This method provides instructions on the use of the MOST Recyclebot V 6.1.

Introduction[edit | edit source]

Coming soon...

Safety[edit | edit source]

- Plastic will be hot and may pop during set-up. Safety glasses should be worn at this time.

- Fan blades are sharp. Use cation.

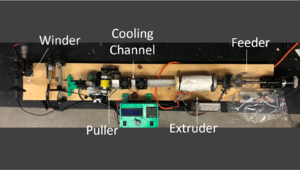

Sections[edit | edit source]

- Feeder

- Extruder

- Cooling Channel

- Puller

- Winder

Operation & Procedure[edit | edit source]

- Plug in Recyclebot using orange cord.

- Turn Recyclebot on using switch on lower right side of heater.

- Using set controls on the controls box, set the desired temperature. Hit the up arrow, move the decimal to desired place using left arrow, and hit up/down arrow until desired set temperature is reached.

- Screw empty filament spool onto winder.

- Wait until desired temperature is reached.

- Turn motor on using the small black switch located on the center of the breadboard.

- Fill feeder with pellets.

- Remove metal channel. Allow old plastic to run through the extruder, collect on paper.

- When new plastic is visible, replace metal channel, and turn on yellow motor to a slow speed.

- Pull filament in order to get a small diameter, and guide filament through yellow motor and diameter measuring chamber.

- Connect filament to the spool. Turn on winder motor.

- Turn fans on and adjust to desired speed. Place on top metal tray.

- Allow filament to be wound around the spool. Add filament to chamber, adjust motor speed, fan speed and temperature as needed.

Shutdown[edit | edit source]

- When no more pellets can be seen in the feeder, turn the black switch off.

- Cut the filament near the head of the extruder, and allow last of filament to be wound around the spool.

- Turn off all motors.

- Reduce target temperature of the Recyclebot, allow to cool, shut off and unplug.

References[edit | edit source]