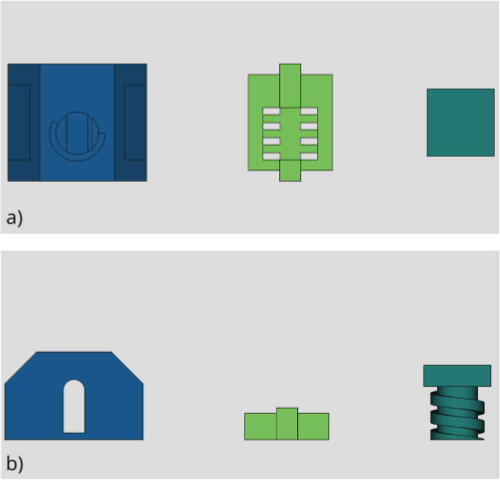

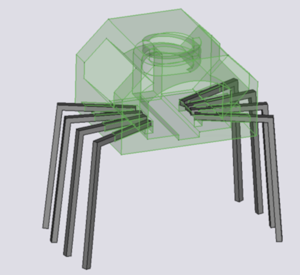

The COVID-19 pandemic exposed the vulnerability of global supply chains of many products. One area that requires improved supply chain resilience and that is of particular importance to electronic designers is the shortage of basic dual in-line package (DIP) electronic components commonly used for prototyping. This anecdotal observation was investigated as a case study of using additive manufacturing to enforce contact between premade, off-the-shelf conductors to allow for electrical continuity between two arbitrary points by examining data relating to the stock quantity of electronic components, extracted from Digi-Key Electronics. This study applies this concept using an open hardware approach for the design, testing, and use of a simple, parametric, 3-D printable invention that allows for small outline integrated circuit (SOIC) components to be used in DIP package circuits (i.e., breadboards, protoboards, etc.). The additive manufacture breakout board (AMBB) design was developed using two different open-source modelers, OpenSCAD and FreeCAD, to provide reliable and consistent electrical contact between the component and the rest of the circuit and was demonstrated with reusable 8-SOIC to DIP breakout adapters. The three-part design was optimized for manufacturing with RepRap-class fused filament 3-D printers, making the AMBB a prime candidate for use in distributed manufacturing models. The AMBB offers increased flexibility during circuit prototyping by allowing arbitrary connections between the component and prototyping interface as well as superior organization through the ability to color-code different component types. The cost of the AMBB is CAD $0.066/unit, which is a 94% saving compared to conventional PCB-based breakout boards. Use of the AMBB device can provide electronics designers with an increased selection of components for through-hole use by more than a factor of seven. Future development of AMBB devices to allow for low-cost conversion between arbitrary package types provides a path towards more accessible and inclusive electronics design as well as faster prototyping and technical innovation.

- Main design files: https://osf.io/dh6uy/

- STLs for printing and design on Thingiverse

- Target group: electronics and electrical engineering prototyping

- Skills required: desktop 3D printing – easy, mechanical assembly – easy