| Line 152: | Line 152: | ||

== Technical Specifications and Assembly Instructions== | == Technical Specifications and Assembly Instructions== | ||

''' Encoder Connector ''' | ''' Encoder Connector (5 minutes to assemble) ''' | ||

# Print the encoder connector and clean the infill - | # Print the encoder connector and clean the infill - 35mins with 50% infill with Prusa MK3s | ||

# Push the M4 bolt into the middle hole, so the bolt head is recessed | # Push the M4 bolt into the middle hole, so the bolt head is recessed | ||

# Attach nut on the other side | # Attach nut on the other side | ||

# Attach the 3D printed piece onto the motor using 4 M3 bolts | # Attach the 3D printed piece onto the motor using 4 M3 bolts | ||

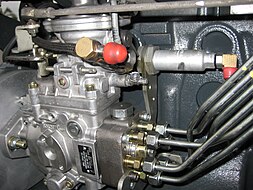

# Should look like | # Should look like the image below | ||

''' Encoder Mount ''' | ''' Encoder Mount (10 minutes to assemble) ''' | ||

# Print the encoder mount for motor housing - 50mins at 15% infill with Prusa MK3s | # Print the encoder mount for motor housing - 50mins at 15% infill with Prusa MK3s | ||

# Use the soldering iron to insert the heat inserts | # Use the soldering iron to insert the heat inserts | ||

| Line 166: | Line 166: | ||

# Attach the encoder to the mount using 2 M2x8 bolts | # Attach the encoder to the mount using 2 M2x8 bolts | ||

# Finally, use this assembly within [[User:ajvincen|Drew's]] motor mount, [[OSHE Growbot Mounting Units]] | # Finally, use this assembly within [[User:ajvincen|Drew's]] motor mount, [[OSHE Growbot Mounting Units]] | ||

# Should look like the image below | |||

{{Gallery | |||

|title=Encoder Mount | |||

|width=135 | |||

|height=180 | |||

|padding=2 | |||

|lines=4 | |||

|align=center | |||

|File:Ajv_motor_housing_close.PNG|Fig 1: Drew's motor housing with encoder installed | |||

|File:Zsa_growbot_encoder.png|Fig 2: Upclose encoder mounting. | |||

}} | |||

''' Motor Testbench ''' | ''' Motor Testbench (40 mins to assemble) ''' | ||

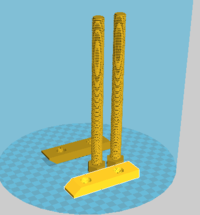

# Print the test bench parts - 4.5 hrs at 15% infill with Prusa MK3s | # Print the test bench parts - 4.5 hrs at 15% infill with Prusa MK3s | ||

# Follow the encoder connector directions | |||

# Follow the encoder mount instructions with 2 M3 inserts instead of 4 | |||

# Attach the motor to the test bench mount using 4 M4x8 bolts | |||

# | # Attach the encoder mount onto the test bench using 2 M3x8 bolts | ||

# | # Should look like the image below | ||

# | {{Gallery | ||

# | |title=Encoder Mount | ||

|width=135 | |||

|height=180 | |||

|padding=2 | |||

|lines=4 | |||

|align=center | |||

|File:Zsa_growbot_testbench.png|Fig 1: Testbench completed. | |||

}} | |||

=== Common Problems and Solutions=== | === Common Problems and Solutions=== | ||

* | * A common mistake is when installing the heat inserts. They need to be flush with the outside of the parts and need to be inserted perpendicular. | ||

== Cost savings== | == Cost savings== | ||

Revision as of 05:41, 5 December 2019

OSHE Growbot Motor Encoders

Project developed by [Zach Arnold]

Template:Statusboxtop Template:Status-design Template:Status-prototype You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Abstract

- This OSAT project was created to assist the senior capstone project for the Open Source Hardware Enterprise, OSHE Growbot. The parts designed are used in conjunction with Drew Vincent's, motor mounts for the Growbot. The Growbot project can be used to fulfill the OSAT 'Zero Hunger' goal.

Bill of Materials

- Motor Encoders File Download

Encoder Connector

| Item | Quantity | Price Per | Price Total |

|---|---|---|---|

| Encoder Connector.stl | 1 | 4.7g | $0.13 |

| M4x20mm | 1 | $0.10 | $0.10 |

| M4 Nut | 1 | $0.15 | $0.15 |

| M3x8mm | 4 | $0.08 | $0.32 |

| Turnigy SK3 6374 Motor [1] | 1 | $83.82 | $83.82 |

Encoder Mount for Motor Housing

| Item | Quantity | Price Per | Price Total |

|---|---|---|---|

| Encoder Mount Motor Housing.stl | 1 | 11g | $0.31 |

| M3 Heat Insert | 4 | $0.20 | $0.80 |

| M2 Heat Insert | 2 | $0.15 | $0.30 |

| M3x10mm | 4 | $0.10 | $0.40 |

| M2x10mm | 2 | $0.07 | $0.14 |

| CUI AMT-102-V [2] | 1 | $23.63 | $23.63 |

Motor Test Bench

| Item | Quantity | Price Per | Price Total |

|---|---|---|---|

| Motor Test Bench V3.stl | 1 | 42g | $1.17 |

| Encoder Mount Motor Test Bench.stl | 1 | 10g | $0.28 |

| M3 Heat Insert | 2 | $0.20 | $0.80 |

| M2 Heat Insert | 2 | $0.15 | $0.30 |

| M4x8 | 4 | $0.09 | $0.36 |

| M3x10mm | 4 | $0.10 | $0.40 |

| M2x10mm | 2 | $0.07 | $0.14 |

| CUI AMT-102-V | 1 | $23.63 | $23.63 |

| Turnigy SK3 6374 Motor | 1 | $83.82 | $83.82 |

Tools needed for fabrication of the OSAT

- MOST Delta RepRap or similar RepRap 3-D printer

- M3 Allen Wrench

- M4 Allen Wrench

- Pliers

- Soldering iron

Technical Specifications and Assembly Instructions

Encoder Connector (5 minutes to assemble)

- Print the encoder connector and clean the infill - 35mins with 50% infill with Prusa MK3s

- Push the M4 bolt into the middle hole, so the bolt head is recessed

- Attach nut on the other side

- Attach the 3D printed piece onto the motor using 4 M3 bolts

- Should look like the image below

Encoder Mount (10 minutes to assemble)

- Print the encoder mount for motor housing - 50mins at 15% infill with Prusa MK3s

- Use the soldering iron to insert the heat inserts

- 2 M2 Heat inserts go into the small holes on the large front face

- 4 M3 Heat inserts go into the holes on the edges

- Attach the encoder to the mount using 2 M2x8 bolts

- Finally, use this assembly within Drew's motor mount, OSHE Growbot Mounting Units

- Should look like the image below

Motor Testbench (40 mins to assemble)

- Print the test bench parts - 4.5 hrs at 15% infill with Prusa MK3s

- Follow the encoder connector directions

- Follow the encoder mount instructions with 2 M3 inserts instead of 4

- Attach the motor to the test bench mount using 4 M4x8 bolts

- Attach the encoder mount onto the test bench using 2 M3x8 bolts

- Should look like the image below

Common Problems and Solutions

- A common mistake is when installing the heat inserts. They need to be flush with the outside of the parts and need to be inserted perpendicular.

Cost savings

- If your solution is not a low cost one then it is not really appropriate.

- Estimate your costs

- Find a commercial equivalent, cite it and put the [url in square brackets]

- Calculate $ savings and % savings

Benefited Internet Communities

- [Open Source Hardware Enterprise | OSHE]

- Name and add links to at least 5 using single brackets around [url name]