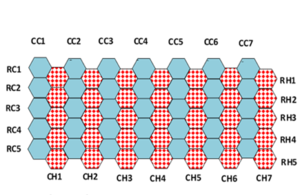

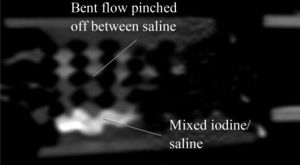

Channels not receiving the same amount of flow (flow maldistribution) is an important effectiveness loss for high effectiveness heat exchangers. This paper develops a finite difference model of a counter flow heat exchanger. For modeled scenarios very good agreement with previous studies and analytical calculations was achieved. For independent pairs of hot and cold channels, as flow rate is reduced, the effectiveness asymptotically approaches the irregularity parameter (a measure of channel flow maldistribution). With thermal coupling between pairs of channels (measured by an equivalent Peclet number), effectiveness continues to increase with decreasing flow rate. These results hold for uncorrelated flow maldistribution on both sides or no flow maldistribution on one side. However, when flow maldistribution is positively correlated, effectiveness is higher; and, when it is negatively correlated, effectiveness is lower. A number of resulting graphs illustrate the effectiveness for each channel with different flow rate and correlation. While one exemplary application is a polymer expanded microchannel heat exchanger, the model could be used for other heat exchangers.

See also[edit | edit source]

- Expanded microchannel heat exchanger

- Expanded microchannel heat exchanger: Non-destructive evaluation

- Towards Low-Cost Microchannel Heat Exchangers: Vehicle Heat Recovery Ventilator Prototype

- Open source laser system for polymeric welding

- Laser welding protocol: MOST

- Open Source Multi-Head 3D Printer for Polymer-Metal Composite Component Manufacturing

Manufacturing the HX with an open source laser welding system[edit | edit source]

- Experimental Characterization of Heat Transfer in an Additively Manufactured Polymer Heat Exchanger

- Expanded microchannel heat exchanger

- Open-source laser system for polymeric welding - open source hardware design

- Laser welding protocol: MOST - operating instructions

- Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds

- Design Optimization of Polymer Heat Exchanger for Automated Household-Scale Solar Water Pasteurizer

- Expanded Microchannel Heat Exchanger: Finite Difference Modeling