Recent analysis shows that jobs with the keywords "Microsoft Windows" have an average salary of $64,000, while jobs with the keyword "Linux" have an average salary of $99,000. [2]

Required Course Material

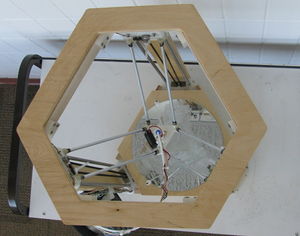

There is a $500 course fee for this course. This fee will be used to purchase a MOST Delta RepRap 2 kit for you to use during the course. At the end of the course you keep the printer you built and modified. The design will be somewhat like the image above - but note that it is a rapidly evolving technology so by Fall the design will have improved.

Textbook: J.M. Pearce, The Open-Source Lab (Elsevier,2014). ISBN: 9780124104624 Other reading will be handouts in class, on-line reading, and emailed pdfs. See hyperlinks in schedule.

Course Organization

This course will be run as an intense seminar meeting as a group. Students will be expected to read the course material before class and actively participate in discussions. The majority of class time will be spent on projects in a flipped class format. Each student will be responsible for building a RepRap 3-D printer to use to complete the projects. Students will be responsible for giving short presentations on their projects on each sub-topic in front of the class at the end of the semester.

Graduate students will take the same lecture and projects as the undergraduates, however, they will also be expected to complete a significant improvement to the RepRap design by the end of the semester. They will demonstrate their mods for the class.

Online students will have identical assignments, but will provide their presentations via YouTube rather than in person.

Class videos are available for all students here.

Learning Objectives

- Learn the fundamentals of additive manufacturing (AM) and 3-D printing with polymers, along with those for emerging materials (e.g., metals, ceramics, flexible materials, nanocomposites, biomaterials) and complex architectures.

- Learn the fundamentals of free and open source hardware (FOSH) design, licensing, and culture.

- Understand and demonstrate the fabrication, maintenance, trouble shooting and operation of self-replicating rapid prototype (RepRap) 3-D printers.

- Understand operating principles, capabilities, and limitations of fused filament fabrication (FFF)-based 3-D printing.

- Understand the principles of "Design for 3-D printing" and compare and contrast additive processes with conventional manufacturing in terms of rate, quality, cost, environmental impact, social control and flexibility.

- Gain hands-on experience with RepRap 3-D printers; use these machines to fabricate example parts of increasing complexity, post-process the parts, and study the results.

- Become familiar with the complete workflow of open source AM, including computational design tools, firmware, software, file formats, toolpath generation, and characterization.

- Understand how to make a new part and alter an existing part for RepRap 3-D printing for custom applications.

- Study applications of distributed manufacturing using 3-D printing including consumer products, scientific equipment, and appropriate technology.

- Place open source 3-D printing in the context of the evolving distributed manufacturing infrastructure.

Grading

| Letter Grade | Percentage | Grade points/credit | Rating |

|---|---|---|---|

| A | 93% & above | 4.00 | Excellent |

| AB | 88%– 92% | 3.50 | Very good |

| B | 82% – 87% | 3.00 | Good |

| BC | 76%– 81% | 2.50 | Above average |

| C | 70% – 75% | 2.00 | Average |

| CD | 65%– 69% | 1.50 | Below average |

| D | 60%- 64% | 1.00 | Inferior |

| F | 59% and below | 0.00 | Failure |

| I | Incomplete; given only when a student is unable to complete a segment of the course because of circumstances beyond the student’s control. A grade of incomplete may be given only when approved in writing by the department chair or school dean. | ||

| X | Conditional,with no grade points per credit; given only when the student is at fault in failing to complete a minor segment of a course, but in the judgment of the instructor does not need to repeat the course. It must be made up within the next semester in residence or the grade becomes a failure (F). A (X) grade is computed into the grade point average as a (F) grade. | ||

Grading Policy

Grades will be based on the following:

| RepRap build | 50 |

| Appropedia user page, 4x mini projects | 50 |

| Educational Aide Project | 200 |

| Science Equipment Project | 250 |

| OSAT Project | 250 |

| Big Money Project or Science Equipment Advanced | 200 |

| Total Points | 1000 |

- Grad students must also complete an improvement to the RepRap OR a 3-D printed automated Scientific Apparatus worth 1000 points and be graded out of 2000.

Late Assignments

Deduct 10% per day, up to 5 working days, then 0 grade. Only exception is for documented illness. Missed projects are penalized by the negative square of the percent total.

Course Policies

Appropriate behavior, attendance, participation and collaboration with your peers on group assignments is expected. Collaboration/Plagiarism Rules Collaboration is encouraged on the group project but the individual project and exams must be completed alone. Calculators are allowed for exams but electronic communication devices are prohibited.

University Policies

Academic regulations and procedures are governed by University policy. Academic dishonesty cases will be handled in accordance the University's policies. If you have a disability that could affect your performance in this class or that requires an accommodation under the Americans with Disabilities Act, please see me as soon as possible so that we can make appropriate arrangements. The Affirmative Action Office has asked that you be made aware of the following: Michigan Technological University complies with all federal and state laws and regulations regarding discrimination, including the Americans with Disabilities Act of 1990. If you have a disability and need a reasonable accommodation for equal access to education or services at Michigan Tech, please call the Dean of Students Office at 487-2212. For other concerns about discrimination, you may contact your advisor, Chair/Dean of your academic unit, or the Affirmative Programs Office at 487-3310.

Course Schedule

Please Note: Readings will be updated periodically before we get to the module.

| Date | Class | Class description | Assignment |

|---|---|---|---|

| 09/03 | 1 | Intro to class, build, big money, grad and mod, assigned | Syllabus, Schedule, M0.1 |

| 09/05 | 2 | Get kits - Start Building Your 3D Printer! | Bring bags/boxes for large part and a sealed container for small parts. Online students go to M&M 714 afternoon. Safety, Start building, M0.2 |

| 09/07 | Bonus Monster Build Class! 8:05 - 16:55 | Help Building Your 3D Printer! | Bring everything. Solder stations, epoxy stations available, M0.2 800 - 1700 Dillman Hall 101 |

| 09/08 | Bonus Monster Build Class! 8:05 - 16:55 | Help Building Your 3D Printer! | Bring everything. Solder stations, epoxy stations available, M0.2 800 - 1700 Dillman Hall 101 |

| 09/10 | 3 | RepRap software chain | M0.3,M0.4 |

| 09/12 | 4 | OSH definitions, development, business | M1.1 |

| 09/17 | 5 | Intro to RepRap, 3D Printing Failure Database (micro project) | M2.1-3 |

| 09/19 | 6 | RepRap community, Printing tricks, Intro to wiki- Appropedia | M2.1-3, Create and populate Appropedia user page Example 4777 user page |

| 09/24 | 7 | RepRap show and tell | RepRap built, BRING IT TO CLASS - post YouTube Video (online students tag it: 777OS3DP) |

| 09/26 | 8 | OpenSCAD Tutorial part 1/ in class micro project MY4777 Rock wall project | M3.3, M3.4, |

| 10/01 | 9 | OpenSCAD Tutorial part 2/ in class micro project - parametric script - Solve Everyone's Problems 777 Customizer project | M3.3, M3.4, |

| 10/03 | 10 | FreeCAD Tutorial/in class micro project lens cover project | M3.5 |

| 10/08 | 11 | MSE4777 Viking mashup project Blender Tutorial/in class micro project lamp shade | M3.2, M0.4 |

| 10/10 | 12 | Microproject show and tell | Appropedia-microprojects due on gallery your userpage, email print failure and bring best microproject printed to class (online students get it to Dr. Pearce's room by drop off or mail) |

| 10/15 | 13 | Mechanical properties of 3-D printed parts, Fix your boards | M3.0 777 Educational Aid assigned |

| 10/17 | 14 | Arduino and automating your prints | M1.3 |

| 10/22 | 15 | OS scientific hardware – lab partners | M4.1, M4.2, 777 OSH Science project 2019 assigned |

| 10/24 | 16 | Educational Aid show and tell | 777 Educational Aid due |

| 10/29 | 17 | Science Teams, OSH Sci Policy | Post lab partners-projects, M4.3 |

| 10/31 | 18 | Science Teams | Science prototype due (online post) |

| 11/05 | 19 | Test prototype, revise, trouble shoot | Graduate students - choose project and list it on MOST Delta mods or Automated 3D printable scientific equipment |

| 11/7 | 20 | Science Show and Tell, 3D printing killer apps | Science revisions due, with data posted NIH/Github/Appropedia Gallery |

| 11/12 | 21 | Open source appropriate technology | 777 OSAT projects 2019 M5.1 |

| 11/14 | 22 | OSAT project | OSAT project chosen, M5.2 |

| 11/19 | 23 | Photogammetry, OSAT Project/Big Money Project-Sci+ | 777 Big Money Project Assigned, M3.7 |

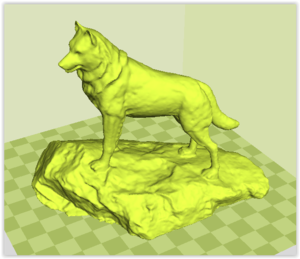

| 11/21 | 24 | Inventive thinking/OSAT Project/ Big Money Project-Sci+ | mech properties ninjaflex M6.1 File:Husky statue.stl Why the world needs deep generalists, not specialists |

| 11/26 | No School Thanksgiving | ||

| 11/28 | No School Thanksgiving | ||

| 12/03 | 25 | Inventive thinking/OSAT Project/ Big Money Project-Sci+ | category:4777 TRIZ 3D printers creative genius |

| 12/05 | 26 | OSAT Show and Tell | OSAT final due |

| 12/10 | 27 | Finish final projects -- OS licenses, legal discussion | Return Loaner Printers M1.2 |

| 12/12 | 28 | Last day – The Future, Money Project-Sci+ and Grad | 777 Big Money Project, Graduate Project Due: MOST Delta mods or Automated 3D printable scientific equipment |

Readings and Media

OSL= Open-Source Lab textbook,class list

Module 0: RepRap Build

- Watch RepRap video, The RepRap project- Ranellucci

RepRap build OSL Chap. 5,Delta Build Overview:MOST,Athena Build Overview, AthenaII, AthenaII-Franklin Troubleshooting, AthenaII part files , Athena board, Need help go here https://groups.google.com/a/mtu.edu/forum/?hl=en#!forum/most-delta-users-l then use email: most-delta-users-l@mtu.edu- Software - Delta Software:MOST(old), Slic3r, Cura, Cura Lulzbot ed., RepRapPro Slicer, tweak AtoZ Cura plugin, Matter Control

- Franklin -- How to Install Franklin on your 777 printer, Franklin use video, Using Franklin (long), Hacking Franklin, Printer controllers - Printrun, Updated Franklin master (Franklin will crash when making changes to settings). http://github.com/phidiasllc/athenaII/tree/master/franklin

- Marlin on AthenaII

- Matter Hackers 3DP troubleshooting guide

Module 1: Introduction to OSH

- OSL Chap. 2 OSH Introduction, Cathedral and Bazaar, Microsoft OSH, OSH intro video, TEDxBoulder - Nathan Seidle (Sparfun)- How Open Hardware will Take Over the World, Lulzbot factory tour and discussion of OSH business by Jeff Moe, The Law of Accelerating Returns by Ray Kurzweil, Do Makers Propose a More Open Source Future? - Idea Channel, PBS Digital Studios, 2015 the Year OSS went nuclear, Can Open-Sourcing Transform Electronics Hardware?, The Economics of OS

- OSL Chap. 3 OS License OS License, Creative Commons copyright licenses, OS software for GNU-Linux, The Future of 3D Printing: Smarter IP Strategies, Less Lawsuits, Right to Repair

- OSL Chap. 4 OS microcontrollers Arduino Tutorials , Makershed comparison, Jeremy Blum TED talk, Nathan Seidle- SparkFun

Module 2: Community

- RepRap IRC, RepRap Forums, RepRap Groups, Lulzbot Forum Hacks

- Arduino Forum, MOST Delta Users

- Free and open repositories of designs, http://www.yeggi.com/ http://www.stlfinder.com/ and now Wikimedia commons

- Tricks: support, raft, parts, orientation, fill, slicer choice, pictorial guide to problems,pictorial guide to reprap print trouble shooting, RichRap Slic3r is Nicer, living hinges, post processing, Nonplanar Slicing

- Appropedia, Example 4777 user page

Module 3: Open source CAD

- Mech strength: Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions, The Effects of PLA Color on Material Properties of 3-D Printed Components, preprint for all materials

- OpenSCAD, OpenSCAD manual, MOST SCAD Libraries on Github, Object oriented OpenSCAD, RapCAD, Aaltoblock, Customizer Thingiverse Format, Intro to OpenSCAD for science lecture notes, GraphsCAD , how to round in openscad using polygons

- Blender, Using Blender to Model for 3-D printing, 2D to 3D in Blender, Creating 3D models for printing with Blender: Advanced tips, Blender Design on Curved Surfaces Tutorial

- FreeCAD, Bram de Vries FreeCAD video tutorials Using OpenSCAD tricks in FreeCAD, OSE FreeCAD

- Tricks - Multicolor, 3D print from McMaster-Carr, 3DHubs - how to optimize design for FFF

- Converting 2D images to 3D for printing using open source software, Images to OpenSCAD Via Inkscape, Celtic Knot SCAD, Bezier curves and knots script for Blender

- MOST Delta mods - see also: Github MTU-MOST repositories, Open-source syringe pump, Open-source metal 3-D printer, MOST mods (incomplete but getting there), another approach to PCB design

- Open Source Photogrammetry, Open source 3D scanners, Lithopanes, Meshroom, Prusa tutorial

- Full control Gcode editor

Module 4: OS Science

- OSL Chap. 1 examples 3D printable science equipment, Tekla Lab requests

- OSL Chap. 5

- OSL Chap. 6

- OSL Chap. 7

Module 5: OSAT

- The Case for Open Source Appropriate Technology

- 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development

- Open source 3-D printing of OSAT

- How 3D Printers Are Boosting Off-The-Grid, Underdeveloped Communities - MotherBoard

- Recyclebot

- Open Source Ecology TED talk

Other resources

- Post processing

- 3DP for injection molding

- MyMiniFactory's Design Handbook

- The Economist-- A third industrial revolution, Where we go from here - types of OS3DP Open-source metal 3-D printer

- Manufacturers demand open 3D printing ecosystem, study shows

- Tips for 3DP poster

- snap fit design tricks

- remix husky statue

Other relevant video material: First International Workshop on "Low-cost 3D Printing for Science, Education and Sustainable Development, 25. Hopes and Fears, 27. Open Hardware and Arduino, 31. Prehistoric Collections: Digitizing the Leaky collection and interesting perspectives on digital rights and proprietary museum collections, 33. Bringing a CAD model into a physical object: Ranelucci video, 54. The future of 3D printing: Another Ranelucci video.

Contests

- School of Technology - Makers Competition: Mary Shelley's 'Frankenstein' Turns 200 Years Old!

- U.S Department of Energy: Additive Manufacturing for Disaster Response

- U.S Department of Energy: Solid State Lighting (SSL) – Additive Manufacturing for Optical Materials

- American Made Solar Prize

Jobs

- How to get a job in 3D printing

- Plastic Bank Internships See:

- Re:3D Internship http://www.re3d.org/careers/

- CNC Router Parts Internship http://www.cncrouterparts.com/

- Aleph Objects (Lulzbot) positions https://www.lulzbot.com/company/job-opportunities and full time jobs http://web.archive.org/web/20191014191327/https://www.alephobjects.com/jobs.html

- Shapeways positions https://www.shapeways.com/jobs

- Open Source Ecology Immersion Program https://wiki.opensourceecology.org/wiki/OSE_Immersion_Program

- OSHWA now 501c3 http://www.oshwa.org/individual-membership/

- Humanitarian Makers on Linked In

- Indeed

- 3D Printing Industry Job Board

- https://uscareers-renishaw.icims.com/jobs/2472/application-engineer/job