Hello, I am Zachary Arnold. I graduated from Michigan Tech during the spring of 2020 with a B.S. in Electrical and Computer Engineering. I enjoy working with circuits and 3D printers. I am currently working full time at General Motors as an Associate Process Engineer on the Controls Execution team within GPS manufacturing engineering.

Interests[edit | edit source]

| Electronics | Open Source | 3D Printers | PLC | IOT | Drones | Manufacturing | Robotics |

| Automation | VLSI | Arduino | CNC | Circuit Design | Tennis | Golf |

Experience[edit | edit source]

- I have built 6 separate 3D printers from a kit. Prusa MK3s, Athena Delta, two deltas, cloner(MakerBot clone), and a Prusa i3 clone.

- I built an MPCNC

- I built an open-source PCB mill

Enterprise[edit | edit source]

Semester 1 Fall 2017

GM Robot Arm Automation:

This semester Dan and I worked on a project to automate a 3D printer. The main aspect of the automation is an open-source robotic arm called Dexter. After 2.5 months, we were able to complete the mechanical part of the arm after jumping many obstacles. We did not receive the electronics until a much later date. Upon obtaining the package of the electronics, we noticed that more parts were missing which is going to set back our timeline once again. Another part of the project is the safety cage that Dan designed. The cage is going to be the main showcase for the automation system where the robotic arm and the printer can work without the risk of injury. The last aspect of the project that I worked on was increasing the ease of removal of prints from the print bed. I designed in CAD and started to print a fan cooling system that, in theory, should speed cool the print bed of the Prusa i3 Mk2 allowing the part to pop off. Our plans for next semester(Spring 2018) is to get the arm moving and programmed, start wiring up the cage with lights and a display system and, lastly, to get prints off the bed easier. All of this should lead to a working demo for Design Expo.

Semester 2 Spring 2018

GM Robot Arm Automation:

This semester Dan, Erica and I worked on the next part of the automation of a 3D printer. I was tasked with learning how to program the arm, wiring the arm, getting Octoprint on a raspberry pi, and creating an Arduino circuit to have the RGB LEDs working on the cage. The RGB circuit was created with old MOSFETs from broken Ramps boards and some pulldown resistors. The board will then connect to the digital pins 9,10,11 on an Arduino mega. Whenever the button is pressed, it cycles between the 6 presets: random red, random green, random blue, strobing random RGB, white and lastly purple. After a couple of long zoom conferences with Haddington Dynamics, we were able to get Dexter moving and completely wired. The wiring was a long task since we had to make sure that the wires did not get strained or pulled within all of Dexter's degrees of freedom. The bulk of the programming was fairly simple with just the angles being changed. The goal for next semester (Fall 2018) is to figure out external feedback from the printer to the robot, add some sort of force sensing with the end effector, and lastly start to allow any size prints. These plans should be a good step in the correct direction to get a fully autonomous 3D printing system.

Images - https://imgur.com/a/42GDrtg

Video - https://www.appropedia.org/File:Michigan_Tech_Open_Source_Hardware_Enterprise_Automation_Demo.mp4

Semester 3 Fall 2018

Lasersaur:

This semester I worked to get the Lasersaur back in working order. I had to redesign all of the mirror mounting methods. This proved to be slightly difficult because I had to make it fit the original 3D printed pieces that were designed previously but the files for it could not be found. I had to reverse engineer the dimensions to get mounting points. I also had to do some updating to all of the wiring and firmware. The Lasersaur is using a Smoothieboard with Smoothieware being the firmware. The firmware was the CNC version of Smoothieware with the laser being enabled. I had to change some of the working size dimensions and the steps per mm to get it more dimensionally accurate. I was able to get the mirrors aligned enough to do a test cut. The next steps are to redesign the gantry due to a random binding issue and to wire all of the endstops correctly. I also need to figure out how to properly align the mirrors because when it gets too far from the edges it becomes out of focus.

-

Fig 1: Overall Lasersaur.

-

Fig 2: Lasersaur electronics.

-

Fig 3: Second laser mirror.

-

Fig 4: Third laser mirror.

-

Fig 5: X gantry belt holder.

-

Fig 6: First cut with laser intensity test.

-

Fig 7: First full cut through a material.

3D Print Service:

This semester I continued the enterprise printing service. I printed a few different things for the ME department and Materials department. At the beginning of the semester, I designed a keychain that we can give out at different events. I went through multiple iterations to make it be the most streamlined, print in 30 minutes, and to fit well in a pocket. Keychain Files

-

Fig 1: Top of the keychain I designed.

-

Fig 2: Bottom of the keychain I designed.

Miscellaneous:

This semester I completed a lot of outreach and increased the team size of the enterprise. At the beginning of the semester, we only had twelve members and now we have twenty members. This semester I also secured a new computer for use within our lab.

-

Fig 1: The new computer set up in the lab.

Semester 4 Spring 2019

Industrial Recyclebot:

This semester Aubrey Woern and I decided to design and build a new filament extruder. The new design is capable of producing 3D printer filament at a quicker and more efficient rate. The main portion of the new design I created was the code and logic for the traversing mechanism. The mechanism will wind filament almost perfectly around the filament spool.

-

Fig 1: Industrial Recyclebot.

-

Fig 2: The first purge of the extruder.

-

Fig 3: Filament going through pulleys.

-

Fig 4: Colorant to be used in filament manufacturing.

-

Fig 5: Extruder and hopper.

-

Fig 6: Extruder die close up.

-

Fig 7: Test print front.

-

Fig 8: Test print back.

3D Print Service:

This semester I continued the enterprise printing service. I printed a few different things for the ME department and other Enterprises on campus. I also mass-printed our keychain with two colors. Towards the middle of the semester, I designed a nametag that we can wear to other events. I went through four iterations to make it the easiest to print and the most readable. Nametag Files

-

Fig 1: Bulk keychain prints.

-

Fig 2: Two colored keychains.

-

Fig 3: The four versions of name tags I designed.

MRRF and Design Expo:

This semester part of the team was able to travel to Goshen, Indiana for the Midwest RepRap Festival. The team was able to meet with other companies and individuals within the community. I also created the design expo poster for this year.

-

Fig 1: Aubrey, Daniel, Erica and I with Josef Prusa at MRRF 2019.

-

Fig 2: The poster created for design expo and to showcase our enterprise.

-

Fig 3: Drew and I manning the expo booth.

Semester 5 Fall 2019

Growbot:

This semester I worked on my senior capstone project, Growbot. For this project, I was the project lead. My tasks were to maintain the budget spreadsheet, order the components, and set up our monthly update meeting with the General Motors mentors. The design work I completed for this project was most of the propulsion system for the robot. I researched and determined the best motor and ESC pair to be used for the robot, which ended up being the Turnigy SK3 6374 149Kv motor and 56v ODrive ESC. I worked closely with the design team to complete various electronic selections to ensure all of the parts will fit. The second half of the semester was experimenting with the motors and encoders. I took a week to design and test a testbench and encoder mounts to start using the motors without the bot. The rest of the time was setting up our Raspberry Pi and establishing a connection to the motors. I was able to successfully move the motors on command and write my own Python script to move the motors. I now just need to update the code to make the bot move in certain directions.

Prusa SL1

September of 2018, the enterprise preordered the Prusa SL1. After patiently waiting over a year the printer arrived. I got the honors of assembling the printer kit. The printer took roughly 5 hours to assemble. The entire assembly process went smoothly and the first print that came off was remarkable. Once we finished print all of the gimmicky prints, I began to try real-life applications. The first print I attempted was an extruder feed gear, which turned out to be unsuccessful. The design I found online seemed to be not to the correct specs, so my next steps are to try and redesign my own feed gear design.

-

Fig 1: Completed SL1 Printer

-

Fig 2: SL1 kit box with resin

-

Fig 3: The printer kit parts

-

Fig 4: Me assembling the printer.

-

Fig 5: First test print with dry-erase cap for scale

-

Fig 6: Tiny husky statue with dry-erase cap for scale

-

Fig 7: Prusa SL1 next to my Prusa MK3s

Semester 6 Spring 2020

This is my final semester in the enterprise. I really enjoyed all of the projects I helped work on. The best part of the enterprise was all of the hands-on experience and industry connections I gained. Sadly my final semester was cut in half due to the COVID-19 outbreak. I was able to get a good portion of my senior design completed and hand the keys over to Lucas Buetler, the new president.

Growbot:

This semester the team was able to get a mostly working robot. The work was sadly cut short due to campus closure from COVID-19. My main contributions this semester was finalizing all of the bot wiring and attaching all of the electronics to the new and improved bot frame. This semester I also worked with Wilson to walk through all of the ideas and how the WebUI should be created. I also worked with Joaquin to improve my soil sensor mechanism. I also assisted Drew in the e-stop relay combination for our motor safety circuitry. The bulk of my work consisted of designing a mechanism to actuate the soil sensor into the ground. I decided to use an Adafruit DRV8833 stepper driver paired with a NEMA11 bipolar stepper motor. The stepper motor is attached to the bot frame with a pinion on the shaft. The pinion is then attached to a rack that has the soil sensor on the end of it. I also needed to come up with a solution to be able to connect multiple I2C sensors to the raspberry pi. I created a small header block which allows me to connect as many sensors and I need. For a more in-depth page regarding the progress of the project, check out our Appropedia page. Growbot

-

Fig 1: Overall Growbot.

-

Fig 2: Voltage sensor board I designed.

-

Fig 3: Voltage sensor board I designed.

-

Fig 4: Soil sensor mechanism.

-

Fig 5: Electronics for the bot that I mounted.

-

Fig 6: Wiring harness I created.

Design Expo

This semester's design expo was a little different. The team had to record their slides to present their work. I was in charge of the Growbot slides and the introduction to the enterprise. I have attached the video for your viewing. Design Expo 2020

Open Source 3-D Printing Class[edit | edit source]

Mini Projects

-

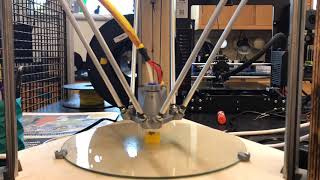

A picture of your operational 3-D printer

-

3D Printing Failure Database, Underextrusion with Quincy mine model

Big Projects

Personal Projects[edit | edit source]

Ant PCB Mill:

Over the summer of 2019, I started to print all of the components to create the ANT PCB Mill. The ANT PCB Mill is an open-source, core XY gantry PCB mill which is mostly 3D printed. The overall footprint of the device is 200mm x 200mm x 100mm. I am going to use this new tool to start learning the process behind making my own PCBs. ANT PCB Files

OpenRC F1:

At the beginning of May 2019, I printed and completed the OpenRC F1 car. It was printed on my Prusa MK3s using AmazonBasics yellow PLA, Prusament galaxy black PLA, and black Ninjaflex. The entire build took around 1 hour, the print around 120 hours of printing. OpenRC F1 Files

-

Fig 1: OpenRC F1.

-

Fig 2: Front view.

-

Fig 3: Top view.

-

Fig 4: Another top view.

-

Fig 5: Back view.

MPCNC:

Over the summer of 2018, I built the mostly printed CNC. It was a quick and easy build. MPCNC Files

-

Fig 1: Overall MPCNC.

-

Fig 2: Electronics side of MPCNC.

-

Fig 3: Toolhead of the MPCNC.

-

Fig 4: First use of CNC, pen tool drawing the MTU logo.

3D Printed Drone:

Over the winter break 2018, I built the drone released on the Prusa website. Drone Files

-

Fig 1: Parts of the drone.

-

Fig 2: Drone completed.