Technical Guide for Tilapia Farming (CDI, 1998, 51 p.)

PART THREE: FISH FARMING EQUIPMENT AND RECOMMENDED EUROPEAN SUPPLIERS

Fish farming equipment[edit | edit source]

The equipment requirements of a project depend largely on the type of rearing to be done and the level of production envisaged. The degree of the use of automation needs to fit within the global context of the project.

Pumping[edit | edit source]

When it is not possible to have a water supply by gravity, pumping needs to be studied. It is not advised, at this time, to implement an intensive fish farm in tropical countries on a site where pumping is required; for an intensive commercial production (300/400 tonne per year), a flow exceeding 1,000 m3/h will be necessary. When pumping is necessary, it is more appropriate to consider extensive or semi-intensive farming under tropical conditions

Water needs for extensive systems are not so high as for the other alternatives described. In these conditions, the water supply should compensate the water lost through evaporation and infiltration into the soil. In a semi-intensive system, a water exchange of 15 to 25% per day has to be accounted for.

In order to evaluate exact pumping needs, the calculation will be based on the water requirements of the rearing system, the size of the ponds, on the soil nature (losses through infiltration) and also the climate (rainfall and evaporative loss). Each case demands a specific study that will determine the type of pumps to be used and their capacity.

Harvest[edit | edit source]

The equipment for this is the basic (and most used) equipment in fish farming. Nets for harvest must be adapted to the facilities (i.e. the size and depth of ponds). Large mesh nets must be used for harvesting bigger fish while small mesh nets must be foreseen for fry. Nets must be well maintained and be checked after each use, in order to maintain an efficient standard of operation. Not only the condition of the mesh but also floats and ballast must be subject to constant checks.

Aeration[edit | edit source]

There are two main types of aeration systems used in commercial aquaculture.

Aeration by pulsed air: A blower generates air at relatively low pressure through pipes to air stones or other diffusers. This system is particularly well adapted to small-scale facilities and for fry and small fish since it does not cause damage due to water turbulence.

Aeration by mechanical agitation: There are many different types of aerators (fountain aerator, paddlewheel, and Venturi system) and each has strong and weak points.

- Fountain aerators suck the water from the bottom of the pond and throw it into the air as a fountain. This is done very simply by the use of a motor-driven propeller. It is a very efficient aeration system because it takes the water from the bottom that is poor in O2 and creates an important water movement within the pond. The main disadvantage is that it creates waves that can damage the dams of the ponds by erosion and a build-up of heavy silt underneath the aerator, imposing maintenance of the pond structure at regular intervals.

- Paddle wheel aerators use motor-driven paddles on floats to throw the water into the air for aeration and create a movement on the surface of the pond. While these might be not seen to be so efficient as the fountain aerator, on the other hand, they offer the advantage of creating less erosion and of not creating turbidity.

- The aerators equipped with a Venturi system are also very efficient because the system creates an important aeration effect and induces a good gaseous exchange. They can sometimes cause turbidity and create a hole on the bottom of the pond if the flow is badly oriented or if the ponds are not deep enough.

The selection of the aeration system needs to be done following the type of facilities being used (earth ponds, concrete pond, size of the facilities etc.) and the rearing conditions applied (density, fish size, etc.)

Notes:

These different types of aerator are available in different motor powers, for scaling to the size of ponds and/or stocking densities to be used.

In a hyper-intensive system, the relationship between the kilowatts consumed and the feed distributed has been followed: this corresponds to approximately 1 kW consumed per Kg of food distributed.

Another oxygenation system is the "super-saturation oxygen" system, which is mainly used in [[Trout] farming. This system super-saturates the water in oxygen and therefore allows even higher rearing densities while easing the digestion for the fish. In tropical aquaculture, it is premature to envisage this type of installation due to expense.

Fish graders[edit | edit source]

Fish graders are used to grade and separate fish according to their individual size. This operation is very important because it allows a dramatic improvement in growth performance and improves the overall management of the use of the farm's facilities. If the fish are not graded properly, the smallest ones have difficulty in gaining access to the food (due to physical competition with larger fish) and are stressed, resulting in poor growth performance. Since the size of fish pellets is uniform, the fish size must also be uniform. There are two main types of fish grading equipment:

- Manual fish graders: They are made of boxes that are fitted with differently sized screens, each relating to a range of physical fish size. It is a very simple system that allows small fish to go through the screen while retaining the larger ones in the box. An advantage of the system is that it does not require any electric energy. However, it generates more stress than an automatic grader that is due to heavier handling of the fish.

- Mechanical graders are more sophisticated. Without going into details, it is a machine that is able to grade fish into 3, 4 or 5 different size batches. The system is made of 2 mobile bands or rollers, fixed opposite each other with, a gap between that becomes progressively wider. Fish are conveyed between the bands, being constantly sprayed with water, and they then fall through the gap when the width (corresponding to their size) allows it, smaller fish falling through first. Fish are then transferred to the different tanks through plastic pipes by gravity. The main advantage of this system is that the job is done quickly and without excessive damage to the fish. In intensive fish farming, this type of equipment is very interesting to use, especially when temperatures are high and the fish must be handled with care.

As complementary equipment to the fish grader, fish counters can also be used, often called "bioscanners"; it consists of an electronic register/counter that is placed at the end of an outlet of the fish grader. Using this equipment, the exact number of fish is known after the grading.

Fish pumps & fish elevators[edit | edit source]

This equipment is used to move fish out of the growing units for grading, for loading on a truck or simply for harvest.

Fish pumps function on the same principles as water pumps; they suck fish and water together and pump them out afterwards. All of the movement is done through (flexible) pipe-work. This system is particularly well adapted to floating cage culture.

Fish elevators are based on the concept of the Archimedes screw. This system lifts the water and the fish together.

These two systems are adaptable to a large variety offish sizes (from few grams to more than 5 kg) and species. When high production levels are envisaged, this equipment is very useful indeed almost essential. The ratings for this type of machinery can reach 10 tonnes of fish per hour for the biggest ones.

Feeding[edit | edit source]

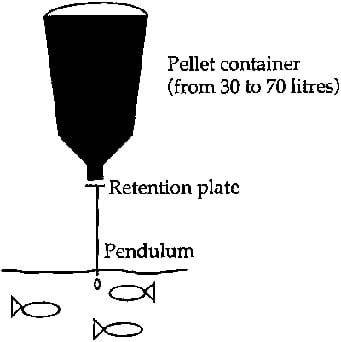

There are numerous feeding systems. As discussed in the chapter on nutrition, tilapia is a fish that must be fed often with small quantities. Demand feeders are then particularly well adapted to this fish.