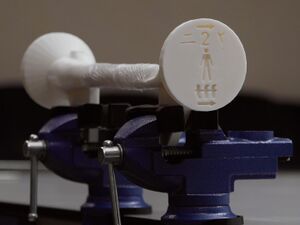

These 3D printed models accurately simulate bone length and diameter, external contour and cross-sectional shape, bicortical anatomy, cortical hardness, cancellous bone porosity, and microstructure, and far cortex thickness for adult males at right humeral shaft fracture pin drilling sites for modular external fixation.[1][2][3][4][5][6][7][8][9][10][11][12][13][14] Each model has a vise attachment to allow the user to secure the model inside a standard vise clamp to maximize safety during simulation training. When a model is placed inside a standard vise clamp, the bone model will be properly positioned to simulate a patient in the supine position. These open-source, locally reproducible, and high fidelity 3D printed bone models teach essential irrigation and debridement, powered and manual drilling, and modular external fixation skills that are transferable to the performance of other limb-saving and life-saving surgeries that require hardware stabilization and fixation.[15]

Find Local 3D Print On Demand Services[edit | edit source]

On-site access to a 3D printer is not required to reproduce these bone models. The open-source 3D files can be downloaded by any 3D printing organization anywhere.

Please click here to find and contact 3D print on demand services in your region.

3D Printing Software, Hardware, and Filament Specifications[edit | edit source]

All 6 requirements below must be met in order to 3D print bone models for orthopedic surgical simulation training.

- Slicing Program: Ultimaker Cura or Cura Lulzbot Edition only

- 3D Printer Type: Fused Filament Fabrication

- Nozzle Size: 0.4 mm

- Minimum Build Volume Z Height: 150 mm

- Print Speed on 3D Printer Control Screen: 100% or less

- Filament: Unexpired White PLA just fresh out of the sealed packaging

Ultimaker Cura, the world’s most popular 3D printing software with millions of users, already has profiles for many commercially available 3D printers, allows you to create a custom profile for other 3D printers, and is open-source and free to download.[16]

We have identified suitable white PLA filament brands for our open-source, high fidelity bone simulators which include but are not limited to:

- Filaments.ca Standard Milk White PLA 1.75 mm or Bone White PLA 1.75 mm Filament (Shore Hardness 84D) which can be shipped to any country;

- Filaments.ca 2.85 mm PLA Filament (requires minimum order of 48 spools) (Shore Hardness 84D) which can be shipped to any country;

- Prusament PLA 1.75 mm Filament (Shore Hardness 81D) which is available in 167 countries and territories;

- Ultimaker PLA 2.85 mm Filament (Shore Hardness 84D) which is available in at least 114 countries and territories through Ultimaker re-sellers (including all 69 countries in the Sub-Saharan, Middle East and North African regions through AIGE Limited); or

- Matterhackers PRO Series PLA 1.75 mm and 2.85 mm Filament (Shore Hardness 80D-88D) which is available in North America.

Any white PLA filament brand with a Technical Datasheet with Shore Hardness D values between 79D-93D is suitable for 3D printing the bone models for orthopedic surgical simulation training.

Download Ready-To-Print GCODE Files[edit | edit source]

If you have a Creality Ender 3 3D printer, please download the ready-to-print g-code files below.

Creality Ender 3 3D Printer[edit | edit source]

| Model # | Print Time | White PLA Filament Weight | Download G-CODE File | Revision Date |

|---|---|---|---|---|

| 1 | 17 hours, 26 minutes | 150 grams | Click here to download g-code or right-click this link and select "Save link as:" File name: Model 1 - Male - Creality Ender 3 - 18-Oct-2022 version and Save as type: .GCODE File | October 18, 2022 |

| 2 | 16 hours, 56 minutes | 144 grams | Click here to download g-code or right-click this link and select "Save link as:" File name: Model 2 - Male - Creality Ender 3 - 18-Oct-2022 version and Save as type: .GCODE File | October 18, 2022 |

You cannot print .GCODE files that are not prepared for your 3D printer.

Download 3D Model STL Files For Slicing[edit | edit source]

Download the two 3D files (.STL) in the table below to input the required print settings to create the print files (.GCODE) for other 3D printers.

| Model # | Download STL File | Revision Date |

|---|---|---|

| 1 | Click on this link and click on "Model_1_-_Male_-18-Oct-2022_version.stl" to download the file. | October 18, 2022 |

| 2 | Click on this link and click on "Model_2_-_Male_-18-Oct-2022_version.STL" to download the file. | October 18, 2022 |

Input Required Print Settings[edit | edit source]

Please pay attention to and input all the required settings below to ensure the bone models are printed properly and display the required visual, tactile, and acoustic fidelity for orthopedic surgical simulation training.

- Slicing Program: only use Ultimaker Cura or Cura Lulzbot Edition

- Filament Material: PLA at all original default settings (click here for image)

- Support: None (click here for image)

- Layer Height: 0.3 mm or less (click here for image)

- Wall Thickness: 5.5 mm (this changes the wall line count)

- Top Layers: 0 (click here for image)

- Bottom Layers: default value (not 0) (click here for image)

- Infill Density: 15% (click here for image)

- Infill Pattern: Tri-Hexagon (click here for image)

- Top/Bottom Speed: 15.0 mm/s (click here for image)

- Build Plate Adhesion Type: No Raft (click here for image)

- Print Speed on 3D Printer Control Screen: 100% or less (click here for image)

If you are not familiar with using Ultimaker Cura or Cura Lulzbot Edition slicing programs, please click here to follow step-by-step instructions to prepare the models for printing.

Inspect Printed Models[edit | edit source]

- Please review the quality assurance checklist below to verify that each model was properly printed.

- If you are a 3D print on demand service provider, please send photos of the base, top, sides and vise attachment of sample printed models to the consignee.

Any model that does not meet the standard for all the quality assurance checklist items must be reprinted in accordance with the instructions outlined below.

| # | Action | Meets Standard | Does Not Meet Standard | Does Not Meet Standard | Check most appropriate response | Check most appropriate response |

|---|---|---|---|---|---|---|

| 1 | Inspect the base. |  |

|

|

Model #1 Meets Standard Model #1 Does Not Meet Standard |

Model #2 Meets Standard Model #2 Does Not Meet Standard |

| 2 | Inspect the top. |  |

|

|

Model #1 Meets Standard Model #1 Does Not Meet Standard |

Model #2 Meets Standard Model #2 Does Not Meet Standard |

| 3 | Inspect both sides. |  |

|

|

Model #1 Meets Standard Model #1 Does Not Meet Standard |

Model #2 Meets Standard Model #2 Does Not Meet Standard |

| 4 | Inspect the vise attachment. |  |

|

|

Model #1 Meets Standard Model #1 Does Not Meet Standard |

Model #2 Meets Standard Model #2 Does Not Meet Standard |

Calculate Pricing[edit | edit source]

Once you have verified the models meet quality assurance standards, please click here to calculate the price of the models and generate an invoice.

All the 3D printed models print support-free and are designed to be made on any single or multi-extruder, fused filament fabrication 3D printer that can use g-code files sliced on Ultimaker Cura or Cura Lulzbot Edition and has a build volume Z height of 150 mm or more.

Inspect Models Before Delivery[edit | edit source]

- Click on this link to print the quality assurance checklist for each shipment of 3D printed models by clicking on the "Download PDF" button in the upper righthand corner of this screen and selecting "Layout: Landscape" option for printing.

- Review the quality assurance checklist to verify that each model was properly printed prior to delivery and click on the checkboxes to check the most appropriate response.

- Write the model production period, total number of Adult Male Humeral Bone Models #1 and #2 accepted, date of inspection, print and sign your name, and fill in the name, address, and phone number of the consignee at the bottom of the checklist.

- Attach the completed and signed checklist to the delivery invoice for the consignee.

- File and save a back-up copy of the completed and signed checklist for your production and inspection and distribution records.

Any model that does not meet the standard for all the quality assurance checklist items must be rejected and will not be delivered to the consignee.

Troubleshooting Guide[edit | edit source]

If you're having problems in properly printing these models, please click on this link and carefully follow the detailed step-by-step instructions.

Cost Savings and Production Efficiency[edit | edit source]

The benefits of 3D printing the Humeral Shaft Transverse Fracture Simulator (3D Printed Adult Humeral Bone Models #1 and #2) locally in Nigeria are that the purchase cost is over 10 times cheaper and the production time is over 163 times faster than purchasing a comparable artificial bone product that is imported from abroad, and the purchase cost is over 3 times cheaper than acquiring a human cadaveric humerus prepared by a local university anatomy lab.[17][18][19]

These data-driven, gender-specific, easy to print, labor-saving, eco-friendly, hygienic, and cruelty-free bone simulation models are not made with natural rubber latex, are designed with safety features to protect users, and can be locally reproduced to offer the highest fidelity, standardized orthopedic surgical simulation training at the lowest cost to medical officers and surgeons who are not orthopedic specialists.

The costs of the 3D Printed Adult Humeral Bone Models will vary depending on the region's 3D printing organizations, and locally available brands of filament. In Nigeria, one 750 gram roll of Ultimaker White PLA filament (Shore Hardness 83D) costs €33 Euros which is equal to about 5¢ USD per gram.[20][21]

In 2022, the 3D Printed Adult Male Humeral Bone Models #1 and #2 produced by a local 3D printing business in Nigeria at 100% scale is $10.25 and $9.90 USD (not including local taxes or shipping costs).[22] The estimated filament weight and printing times for the 3D Printed Adult Male Humeral Bone Models #1 and #2 at 100% scale are 153 grams and 147 grams and 6 hours and 43 minutes, and 6 hours and 32 minutes, respectively.

The Humeral Shaft Transverse Fracture Simulator is easy and quick to assemble and does not require any tools, specialized equipment, technical expertise, or time-consuming preparation to build, install, operate and maintain this simulator within the intended place of use. By purchasing locally made 3D printed bone models for modular external fixation skills training, the learner also supports the local economy while saving on customs dues, processing fees, and international shipping costs that would be incurred when using artificial bone products that are not made locally.

2022 Comparison of Humeral Shaft Transverse Fracture Simulator Locally Made in Nigeria to Human Cadaveric Bone and a Commercially Available Artificial Bone Product| Humeral Shaft Transverse Fracture Simulator

(3D Printed Adult Humeral Bone Models #1 and #2) |

Human Cadaveric Humerus

(Prepared by an University Anatomy Lab in Nigeria)[19] |

Sawbones Humerus, 4th Gen., Composite, 10 PCF Solid Foam Core, Large, Left

(SKU:3404-4)[23] | |

|---|---|---|---|

| Bone Simulator Dimensions | Humerus with an overall length of 33 cm. | Varies.[1][2] | Humerus with an overall length of 36.5 cm.[23] |

| Bone Simulator Features | 3D printed anatomic bone models reproduce bicortical anatomy, cortical thickness, and cancellous bone to provide acoustic fidelity when drilling through the bone simulator. |

|

Humerus contains "short fiber filled epoxy as the simulated cortical bone material," "a 10 PCF density cancellous foam core, and a 9 mm diameter canal."[23] |

| Tactile Fidelity | Made of biorenewable plastic with a hardness level that is very similar to human cortical bone to allow learners to develop the skills to prevent plunging through the far cortex. | Human cadaveric humeral bone | Sawbones Composite Bones are the only Sawbones products that "mimic the [biomechanical] properties of human bones," and "are used as alternative testing media to human cadaver bone."[23][24] |

| Visual Fidelity | Yes. White colour | Yes. White colour | No. Gray/green colour[23] |

| Fracture Simulation | Simulates a transverse mid-shaft fracture of the humerus for modular external fixation training. | Requires additional preparation to simulate a fracture. | Requires additional preparation by user to simulate a fracture. |

| Fracture Encapsulation | Encapsulates transverse fracture with cellophane. | No. This would incur additional preparation and storage fees. | Does not encapsulate or re-attach fracture. |

| Vise Attachment | Contains a vise attachment to safely secure the model inside a standard vise clamp. | Does not contain a vise attachment. | Does not contain a vise attachment which mandates the use of specialized vise clamps that cost up to $214 USD to properly secure the model to a table for safe simulation training for learners. |

| Production Time | 13 hours 15 minutes (when Adult Male Humeral Bone Models #1 and #2 are printed consecutively). | Depends on local availability of cadaver specimens which is difficult to predict. | Ready to ship in 84 days or more.[23] |

| Unit Cost | $20.15 USD[22] | $75.00 USD[19] | $229.75[23] |

Noteː A product comparison was not made with the:

- Sawbones Humerus, Solid Foam, Right, ($15.00 USD) because this model simulates a 9.5 mm diameter intramedullary canal and does not simulate cancellous bone or an accurate cortical thickness for the target patient population, and the foam material does not simulate the hardness of cortical bone, and thus, could foster anti-skills because this model does not provide the tactile fidelity necessary to develop the skills to prevent plunging through the far cortex;

- Sawbones Humerus with Oblique Fracture, Foam Cortical ($41.50 USD) because this model's rigid foam shell cuts and drills easier than the plastic cortical shell models and thus, could foster anti-skills because this model does not provide the tactile fidelity necessary to develop the skills to prevent plunging through the far cortex, and this model contains natural rubber latex which can trigger latex sensitivities and potentially life-threatening allergic reactions in healthcare workers; and

- Sawbones Humerus, Plastic Cortical Shell, Left ($42.00 USD) because these models do not provide the tactile fidelity necessary to develop the skills to prevent plunging through the far cortex.[18][25][26][27]

Acknowledgements[edit | edit source]

This work is funded by a grant from the Intuitive Foundation. Any research, findings, conclusions, or recommendations expressed in this work are those of the author(s), and not of the Intuitive Foundation.

References[edit | edit source]

- ↑ 1.0 1.1 Singh, Anudeep & Kumar, Anil. (2014). An Anthropometric Study of the Humerus in Adults. RESEARCH AND REVIEWS: JOURNAL OF MEDICAL AND HEALTH SCIENCES. 3. 76-81.

- ↑ 2.0 2.1 Mall G, Hubig M, Büttner A, Kuznik J, Penning R, Graw M. Sex determination and estimation of stature from the long bones of the arm. Forensic Sci Int. 2001 Mar 1;117(1-2):23-30. doi: 10.1016/s0379-0738(00)00445-x. PMID: 11230943.

- ↑ https://3dprint.nih.gov/discover/3dpx-016808

- ↑ Society For Biomaterials 30th Annual Meeting Transactions, page 332. Femoral Cortical Wall Thickness And Hardness Evaluation. K. Calvert, L.A. Kirkpatrick, D.M. Blakemore, T.S. Johnson. Zimmer, Inc., Warsaw, IN.

- ↑ Ultimaker. Ultimaker PLA Technical Data Sheet [Internet]. Ultimaker Support. [cited 2021 July 29]. Available from: https://support.ultimaker.com/hc/en-us/articles/360011962720-UltimakerPLA-TDS.

- ↑ https://support.ultimaker.com/hc/en-us/articles/360011962720-Ultimaker-PLA-TDS

- ↑ Vian, Wei Dai and Denton, Nancy L., "Hardness Comparison of Polymer Specimens Produced with Different Processes" (2018). ASEE IL-IN Section Conference. 3. https://docs.lib.purdue.edu/aseeil-insectionconference/2018/tech/3.

- ↑ Forrest AM, Johnson AE, inventors; Pacific Research Laboratories, Inc., assignee. Artificial bones and methods of making same. United States patent 8,210,852 B2. Date issued 2012 Jul 3.

- ↑ National Institutes of Health Osteoporosis and Related Bone Diseases National Resource Center. What is Bone? [Internet]. Bethesda (MD): The National Institutes of Health (NIH); 2018. [Cited 2021 Aug 17]. Available from: https://www.bones.nih.gov/health-info/bone/bone-health/what-is-bone.

- ↑ Meyers, M. A.; Chen, P.-Y. (2014). Biological Materials Science. Cambridge: Cambridge University Press. ISBN 978-1-107-01045-1.

- ↑ Meema HE, Meema S. Measurable roentgenologic changes in some peripheral bones in senile osteoporosis.J Am Geriat Soc 1963;11:1170-82.

- ↑ Bloom RA. A comparative estimation of the combined cortical thickness of various bone sites. Skeletal Radiol. 1980;5(3):167-70. doi: 10.1007/BF00347258. PMID: 7209568.

- ↑ Bloom RA, Laws JW. Humeral cortical thickness as an index of osteoporosis in women. Br J Radiol 1970; 43:522-7.

- ↑ Tingart MJ, Apreleva M, von Stechow D, Zurakowski D, Warner JJ. The cortical thickness of the proximal humeral diaphysis predicts bone mineral density of the proximal humerus. J Bone Joint Surg Br. 2003 May;85(4):611-7. doi: 10.1302/0301-620x.85b4.12843. PMID: 12793573.

- ↑ Debas, H. T., P. Donkor, A. Gawande, D. T. Jamison, M. E. Kruk, and C. N. Mock, editors. 2015. Essential Surgery. Disease Control Priorities, third edition, volume 1. Washington, DC: World Bank. doi:10.1596/978-1-4648 -0346-8. License: Creative Commons Attribution CC BY 3.0 IGO.

- ↑ https://ultimaker.com/software/ultimaker-cura

- ↑ AIGE Limited. 3D printers. [Internet]. 3D Printers|AIGE Limited. [cited 2021 July 29]. Available from: https://www.aige.info/3d-printers.

- ↑ 18.0 18.1 https://www.sawbones.com/humerus-large-right-solid-foam-length-36cm-canal-diameter-9-5mm-1019-20.html

- ↑ 19.0 19.1 19.2 Dr. Habila Umaru. Personal communication. July 20, 2022.

- ↑ Ultimaker. Ultimaker PLA Technical Data Sheet [Internet]. Ultimaker Support. [cited 2021 July 29]. Available from: https://support.ultimaker.com/hc/en-us/articles/360011962720-UltimakerPLA-TDS.

- ↑ Kuunda 3D Ltd. Personal communication. July 14, 2021.

- ↑ 22.0 22.1 AIGE Ltd. Personal communication. July 29, 2022.

- ↑ 23.0 23.1 23.2 23.3 23.4 23.5 23.6 https://www.sawbones.com/humerus-large-left-4th-generation-composite-w-10-solid-foam-cancellous-core3404-4.html

- ↑ Elfar J, Menorca RM, Reed JD, Stanbury S. Composite bone models in orthopaedic surgery research and education. J Am Acad Orthop Surg. 2014 Feb;22(2):111-20. doi: 10.5435/JAAOS-22-02-111. PMID: 24486757; PMCID: PMC4251767.

- ↑ https://www.sawbones.com/humerus-large-foam-cortical-shell-w-cancellous-w-oblique-mid-diaphyseal-fx-1028-22.html

- ↑ Recommendations For Labeling Medical Products To Inform Users That The Product Or Product Container Is Not Made with Natural Rubber Latex Guidance For Industry And Food and Drug Administration Staff [Internet]. United States Food and Drug Administration; 2014 [cited 2021 Nov 28]. Available from: https://www.fda.gov/media/85473/download.

- ↑ https://www.sawbones.com/humerus-large-left-white-plastic-cortical-shell-w-cancellous-length-36cm-9-5mm-canal1006.html