Source

- Oberloier, S. and Pearce, J.M. Belt-Driven Open Source Circuit Mill Using Low-Cost 3-D Printer Components, Inventions 2018, 3(3), 64; https://doi.org/10.3390/inventions3030064 open access

- bill of materials (BOM) available at https://osf.io/mf78v/

Abstract

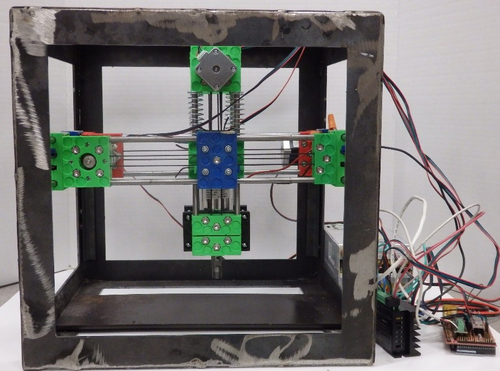

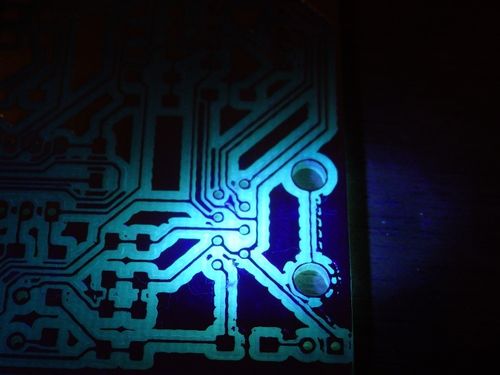

Barriers to inventing electronic devices involve challenges of iterating electronic designs due to long lead times for professional circuit board milling or high costs of commercial milling machines. To overcome these barriers, this study provides open source (OS) designs for a low-cost circuit milling machine. First, design modifications for mechanical and electrical subsystems of the OS Distributed 3-D (D3D) Robotics prototyping system are provided. Next, Copper Carve, an OS custom graphical user interface, is developed to enable circuit board milling by implementing backlash and substrate distortion compensation. The performance of the OS D3D circuit mill is then quantified and validated for: positional accuracy, cut quality, feature accuracy, and distortion compensation. Finally, the return on investment is calculated for inventors using it. The results show by properly compensating for motion inaccuracies with Copper Carve, the machine achieves a motion resolution of 10 microns, which is more than adequate for most circuit designs. The mill is at least five times less expensive than all commercial alternatives and the material costs of the D3D mill are repaid from fabricating 20–43 boards. The results show that the OS circuit mill is of high-enough quality to enable rapid invention and distributed manufacturing of complex products containing custom electronics.

Template:Statusboxtop Template:Status-design Template:Status-model Template:Status-prototype Template:Status-verified You can help Appropedia by contributing to the next step in this OSAT's status. Template:Boxbottom

Keywords

open source hardware; open hardware; RepRap; 3D printing; OpenSCAD; customization; open science hardware; OScH; free and open-source hardware; FOSH; free and open-source software; custom designs; distributed manufacturing; P2P; P2P manufacturing; open design; scientific equipment; open scientific hardware; 3-D printing; circuit milling; circuit design; distributed manufacturing; electronics; electronics prototyping

See Also

- General Design Procedure for Free and Open-Source Hardware for Scientific Equipment

- Open Source Lab

- Building research equipment with free, open-source hardware

- Open source science

- Open-source hardware

What can you build with it?

In the news

- Open-source hardware could defend against the next generation of hacking The Conversation 3090,

San Francisco Chronicle 1386, Chicago Tribune 2,199, NY Daily News 2447, Salon 4764, Indian TV News 6.4k, Washington Top News (WTop) 12.1k, Albany Times Union 24k, NWI Times 42.7k, Billings Gazette 63.9k, Government Tech 64.6k, TechXplore 73.3k, Globe Gazette, The Fifth Domain, GCN, Bozeman Daily Chronicle, Idaho Press, Montana Post, Los Angeles Post, Stuff Magazine, PhilStockWorld, Homeland Security Newswire Blogorama 72k

- We love ideas like this: Open-source hardware could defend against the next generation of hacking CTO Vision

- Top open source projects in 2018, open source hardware, donation model for sustaining open source projects, and more news Opensource.com

- How open source hardware increases security - Opensouce.com 15.3k

- How Open Source Hardware Increases Cybersecurity Open Health News