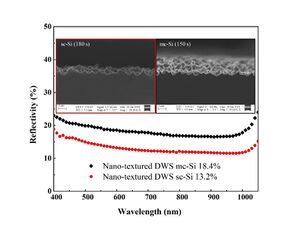

The photovoltaic (PV) industry requires efficient cutting of large single and multi-crystalline (sc- and mc-) silicon (Si) wafers. Historically multi-wire slurry sawing (MWSS) dominated, but the higher productivity of diamond-wire-sawing (DWS) holds promise for decreasing PV costs in the future. While surface texturing of DWS wafers is more complicated than of MWSS wafers, especially in mc-Si wafers, nanotexturing has been shown to overcome this challenge. While the benefit of nanotexturing is thus clearer in mc-Si, a universal nano-texture process that also works on sc-Si would simplify and reduce the investments costs of PV production-lines. In this paper, such a nano-texture process is developed using a metal-assisted chemical etch (MACE) technique. Step-by-step characterization of surface structure and reflectance of the MACE process is used after: 1) wafering, 2) standard acidic texturing etch, 3) silver nanoparticles deposition, and 4) MACE nanotexturing for both sc and mc-Si. The results show that the same MACE process works effectively for both sc-Si and mc-Si wafers. Finally, the nano-textured wafers are processed into PV cells in an industrial process line with conversion efficiencies of 19.4% and 18.7%, for sc-Si and mc-Si solar cells, respectively.

Highlights[edit | edit source]

- Diamond-wire-sawing (DWS) holds promise for decreasing solar costs.

- Explores impact of nanotexturing on DWS sc-Si and mc-Si.

- Nano-texture using a metal-assisted chemical etch (MACE) technique.

- Step-by-step characterization of surface structure and reflectance after each MACE substep.

- Conversion efficiencies of 19.4%, 18.7%, for sc-Si and mc-Si solar cells, respectively.

Keywords[edit | edit source]

Black silicon; Black Si solar cell; Metal-catalyzed chemical etching; Metal-assisted chemical etching; Micro-texture; Nano-texture; Photovoltaic

See also[edit | edit source]

- Influence of metal assisted chemical etching time period on mesoporous structure in as-cut upgraded metallurgical grade silicon for solar cell application

- Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing

- Effects of silver catalyst concentration in metal assisted chemical etching of silicon

- Advances in plasmonic light trapping in thin-film solar photovoltaic devices

- Plasmonic Perfect Meta-Absobers for a-Si PV Devices

- Multi-resonant silver nano-disk patterned thin film hydrogenated amorphous silicon solar cells for Staebler-Wronski effect compensation

- A new method of preparing highly conductive ultra-thin indium tin oxide for plasmonic-enhanced thin film solar photovoltaic devices

- Ambiance-dependent Agglomeration and Surface-enhanced Raman Spectroscopy Response of Self-assembled Silver Nano-particles for Plasmonic Photovoltaic Devices