Constructing the Lower Platform[edit | edit source]

Before You Begin[edit | edit source]

- Make sure you have the everything to build the lower platform:

- Hardware:

- 3 – M3x35mm socket head screws

- 3 – M3 ny-lock nuts

- 6 – M3 Flat Washers

- Printed Parts:

- 3 – Motor Ends

- 3 – Platform Spacers

- Required Tools:

- 2.5mm Alan Wrench

- 5.5mm Combination wrench

- Recommended Tools:

- 3mm or 1/8” Drill bit

- Hardware:

Building the lower platform[edit | edit source]

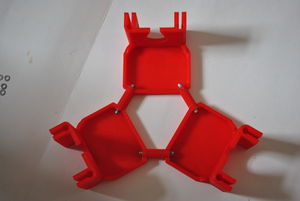

- Take 1 M3 x 35mm and put 1 washer on it. Insert it into one of the two holes opposite the motor mount.

Step One - Slide the screw through the hole in the platform spacer. make sure the flat part is down.

- Place another motor end on the screw after the platform spacer, followed by 1 washer and 1 ny-lock nut. Do not tighten the nut all the way, keep the nut loose, in order to attach the other two platform spacers. Repeat steps 1-3 for the rest of the motor mounts and spacers. Once complete, tighten all the screws and nuts.

Steps 2 & 3 Steps 2 & 3