|

|

| Line 12: |

Line 12: |

|

| |

|

| }} | | }} |

| This page describes my custom modifications to the MOST-Delta printer constructed at Michigan Technological University as part of the graduate level final project for [http://www.appropedia.org/MY4777 MY4777/MY5777/EE4777/EE5777 Open-source 3-D printing] . During initial construction of the printer I was immediately planning modifications to help with better print quality and to allow for various printed materials. Instead of a single modification I made multiple modifications to build my personalized printer to my specifications. The final goal of the semester long project was to print with ABS on a heated bed. | | This project is setting for RepRap Auto Calibration. Since we need to do a lot of adjustment when we set up the RepRap Printer, the calibration part cost much time and hardly be accuracy. So we build the circuit and program the software to make it automatically, save time, free your hands. |

|

| |

|

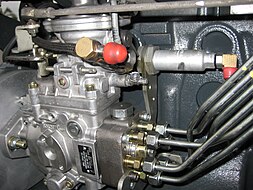

| In order to complete this task multiple modifications needed to occur. The first and most difficult modification was in the power supply. When using a heated bed there is an extra 10 Amp draw that needs to be accounted for when powering the printer. The cheapest route to increase the power to a minimum of 15 Amps was to modify a 203W 16.5 Amp XBOX 360 Power Supply. This unit was free since I had a broken XBOX in the closet suffering from the "Red Ring of Death." Once the power supply requirements were met the RepRap MK2b heated bed was wired and installed. To attain a flat and level print surface a borosilicate glass panel was obtained. This material can stand up to multiple heating and cooling cycles without shattering. A GeeeTech 100k termistor was implemented to control the bed temp. After all of the modifications were completed the firmware was adjusted to allow for the use of a heated bed, and new tie rod lengths from the carbon shafts.

| | Here is what we need to build this project: |

|

| |

|

| Listed below are the modifications that were completed this semester to allow for the use of ABS material:

| | *control board: MSP430 Launchpad (3.3v only) |

| | | *blue tooth-serial port : HC06 |

| *203W Modified XBOX Power Supply | | *touch sensor: TTP223B |

| *RepRap PCB MK2b heated bed | |

| *Borosilicate Glass Print Surface

| |

| *Carbon Tie Rods

| |

| *Aluminum Pulleys

| |

| *ZeniKentics Spool mount

| |

|

| |

|

| =Bill of Materials= | | =Bill of Materials= |

Revision as of 18:37, 11 December 2014

Introduction

This project is setting for RepRap Auto Calibration. Since we need to do a lot of adjustment when we set up the RepRap Printer, the calibration part cost much time and hardly be accuracy. So we build the circuit and program the software to make it automatically, save time, free your hands.

Here is what we need to build this project:

- control board: MSP430 Launchpad (3.3v only)

- blue tooth-serial port : HC06

- touch sensor: TTP223B

Bill of Materials

Source Files/ Links

Tools

- Soldering Iron

- Hobby Knife

- Drill (w/ bits and drive set)

- Allen Wrench Set

- Dremel Tool

- Hammer

- Engineering Prowess

Consumables

- PLA

- Shrink Tube

- Solder

- JB Weld Epoxy

Cookies help us deliver our services. By using our services, you agree to our use of cookies.