Goal[edit | edit source]

The main goal of this literature review is to define a standardized step-by-step procedure for designing a twin-screw extruder. This page is dedicated to Fast's plastic waste to food project under supervision of Prof.Joshua M Pearce.

Concepts[edit | edit source]

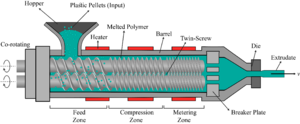

The twin-screw extruder is composed of the following components: hopper, barrel, variable screw speed and temperature control, electrical motor, and replaceable dies for producing products with varying sizes and forms. The schematic diagram of a twin-screw extruder is illustrated in figure 1.

Background (Arranged chronologically)[edit | edit source]

The historical development of the counter-rotating twin-screw extruder[edit | edit source]

Summarize: Schneider[1] historically reviewed the evolution progress of the counter-rotating twin-screw extruder, which was originally developed in the early 1950s by Anton and Wilhelm Anger, who built a twin-screw extruder with a length of 12*D by overcoming the problem of joining pipes by means of plastic. After two decades of advancement in twin-screw extruder technology, the two most active companies namely Thyssen and Rheinstahl merged in 1972 and Thyssen Plastik Maschinen (TPM) was started its work by developing a new parallel model of twin-screw extruder series in 1976 with screw diameters of 50, 60, 85, 107, 130 as well as 160 mm. To resolve the issue of safely, adjusting the radial and axial forces in parallel models, and conical twin-screw extruders were developed that had design benefits for shaping the distributor drive. The first model was designed by Anger (AGM) in 1964, which was called single conical screws. A double conical screw was introduced by Krauss-Maffei In 1974, in which the flight depth declines constantly from the feed section to the metering section, and consequently, the output rate will increase. A little later, Krauss-Maffei proposed a multi-screw extruder in 1974, which was suitable for producing large pipe with approximately output rates ranged from 800 to1000 kg/h. Some multi-screw designs were invented by combining two pairs of screws as one twin-screw. Smaller screw diameters provide a greater percentage of surface area to throughput, allowing a great heated energy to be input from the outside. Throttle designs were developed to provide better material compression in addition to heat and shear energy input. Six brand new parallel twin-screw extruders with diameters ranging from 50 to 160 mm were presented in 1976. The profile screws, rather than the breaker plate, were outfitted with a double flighted, closely intermeshing throttle, and the pelletizing and pipe screws were equipped with baffles.

Fabrication Of Basic Screw Extruder To Manufacture 3d Printers Filament[edit | edit source]

Summarize: Arvind et al.[2] fabricated a basic screw extruder for 3D printers' filament manufacturing, which is a vital part of 3D printing industry. Screw conveyor, drive train, feeding unit, heating system, casting, and extrusion head are essential components of any screw extruder. Our approach for choosing optimal properties of designed screw extruder was arranged based on an interview with industrial experts and a literature review. Then, the methodology was organized into five steps including data collection, selection of parameters, determining constraints, acquiring materials, and drawing. In the drawing step, Autodesk Inventor was used to assembling various components of the screw extruder as a whole design. Eventually, the final design of the extruder was fabricated and tested to ensure that the screw extruder can work properly to obtain plastic filament through the nozzle. To achieve good extrusion, expansion calculations of both mild steel and stainless steel during utilizing in the structure of the screw extruder were carried.

EN-8 (Euro Standard- 8) medium carbon steel is used to make the screw rod, which has a constant pitch of 40mm and a shifting center diameter of 20 to 32mm. The screw thread has an exterior diameter of 37.8mm. The helix angle is 18 and the thread width is 4 mm. A single rod of EN8 (Euro Standard 8) medium carbon steel is used to make the Screw Rod (Unalloyed Steel which is delivered by cold drawing). A cylindrical block of die steel was mounted on a lathe equipped with a four-jaw chuck. The die steel stock was aligned with the center of the lathe axis to ensure stock material concentricity before and throughout the machining process. The nozzle is constructed of brass and is attached to the extrusion head. The brass stock piece was obtained at a standard diameter of 25.4mm and then subjected to various machining procedures. The initial test, observations, and analysis were carried to examine the fabricated screw extruder, which the hopper getting heated as well as the lower temperature at nozzle region were recognized from these exact observations. The fabricated screw extruder was subjected to preliminary testing, observations, and analysis, which revealed that the hopper was being heated increasingly as well as the lower temperature at the nozzle region. So, the final modification was applied to the fabricated screw extruder to achieve a proper diameter of filaments.

ON THE DESIGN AND TECHNOLOGY OF CO-ROTATING TWIN SCREW EXTRUDERS[edit | edit source]

Summarize: Justino Netto and Silveira[3] proposed a methodical procedure technique for co-rotating twin screw extruder segments that provide valuable information to design an interchangeable printing head in Additive Manufacturing. Their results showed that the screws can rotate properly without fault and the material is transferred as predicted towards the die. Their method relies on designing a micro twin screw extruder intended to process small volumes of powder material (around 100 g) according to Pahl et al.,[4] which the design process includes per-dimensioning comes after the information gathering and conceptual design steps. After the assurances of the standard model configuration, the design's aspects include dimensions and tolerances, manufacturing procedures, and prices were finalized.

Note 1:To boost velocity steadily along the flow channel, fundamental aspects must be considered during die design for avoiding dead spots, therefore flow resistance parameter (Kp) was calculated by Equation 13 in their paper.

Note 2: Their findings showed that the developed design approach is appropriate for utilizing as a polymer compounding mini extruder and 3D print head.

Extrusion-based food printing for digitalized food design and nutrition control[edit | edit source]

Summarize: Sun et al.[5] reviewed the published works in the context of "food printing via extrusion techniques" to identify the problems and developments in this research area. The multi-axis configurations including Cartesian, Delta, Polar and Selective Compliant Assembly Robot Arm (Scara) are mainly used in the food printing procedure. The Cartesian structure has X, Y, and Z axes for left-to-right, front-to-back, and up-and-down movement. In the Delta, a circular print stage is installed, and the print head is placed over it by three triangle arms. A Polar food printer includes a rotating stage as well as a print head that can move up and down to cover the Z-axis and left and right to cover the X and Y axes tangentially. SCARA configuration consists of a robot arm that moves in the X-Y plane and an extra actuator that moves along the Z-Axis. Because of the higher proportion of printed nourishment component volume to printer size, shorter production time, and lower cost, a rising interest in designing printers with Delta or Polar structures is found. Although printing accuracy is important for consistent and repeatable fabrication, it is typically less demanding in food printing than in plastic printing or medical printing. In various designed food printers, three extrusion mechanisms including syringe, air pressure, and screw are used. The syringe-based extrusion unit consists of a syringe for storing feeding supplies and a step engine to power the extrusion operation. A pneumatic pump and an encapsulated food cartridge comprise an air pressure-driven extrusion device, with the pneumatic pump pushing the material within the encapsulated food cartridge out of the nozzle. Food materials are loaded into the cartridge and transferred to the nozzle by an auger screw in screw-based extrusion for continuous printing.

A comparative study between syringe-based and screw-based 3D food printers by computational simulation[edit | edit source]

Guo et al.[6] arranged computational research to study the difference between syringe-based and screw-based 3D food printers, which two mainly used Extrusion-based 3D in the food industry. the computational fluid dynamics (CFD) models were discussed in this study to assess and compare the fluid characteristics of two types of 3D printing. Also, an experimental 3D printing evaluation was performed to compare two different 3D food printers. The CFD simulations were carried out using the COMSOL Multiphysics computer software, which is a commercially available FEM-based computer program. The rotating machinery and laminar flow characteristics of the CFD Module were used in this study to address the fluid characteristic within the screw-based extrusion 3D printing and the syringe-based extrusion 3D printing hardware, respectively. Ink for 3D printing was made from mashed potatoes. Throughout the experiment, the temperature remained constant at 26 degrees Celsius. The fluid was considered to be a single-phase incompressible fluid with a laminar flow interface.

Note: A simulated model investigation revealed that the 3D food printer via screw had a complicated fluid characteristic, with a few backflows discovered at the gap between the walls and the screw flights in the extrusion tube. The syringe-based 3D food printer, on the other hand, looked to have more basic fluid characteristics that could be easily changed. Further, the experimental 3D printing suggested that screw-based 3D food printers were inappropriate for extruding viscous inks. The current study provides data for proper printing strategy selection, a theoretical foundation, and a specialized guide for advanced 3D printing research and modern printer design.

Axiomatic design and solution variants applied to a modular 3D printing head based in material extrusion[edit | edit source]

Summarize: Porpíglio et al.[7] designed an integrated procedure based on the solution variants method and axiomatic method that was applied to a modular 3D printing head. The solution variants method is determined by dedicating a positive number between 0 and 1 for any criteria according to its importance.By evaluating the transmission framework of a vertical twin screw head linked to a test 3D printer, the proposed method was tested in a real-world problem scenario. The case study 3D printer used powder as a raw material in small amounts (about 200 g)[8] for 4D printing experiments, containing compound and polymer mix definition, as well as filament generation. Their finding showed that the worm gear pair was the best option to drive the framework (higher value obtained from evaluation solution variation). Regarding the synchronization instrument to shafts (correlational twin screws), it was chosen by evaluation solution variation a framework with a synchronizing gear connecting the two extruders, which indicated the total weighted values increase to 7.55. The findings were supplemented by reangularity and semangularity lists, which yielded values of 0.838 and 0.500, respectively, confirming the choice of worm gear pair combined as a driving framework with a high degree of design flexibility.

Safety design and numerical simulation of twin screw extruder for energetic materials[edit | edit source]

Summarize: Ji et al.[9] created a twin screw extruder for energetic materials by providing safe conditions. In this work, an accurate numerical simulation based on the finite element approach was contained to predict the explosive moment of energetic materials in twin screw barrels with various pressure venting configurations. The thread elements' geometrical specifications are as follows: The screw's external diameter is 50.4 mm, its center distance is 40.8 mm, its outer diameter and barrel are separated by a 0.5 mm gap, and its pitches are 50 mm and 75 mm, respectively. Also, the Bird-Carreau model was used to characterize the runner's flow properties.[10] A specific barrel was designed to resist against explosive waves, which two pressure relief holes were considered in the barrel model. Their results showed that the screw flight's top and the intermeshing zone have largest pressure and shear rate during the manufacturing of energetic materials by twin screw extruders. So, explosion mishaps and detonation are most likely to happen in these points. The pressure within the horizontal split barrel is visibly lower than a regular barrel layout. It is shown that the secondary pressure vanishes and the deformation of the barrel is greatly reduced.

Structure Analysis and Optimization Design of FDM Wire Extruder Screw[edit | edit source]

Summarize: Li et al.[11] proposed an optimized design of fused deposition modeling (FDM) Wire extruder screw, which is one of the most broadly used 3D printing technologies in the world. In this research, ANSYS finite element software was applied to predict the flow's parameters in the extruder screw. The orthogonal test method was used for investigating the effects of screw pitch, screw depth, screw groove width, screw edge width, and length of the metering section on velocity field, pressure field, temperature field, and shear rate. Also, SolidWorks software was used to generate the screw 3D model and ABS material with specific properties was used during the simulation. Finally, the effectiveness of the suggested model was examined for each parameter using Minitab version 17 software. After determining the ideal of factors, the optimized screw was examined and validated. Their results showed that the proposed wire extruder can work efficiency when the screw pitch, the depth of screw groove, the width of screw edge and the length of measuring section are 15mm, 1.3mm, 1.5mm and 85mm, respectively. The optimized screw can enhance the melting efficiency of the ABS material.

DEM analysis of residence time distribution during twin screw granulation[edit | edit source]

Summarize: Zheng et al.[12] studied the twin screw granulation (TSG) process using a discrete element method (DEM). In this study, a graphics processor unit (GPU) foundation was used for developing the DEM to obtain both macroscopic and microscopic insights. The translational and rotational movements of each particle in DEM are determined by Newton's second law. Screw radius (Rs), center line distance (Cl), gap between two screws (s), gap between inner barrel and screw (b), and the number of parallel channels (e) are the primary geometric characteristics. The two screws are orthogonal. Initially, the twin screw granulator geometries were generated using computer-aided design (CAD) software and saved as a standard stereolithography (STL) format file for further processing. Then, the STL file was loaded into BlazeDEM-GPU, where the DEM model for the twin screw granulator was created. For evaluation of system performance, the residence time distribution (RTD) was determined by screw speed, screw configuration, and material parameters. The residence time distribution function (E-curves) exhibited a reduced spread for bigger particle size and higher screw speed, meaning that the particles had considerably residence time in the twin screw granulator. Finally, their findings showed that DEM can present a reliable basis for modeling twin screw granulations. However, the effects of screw arrangement and formulation parameters (such as particle shape and liquid binder addition) on twin screw granulation behavior must be examined in future works.

Optimizing screw profiles for twin-screw food extrusion processing through genetic algorithms and neural networks[edit | edit source]

Summarize: Kowalski et al.[13] developed a novel method for optimizing the screw profile design process using a combination of a genetic algorithm model and a neural network fitness function. Specific characters of screw profiles for various target products were considered in necessary conditions. Versatile quantities were predicted for optimal twin-screw food extrusion performance including pressure, motor torque, specific mechanical energy (SME), expansion ratio (ER), water absorption (WAI), and water solubility (WSI). In this study, hard red spring waxy wheat flour (var. Sagitario) was used, which is obtained from the USDA Western Wheat Quality Laboratory (Pullman, WA, USA). The flour contained 14.1 percent of protein (percent dry basis), which was hydrated at 4 ℃ in a mixer to reach specified moisture content. Colorimetric examination with an iodine solution was used to verify the lack of amylose. The extrusion process was carried out with a 20 mm diameter co-rotating twin-screw extruder (Model TSE 20/40, CW Brabender Instruments Inc., South Hackensack, NJ, USA). The extruder was conducted with a 20:1 L/D ratio and four separate temperature regulated zones. Both a genetic algorithm model and a neural network model were performed using MATLAB (R2015b, MathWorks, Inc., Natick, MA, USA). For pressure, motor torque, and SME process responses, Neural network models demonstrated high R2 values (>0.979), but ER (0.935), WSI (0.900), and WAI product responses (0.847) demonstrated significantly lower R2 values. Five different target products were generated in five independent trials using the genetic algorithm model. Among trials 1, 3, 4, and 5 with two standard deviations, trial two had a little higher expansion than predicted. For trials 1, 2, and 4, the water absorption index was within two standard deviations. For trials 1, 3, 4, and 5, the water solubility index was within two standard deviations. The predicted variance was especially significant in WAI, which has a broader range of variability. Finally, their findings showed that the proposed method has sufficient efficiency to predict optimal characteristics of screw profile design to provide a better extrusion process.

Design And Fabrication Of Extrusion Machine For Recycling Plastics[edit | edit source]

Summarize: Kumar et al.[14]built an extrusion system for producing filament from recyclable plastics, which is a vital part of 3D printer designing. In this work, an expulsion machine was constructed to generate 3D printing fiber from PET bottle pellets. The final design was a low-cost, high-performance machine that shreds, dissolves, and mixes polyethylene terephthalate plastic water bottles after expelling them as homogenous fiber. The main procedure of the designed extrusion system contains a screw that transfers recyclable plastic pellets from a holder through a warming spot in a metal line where the plastic is liquefied by high thermal temperature. Then, the liquified plastic pellets are moved into the screw from the holder to compress through a spout toward the end of the line to frame a fiber. The extrusion process has five individual stages including installing extruder nozzle, material temperature fixing, feed hopper, guide filament, and measuring the diameter of filament, in which the temperature can change to achieve distinct sizes of filament. The design process was performed in seven phases including barrel, hopper, nozzle, screw rod, shredder blade, shredder casting, and extrusion assembly. Their results showed that optimum outcome can be achieved by fixing the temperature ranges between 230-250°C and a high-efficiency rate can be achieved by decreasing the heat conduction. With a higher separation between the container and the warm zone, a larger volume of plastics may be included, allowing the extruder to discharge more fiber without the risk of blocking the delta of the warming line.

Structure design for improving the characteristic attributes of extruded plant-based meat analogues[edit | edit source]

Summarize: Sun et al.[15] developed a structure design to improve the quality of plant-based meat analogues similar to actual animal meats. In this study, high moisture extrusion technology was used to evaluate formulations and optimize extrusion conditions, and the link between structure and formulation/processing was explained. The significance of important structural components such as proteins, polysaccharides, and their mixes in the production of fibrous structures in meat analogues was investigated. Then, the influence of barrel temperature, cooling die design, and feed moisture level in attaining meat analogue quality was explored. Their findings demonstrated that high moisture extrusion is a realistic and cost-effective processing method for producing plant-based meat analogues. Furthermore, the required qualities of the end product may be accomplished by regulating process factors such as barrel temperature and feed moisture content.

On-Line Optical Monitoring of the Mixing Performance in Co-Rotating Twin-Screw Extruders[edit | edit source]

Summarize: Bernardo et al. [16] suggested an On-Line optical monitoring method for evaluating the global mixing performance of co-rotating twin-screw extruders by considering various geometries. The proposed technology relies on light scattering and retardation caused by dispersed phase particles, which can be used to obtain information on particle number (as turbidity) and shape (as form birefringence). Then, at various axial points along three separate kneading blocks and under a variety of screw speeds, residence time distribution curves (RTD) were formed. The parameters K (a constant in the pulse curve linked to the area under an RTD curve) and the variance of the RTD curves were utilized to depict dispersive and distributive mixing indices. It is demonstrated that K is an accurate indicator of dispersive mixing, whereas variance may be utilized to evaluate distributive mixing. The results of the experiments indicated that these mixing indices are sensitive to changes in processing circumstances and reflect the predicted behavior of each kneading block geometry.

Key technological advances of extrusion processing[edit | edit source]

Summarize: Emin[17] studied the state of art technological developments of extrusion processing that have a valuable place in food industries due to its flexibility for utilizing various raw materials for producing adaptable food products. The studies on this process are mainly divided into two essential sections including screw and die, which are concerned with extruded raw material and giving the desired shape and texture to the products. After these two sections, a product will be ready to eat by customers. For ensuring the quality of the designed products, some analyses include reaction properties and rheological properties were conducted. In the reaction properties analysis, not only the molecular interactions are considered but also some factors including temperature, time, shear stress, components, mixing ratio, and water content is considered. In the rheological properties, blending properties, thermal and mechanical stress profile in the screw section, or expansion and texturizing in the die section are examined. Analysis of processing conditions is another critical step that includes thermal stress profile analysis, and thermomechanical stress profile and mixing characteristics analysis. For the first analysis (thermal stress profile), it is very essential to gather some information regarding the temperature of the material and its residence time. For the later one (thermomechanical stress profile and mixing characteristics), numerical analysis mainly finite element method (FEM) using FEM code ANSYS POLFLOW is performed to obtain essential information about thermomechanical stress profile and mixing characteristics. The gathered information then can be used to adjust the process to precisely perform a process to obtain the desired product or to achieve products in different preferred scales.

Design[edit | edit source]

Design 1[edit | edit source]

Summarize: This design procedure was used by Sobowale et al.[18][19] to fabricate a twin screw extruder.The extruder was designed to resolve all the problems mentioned in the construction of a twin screw extruder conducted by Senanayake and Clarke[20] and Yamsaengsung and Noomuang.[21] In this work, the performance of the designed extruder was investigated using various instruments including cocoyam flour, varying feed moisture content (FMC), and screw speed (SS). Various factors such as expansion ratio, residence time (RT), throughput, and functional efficiency were analyzed to ensure that all parts of the extruder are suitably assembled and work properly with high efficiency. The constructed extruder operated admirably, with products expanding quite well. Except for the discoloration of the cocoyam extrudate at increased temperatures, which resulted in an undesirable product, there were no serious issues during the operation. This finally influenced the barrel temperature and FMC used, and it is suggested that cold extrusion is more appropriate for the cocoyam extrudate. By inserting a replacement die unit of various forms into the machine, tests on the equipment proved its capabilities as a multifunctional extruding machine generating numerous expelled items of diverse shapes and sizes.

Calculations[edit | edit source]

Design calculations were performed based on the work of Senanayake and Clarke,[20] Harold et al.,[22] Khurmi and Gupta,[23] Singh and Heldman,[24] and Sobowale et al. works.[25][26][19] The various parameters of a twin screw extruder designed in are listed in Table I. Essential values were defined and other values with less importance were obtained during the design calculations. These parameters are critical to satisfying the goals of designing a proper twin screw extruder in terms of commercial, mass production, and precise extruded products. So, defining parameter values and the relationship between them must be carefully considered during the twin screw extruder design.

| Parameter | Symbol | Unit | Assumptions | Number of Formula |

| Length of barrel | Lb | mm | - | (1) |

| Screw length | L | mm | 1898, L/D ratio is 25/1 | (1) |

| Screw diameter | D | mm | 65, L/D ratio is 25/1 | (1) |

| Beam height | Ymax | mm | - | (2) |

| Initial pitch circle diameter | Po | mm | - | (2) |

| Beam thickness | b | mm | - | (2) |

| Beam face length | I | mm | - | (2) |

| Total power consumption | Pt | kW | - | (3) |

| Portion of the power consumption for viscous dissipation | Ps | kW | - | (3) |

| Speed diameter | Vd | mm | - | (3) |

| Pressure difference | ΔP | N mm-2 | - | (3) |

| Screw power

number |

Np | rpm | - | (4) |

| Extrudate density | ρ | kg/m3 | - | (4) |

| Screw speed | N | rpm | - | (4) |

| Speed ratio | Nr | rpm | - | (5) |

| Diameter of the driven pulley | D2 | mm | 73.5 | (5) |

| Diameter of

the driving pulley |

D1 | mm | - | (5) |

| Speed of the driving pulley | N1 | rpm | - | (6) |

| Speed of the driven pulley | N2 | rpm | - | (6) |

| Barrel length | Bl | mm | - | (7) |

| Flight width | ε | mm | 5.6 | (8) |

| Radial flight clearance | δf | mm | 0.2 | (9) |

| Inside diameter

of the extruder barrel |

Db | mm | 65.2 | (15) |

| Helix angle at the

root of the screw |

θs | degree | - | (10) |

| Helix angle at the root of the bolt | θb | degree | - | (10) |

| Channel width at the

root of the screw |

Ws | mm | - | (11) |

| Channel width at the

root of the bolt |

Wb | mm | - | (11) |

| Weight of the pulley | Wp | N | 14.715 | (12) |

| Mass of the pulley | Mp | kg | 1.501 | (12) |

| Volume of the hopper | V | m3 | 4.125 × 103 | (13) |

| Change in shaft radius | Δr | mm | - | (13) |

| Height of the shaft | h | mm | - | (13) |

| Diameter of the shaft | Ds | mm | 24 | (14) |

| Permissible shear stress of the shaft (torque) | T | Nm | 4.95 | (14) |

| Mass flow rate | m | kg/hr | 50 | (15) |

| Channel depth of metering | Hm | mm | 2.72 | (15) |

| Specific gravity | G | no unit | - | (15) |

| Dynamic bearing capacity of thrust Bearing | Creq | kN | 15.14 | (16) |

| Factor for sense of rotation | fd | no unit | - | (16) |

| Thrust pressure from the extruder | Fax | kN | 15.14 | (16) |

| Bearing life duration | Lf | hr | - | (16) |

Design 2[edit | edit source]

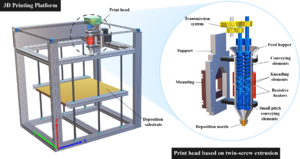

Summarize: Justino Netto and Silveira[27] designed a 3D Printer head (Fig. 2) by applying twin-screw extrusion concept, in which both approaches of in-process multi material mixing and direct deposition of the product simultaneously were organized for the proper creation of 3D objects. Their methodology were established based on Kohlgrüber book on designing Co-rotating twin-screw extruder.[28] To evaluate the correctness of the formalized procedure, a real-scale print head of ABS was produced by using a 3D printer. Prototyping experiment revealed that manufacturing small screw elements is challenging albeit it is feasible. Also, their findings revealed that alternative procedures must be arranged for more compacting the transmission system. Moreover, the utilized framework might be used in other projects that deal with small-scale designing and provide helpful a systematic approach to clearly define the influence factors on designing 3D print heads.

Table II showed the parameters of designing a three-dimensional print head based on twin-screw extrusion that was proposed by Netto and Silveira.[27] Similar works in the literature ignore reporting this valuable information. In this work, a systematic approach to aspects of the designing procedure was reported precisely to provide a complete guideline for future works. Moreover, the analytical models of this work are very useful to adapt the decision-making process in other small-scale extruders in similar works.

| Parameter | Symbol | Unit | Assumptions | Number of Formula |

| External diameter | DE | mm | 12.0 | (1) |

| Centerline distance | A | mm | 10.2 | (1) |

| Number of threads | Z | 2 | (1) | |

| The screw pitch | P | mm | 18, 12, 6 | (6) |

| Clearance between the screws | s | mm | 0.2 | - |

| Flank angle of the offset profile | FW1 | deg | 70.44, 69.31, 66.89 | - |

| Flank angle of the fully wiped profile | FW0 | deg | 63.6 | - |

| Tip angle of the offset profile | KW1 | deg | 12.69, 14.95, 19.78 | - |

| Tip angle of the fully wiped profile | KW0 | deg | 26.4 | - |

| The reduced external

diameter |

DA | mm | 11.8 | (3) |

| The reduced internal

diameter |

DK | mm | 8.2 | - |

| The internal diameter | DI | mm | 8.4 | - |

| The intended low rotation speed of the screws | N | rpm | 10 | (3) |

| The minimal diameter

of the shafts |

ds | mm | 5.5 | (2) |

| The stipulated driving torque | MD | N.m | 10 | (2) |

| The permissible stress | τadm | MPa | 689.6 | (2) |

| Clearance | σ | mm | 0.2 | (3) |

| The length of the screw | L | mm | 120 | (5) |

| The free cross section area between the screws and the barrel | Afree | mm2 | 74.4 | (6) |

| Orifice diameter | d0 | mm | 2.38 | (7) |

| The wall shear rate | s-1 | 43.5 | (7) | |

| The length of the die | Ldie | mm | 12.5 | (8) |

| Dimensionless parameter for flow resistance | Kp | No unit | 3.8 × 104 | (8) |

| The circumscribed diameter of the hexagonal shafts | ds | mm | 5.5 | (10) |

| The effective length of the shafts | Leff | mm | 240 | (10) |

| The compressive load | Fapp | mm | 155 | - |

| Pressure drop at the die | Δp | MPa | 1.37 | (8) |

References[edit | edit source]

- ↑ Schneider, Hans-Peter (2005). "The historical development of the counter-rotating twin-screw extruder". Kunstoffe Plast. Eur 1: 1–6.

- ↑ Christiyan, Jaya (2016-09-01). "Fabrication Of Basic Screw Extruder To Manufacture 3d Printers Filament". International Journal of Research in Engineering and Technology 5.

- ↑ Silveira, Zilda de Castro; Justino Netto, Joaquim Manoel (2017). "ON THE DESIGN AND TECHNOLOGY OF CO-ROTATING TWIN SCREW EXTRUDERS". Anais do IX Congresso Brasileiro de Engenharia de Fabricação. Congresso Brasileiro de Engenharia de Fabricação. ABCM. doi:10.26678/ABCM.COBEF2017.COF2017-0017. Retrieved 2022-01-11.

- ↑ Pahl, Gerhard; Beitz, Wolfgang; Feldhusen, Jörg; Grote, Karl-Heinrich (2007). "Product Development Process". In Gerhard Pahl, Wolfgang Beitz, Jörg Feldhusen, Karl-Heinrich Grote (eds.). Engineering Design: A Systematic Approach. London: Springer. pp. 125–143. ISBN 978-1-84628-319-2. Retrieved 2022-01-11.

- ↑ Sun, Jie; Zhou, Weibiao; Yan, Liangkun; Huang, Dejian; Lin, Lien-ya (2018-03-01). "Extrusion-based food printing for digitalized food design and nutrition control". Journal of Food Engineering. 3D Printed Food – Design and Technology 220: 1–11. doi:10.1016/j.jfoodeng.2017.02.028. ISSN 0260-8774. Retrieved 2022-01-11.

- ↑ Guo, Chao-Fan; Zhang, Min; Bhandari, Bhesh (2019-07-01). "A comparative study between syringe-based and screw-based 3D food printers by computational simulation". Computers and Electronics in Agriculture 162: 397–404. doi:10.1016/j.compag.2019.04.032. ISSN 0168-1699. Retrieved 2022-01-11.

- ↑ I, Porpíglio; Rk, Scalice; Zc, Silveira (2019-01-01). "Axiomatic design and solution variants applied to a modular 3D printing head based in material extrusion". 29th CIRP Design Conference 2019, 08-10 May 2019, Póvoa de Varzim, Portgal 84: 143–148. doi:10.1016/j.procir.2019.04.319. ISSN 2212-8271.

- ↑ Wang, Haoqi; Zhang, Xu; Tang, Chengtong; Thomson, Vincent (2018-06-01). "A semantic model for axiomatic systems design". Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 232 (12): 2159–2184. doi:10.1177/0954406217718858. ISSN 0954-4062. Retrieved 2022-07-11.

- ↑ Ji, Dandan; Xiao, Yong; Huang, Qiuan; Shi, Huifang (2020-03). "Safety design and numerical simulation of twin screw extruder for energetic materials". Journal of Physics: Conference Series 1507 (2): 022027. doi:10.1088/1742-6596/1507/2/022027. ISSN 1742-6596. Retrieved 2022-07-21.

- ↑ Dus, SJ; Kokini, JL (1990). "Prediction of the nonlinear viscoelastic properties of a hard wheat flour dough using the Bird–Carreau constitutive model". Journal of Rheology 34 (7): 1069–1084. ISSN 0148-6055.

- ↑ Li, Bin; Zhang, Peng; Gu, Hai; Jiang, Jie; Sun, Jianhua; Xu, Yuanyuan; Zhang, Jie (2021-03). "Structure Analysis and Optimization Design of FDM Wire Extruder Screw". Journal of Physics: Conference Series 1802 (2): 022003. doi:10.1088/1742-6596/1802/2/022003. ISSN 1742-6596. Retrieved 2022-07-21.

- ↑ Zheng, Chao; Zhang, Ling; Govender, Nicolin; Wu, Chuan-Yu (2021-01-02). "DEM analysis of residence time distribution during twin screw granulation". Powder Technology 377: 924–938. doi:10.1016/j.powtec.2020.09.049. ISSN 0032-5910. Retrieved 2022-07-21.

- ↑ Kowalski, Ryan J.; Pietrysiak, Ewa; Ganjyal, Girish M. (2021-08-01). "Optimizing screw profiles for twin-screw food extrusion processing through genetic algorithms and neural networks". Journal of Food Engineering 303: 110589. doi:10.1016/j.jfoodeng.2021.110589. ISSN 0260-8774. Retrieved 2022-07-21.

- ↑ Kumar, Sagar; Sooraj, R.; Kumar, M. V. Vinod (2021-02). "Design And Fabrication Of Extrusion Machine For Recycling Plastics". IOP Conference Series: Materials Science and Engineering 1065 (1): 012014. doi:10.1088/1757-899X/1065/1/012014. ISSN 1757-899X. Retrieved 2022-01-11.

- ↑ Sun, Cuixia; Fu, Jialing; Chang, Yuyang; Li, Saiya; Fang, Yapeng (2022-06-01). "Structure Design for Improving the Characteristic Attributes of Extruded Plant-Based Meat Analogues". Food Biophysics 17 (2): 137–149. doi:10.1007/s11483-021-09692-w. ISSN 1557-1866. Retrieved 2022-07-29.

- ↑ Bernardo, Felipe; Covas, José A.; Canevarolo, Sebastião V. (2022-01). "On-Line Optical Monitoring of the Mixing Performance in Co-Rotating Twin-Screw Extruders". Polymers 14 (6): 1152. doi:10.3390/polym14061152. ISSN 2073-4360. Retrieved 2022-07-29.

- ↑ Emin, M. Azad (2022-01-01). "7 - Key technological advances of extrusion processing". In Pablo Juliano, Roman Buckow, Minh H. Nguyen, Kai Knoerzer, Jay Sellahewa (eds.). Food Engineering Innovations Across the Food Supply Chain. Academic Press. pp. 131–148. ISBN 978-0-12-821292-9. Retrieved 2022-01-11.

- ↑ 18.0 18.1 Sobowale, S. S.; Adebo, O.; Adebiyi, J. A. (2018). "Development of a twin screw extruder". Retrieved 2022-01-09.

- ↑ 19.0 19.1 19.2 Sobowale, Sunday Samuel (2017). "Design, construction and performance evaluation of a twin screw extruder". Agricultural Engineering International: CIGR Journal 19 (4): 181–186. ISSN 1682-1130.

- ↑ 20.0 20.1 Senanayake, S. A. M. A. N. S; Clarke, B (1999-05-01). "A simplified twin screw co-rotating food extruder: design, fabrication and testing". Journal of Food Engineering 40 (1): 129–137. doi:10.1016/S0260-8774(99)00049-7. ISSN 0260-8774. Retrieved 2022-01-09.

- ↑ Yamsaengsung, Ram; Noomuang, Chumporn (2010). Finite Element Modeling for the Design of a Single-Screw Extruder for Starch-Based Snack Products. pp. 5.

- ↑ Jr, Harold F. Giles; III, Eldridge M. Mount; Jr, John R. Wagner (2004-12-31). Extrusion: The Definitive Processing Guide and Handbook. William Andrew. ISBN 978-0-8155-1711-5.

- ↑ Gupta, RS Khurmi (2005). A Textbook of Machine Design. S. Chand Publishing. ISBN 978-81-219-2537-2.

- ↑ Singh, R. Paul; Heldman, Dennis R. (2001-06-29). Introduction to Food Engineering. Gulf Professional Publishing. ISBN 978-0-08-057449-3.

- ↑ "Design and Performance Evaluation of a Melon Sheller - Sobowale - 2016 - Journal of Food Process Engineering - Wiley Online Library". Retrieved 2022-01-09.

- ↑ Sobowale, Sunday Samuel; Adebiyi, Janet Adeyinka; Adebo, Oluwafemi Ayodeji (2017). "Design, construction, and performance evaluation of a gari roaster". Journal of Food Process Engineering 40 (3): –12493. doi:10.1111/jfpe.12493. ISSN 1745-4530. Retrieved 2022-01-09.

- ↑ 27.0 27.1 27.2 Justino Netto, Joaquim M; Silveira, Zilda de C (2018). "Design of an innovative three-dimensional print head based on twin-screw extrusion". Journal of Mechanical Design 140 (12): 125002. ISSN 1050-0472.

- ↑ Kohlgrüber, Klemens (2012). Co-rotating twin-screw extruder. Carl Hanser Verlag GmbH Co KG. ISBN 3-446-43341-4.