This is a review of basin solar stills, they have been deployed by several groups and studied see Solar stills for more information.

Introduction[edit | edit source]

Clean drinking water is a basic human need. Many people, especially in developing countries, do not have access to clean drinking water. Water that is dirty or salty is undrinkable, and untreated water that looks clean is likely to have bacteria and organisms that cause sickness and disease. A solar still is a device that produces clean, drinkable water from dirty water using the energy from the sun. This inexpensive device can easily be built using local materials.

This article focuses on the single sloped basin type of solar still. There are vast amounts of research on this type of solar still and so the purpose of this article is to provide an accessible, open source literature review with a summary of the research, without overlapping too much with the informative Appropedia article Understanding Solar Stills. Additionally, this article reviews the idea of using the input water to cool the glass cover as a way to increase the productivity of the still.

Operating Principle[edit | edit source]

Salty or dirty water in an airtight container is heated by the sun, causing it to evaporate. The water then condenses on the clear container covering, which is slanted to allow the fresh water to drain into a collection unit. The pure water evaporates and the impurities do not, distilling the water and making it safe to drink.

For more information go to:

Understanding solar stills "Operating Principles" section

Types of Solar Stills[edit | edit source]

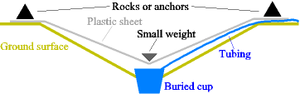

There are several different types of solar stills. The most basic is the "pit" type, which is most appropriate for emergency survival situations because it has a very low productivity. See Figure 1 for a diagram of the pit still.

The "cone" type still looks like an inverted pit-type still. The Watercone is a product on the market.

The basin, or box still is the most complex type. There are many different variations, but the two main categories of basin stills are single and double sloped. Figure 2 shows a picture of a single sloped basin still and Figure 3 shows the double sloped still.

The double sloped basin still is a similar but has two sloped pieces of glass rather than one.

The benefits of the basin solar still are that it can produce several liters of water per square meter of still, per day. With an upfront capital cost to invest in good materials, this still can be built sturdy enough to operate faithfully with an efficiency of 30-60% for as long as 20 years.[1]

Design Principles of a Single-Slope Basin Solar Still[edit | edit source]

Design requirements:

- Distills water so it is drinkable

- Has a maximum yield of distilled water

- Easy to build and repair (minimize amount of maintenance needed)

- Not too sensitive to minor details

- Reliable

- Easy to clean

- Uses common, natural building materials

- Unnatural materials must be easily transported

- Inexpensive

- Produces minimal waste at end of life

- Can withstand harsh weather conditions and degradation by heat and UV

- Easy to use (don't need to disassemble to put the dirty water in and get the fresh water out)

Problems to overcome:

- Dust on the transparent cover

- Algae and scaling on the black surface

- If it is flushed daily this may help

- Dry-out ruins the still because the white salt dries to the black surface, the glass heats up and gets brittle, as well as the glass surface changes so that the condensate forms as droplets instead of a film, which decreases performance[2]

- If the still will dry out, a hatch should be opened, but people often won't do this

Design restrictions:

- Glass can be no bigger than 1 m in length or else it will break easily[2]

- Glass should be at least 4 mm thick[2]

- A concrete slab larger than 5 m will crack[2]

- Glass angle at 15 deg is optimal[2]

- The angle should try match the angle of the sun in order to maximize solar exposure of the basin, but still allow complete run off.

Engineering Principles[edit | edit source]

It is important for solar still builders and operators to know how the still operates so they can apply that knowledge in problem solving and troubleshooting.

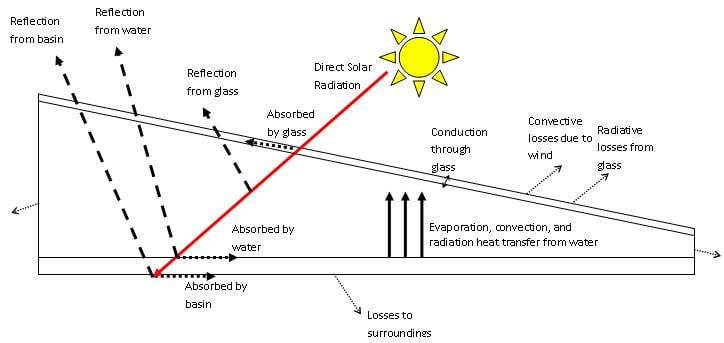

The most important factor that affects level of production of the solar still is the amount of solar radiation on the glass cover, called irradiance. Not all of the solar energy that contacts the glass will actually be used for evaporation of the water in the basin because it gets reflected and absorbed by anything it passes through. Figure 4 is an energy flow diagram that shows that part of the sunlight is reflected and absorbed by the glass, the water, and the basin surface. If the still is not perfectly sealed and insulated there will be heat losses to the surroundings.

There are some common assumptions that are made when performing a theoretical thermal analysis on a solar still:

- The area of the glass cover is the same as the area of the basin[3]

- There is no temperature gradient across the depth of the water or the glass[4]

- The change in density and specific heat of the water with change in temperature is negligible[4]

- The heat capacity of the glass is negligible[4]

- The still is airtight[4]The energy that the water absorbs contributes to the temperature rise of the water, which leads to evaporation. Evaporation is a process that occurs when the water molecules on the surface of the water obtain enough kinetic energy to change from the liquid to vapour state. The evaporated molecules add to the water vapour between the glass and the water. Because the glass cover has a lower heat capacity than water, and it is exposed to the outside air, it will not heat up as much as the water will. This difference in temperature affects the temperature of the air/water vapour that is inside the still between the glass and the water, which creates natural convection. A higher temperature difference encourages more convection.[5]The warm water vapour will tend to rise towards the cooler glass cover. When the water vapour comes in contact with the glass, it will condense because the water molecules will lose the kinetic energy needed to be in the vapour state. Since the glass is angled, gravity will cause the condensed water to flow down towards the collection trough.

Equations[edit | edit source]

The general equation to describe heat transfer is an energy balance, which basically says the sum of the heat in must equal the sum of the heat out. This is based on the law of the conservation of energy which says that heat can be neither created or destroyed. This energy balance can be written for the entire still or on a smaller scale for the heat transfer of the glass cover or the water in the basin.

The "q's" can represent heat transfer by convection, conduction, or radiation.[6]

Convection[edit | edit source]

In general, the rate of convective heat transfer[7] is given by:

Where

- q = heat transfer in

- h = heat transfer coefficient in

- = temperature of the surface in °C

- = temperature of the fluid at the bulk temperature (far from the surface or, in the case of condensation, the saturation temperature) in °C

Conduction[edit | edit source]

In general, the rate of conductive heat transfer[8] is given by:

Where

- q = heat transfer in . The direction of heat transfer is from hot to cold.

- k = thermal conductivity in

- = temperature difference of the surface in K

- = thickness of the surface or distance traveled by q, in m

Radiation[edit | edit source]

In general, the rate of radiative heat transfer[9] (from a blackbody) is given by:

Where

- q = heat transfer in .

- = The Stefan-Boltzmann Constant =

- T = temperature of the body in K

Optimization[edit | edit source]

Increasing the temperature difference between the water in the basin and the glass cover is the main focus when trying to improve the rate of condensation, and therefore increase the productivity of the still. This can be done by either increasing the temperature of the water or decreasing the temperature of the glass. Many researchers have experimented with different methods of accomplishing this.

To increase the temperature of the water:

- preheating the feed water

- add black dye to the water to make it more absorbent[10]

- adding a floating perforated plate to the basin[11]

- have good insulation under and around the still

- decrease the heat capacity of the water

- by decreasing the water level

- using a wick or porous materials[12][13][14]

- using reflectors inside and outside the still to concentrate more solar energy

To decrease the temperature of the glass:

- run cooling water over the outside surface of the glass

Other parameters that have been researched include glass tilt angle and thickess, orientation, wind velocity, ambient temperature, initial brine temperature, brine water depth, and dimensions of the still.

Improving Productivity Using Cooling Water over the Glass Cover[edit | edit source]

Research has been conducted on the improvement of solar still productivity using cooling water over the glass cover. This idea is very simple because it only involves modifying the way the feed water is introduced to the still. This can be done by simply raising the feed water container to the level of the highest part of the still and directing the flow over the glass. Dutt et al. used a regulating valve to control the flow rate through a perforated pipe along the highest end of the glass cover.[4]The perforations in the pipe created a smooth, steady film of water. Lawrence et al. used a similar setup.[15]

Not only does the water film cool the glass, which increases the rate of condensation, it also slightly preheats the feed water, continuously cleans the glass surface, insulates the still by reducing convection and radiation losses from the glass, and surprisingly, lets more light in. The way the water lets more solar radiation into the still is by the lower index of refraction, which is 1.33 for water and 1.52 for glass. This reduces the proportion of energy absorbed into the glass.[3]Common assumptions are made in the literature about theoretical analysis of a solar still with cooling water.

Assumptions:

- There is no temperature gradient over the depth of the cooling water film[4]

- The absorptivity and heat capacity of the cooling water is negligible[4]

- Uniform flow rate[14]

- Laminar flow[3]

Literature Review[edit | edit source]

Dhiman and Tiwari performed an analytical analysis of water flow over the glass cover of a solar still and found that this modification increased output by 10%. The flow reduced both the glass temperature and the temperature of the brine, but still produced a larger temperature difference because the glass temperature was decreased much more than the water temperature.[13]Lawrence et al. obtained numerical and experimental results showing a 5% increase in efficiency with water flowing over glass. Water flow velocity of 1.5 m/s gave the greatest still efficiency, but the effect of flow velocity on efficiency is only a matter of a few percent.[15]Abu-Hijleh et al. showed, numerically, that cooling water can increase efficiency by 20% with the right conditions, but can decrease efficiency with the wrong conditions. The cooling water cancels effect of wind speed and the amount of cooling water that evaporates to atmosphere is negligible. They also showed that too high of a water flow rate takes out too much heat, greatly decreasing the temperature of the water in the basin.[3]

Experiment[edit | edit source]

I performed a simple experiment to see the effect the flowing water has on the amount of sunlight that gets through the glass.

Construction[edit | edit source]

Materials[edit | edit source]

Materials are very important in the construction of solar stills because they must be able to withstand harsh weather conditions, they cannot degrade when in contact with water and hot sun, and they must not leave a bad taste in the distilled water. Very few materials work well for the individual components of the still, but based on trial and error good solutions have been discovered.

Understanding Solar Stills: Materials has a complete report on materials used in the construction of solar stills, including information based on experience.

Tools[edit | edit source]

Most of the tools needed for the construction of a solar still are common. The tools depend on what materials are being used and the level of complexity of the still. Below is an example list of tools that was used for a project in Botswana.[2]

- hacksaw

- measuring tape

- silicone guns

- chisel

- gloves

- level

- fishline (building line)

- wheelbarrow

- shovels

- trowels

- glass cutters

- pliers

- paint brushes

- trimming knives

- flat screwdrivers

- building square

- 2 adjustable spanners

Skills and Knowledge[edit | edit source]

Understanding Solar Stills: Maintenance has a thorough description of maintenance and operational requirements, as well as skills and knowledge needed to build and operate a solar still.

Estimated Costs[edit | edit source]

Understanding Solar Stills: Economics already does a good job of explaining the economics of a solar still and comparing this technology to alternatives. The fact is that solar stills are more expensive than other appropriate water cleaning technologies, but they are reliable, user friendly, and robust.

Case Studies[edit | edit source]

UTC Solar Distiller is a case study of the construction of a solar still in Mexico. The page includes detailed instructions with photos, as well as information about materials and costs.

A citation for a case study from Botswana in micro-fiche format can be found in the references.[2]

References[edit | edit source]

- ↑ McCracken, H., & Gordes, J. (1985). Understanding solar stills. VITA Technical Paper, (37) Retrieved from [1]

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 Yates, R., Woto, T., & Tlhage, J. T. (1990). Solar-powered desalination: A case study from Botswana. Ottawa: International Development Research Centre.

- ↑ 3.0 3.1 3.2 3.3 fckLRAbu-Hijleh, B. A., & Mousa, H. A. (1997). Water film cooling over the glass cover of a solar still including evaporation effects. Energy, 22(1), 43-48.fckLR

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 fckLRDutt, D. K., Kumar, A., Anand, J. D., & Tiwari, G. N. (1993). Improved design of a double effect solar still. Energy Conversion and Management, 34(6), 507-517.fckLR

- ↑ fckLRKalidasa Murugavel, K., Chockalingam, K. K. S. K., & Srithar, K. (2008). Progresses in improving the effectiveness of the single basin passive solar still. Desalination, 220(1-3), 677-686.fckLR

- ↑ Heat transfer. (2010, April 15). In Wikipedia, The Free Encyclopedia. Retrieved 15:56, April 22, 2010, from http://en.wikipedia.org/w/index.php?title=Heat_transfer&oldid=356169993

- ↑ Convection. (2010, April 22). In Wikipedia, The Free Encyclopedia. Retrieved 16:31, April 22, 2010, from http://en.wikipedia.org/w/index.php?title=Convection&oldid=357620678

- ↑ Conduction (heat). (2010, April 21). In Wikipedia, The Free Encyclopedia. Retrieved 16:14, April 22, 2010, from http://en.wikipedia.org/w/index.php?title=Conduction_(heat)&oldid=357403462

- ↑ Thermal radiation. (2010, April 12). In Wikipedia, The Free Encyclopedia. Retrieved 16:18, April 22, 2010, from http://en.wikipedia.org/w/index.php?title=Thermal_radiation&oldid=355601161

- ↑ fckLRSodha, M. S., Kumar, A., Tiwari, G. N., & Pandey, G. C. (1980). Effects of dye on the performance of a solar still. Applied Energy, 7(1-3), 147-162.fckLR

- ↑ fckLRNafey, A. S., Abdelkader, M., Abdelmotalip, A., & Mabrouk, A. A. (2002). Enhancement of solar still productivity using floating perforated black plate. Energy Conversion and Management, 43(7), 937-946.fckLR

- ↑ fckLRArjunan, T. V., Aybar, H. Ş., & Nedunchezhian, N. (2009). An experimental study on solar still with sponge liner. International Journal of Applied Engineering Research, 4(3), 335-361.fckLR

- ↑ 13.0 13.1 fckLRDhiman, N. K., & Tiwari, G. N. (1990). Effect of water flowing over the glass cover of a multi-wick solar still. Energy Conversion and Management, 30(3), 245-250.fckLR

- ↑ 14.0 14.1 fckLRSingh, A. K., & Tiwari, G. N. (1992). Performance study of double effect distillation in a multiwick solar still. Energy Conversion and Management, 33(3), 207-214.fckLR

- ↑ 15.0 15.1 Lawrence, S. A., Gupta, S. P., & Tiwari, G. N. (1990). Effect of heat capacity on the performance of solar still with water flow over the glass cover. Energy Conversion and Management, 30(3), 277-285.