Safety Training Requirements[edit | edit source]

- Dr. Pearce Safety Lab Tour

- Worker Health & Safety Awareness

- WHMIS 2015 - Workplace Hazardous Materials Information System

- Laboratory Safety & Hazardous Waste Management

Safety Instructions[edit | edit source]

1. Always protect your eyes and skin

In this setup, 1M KOH solution serves as the electrolyte. KOH is alkaline and, while not considered dangerous, it can irritate the skin and eyes. Avoid prolonged contact with the skin and keep the electrolyte away from your eyes. If the electrolyte comes into contact with your eyes or skin, promptly rinse it off with plenty of cold water. If any discomfort persists, seek medical attention to prevent any potential issues. To avoid problems,

- Wear protective gloves

- Safety glasses all the time during electrolysis.

- Also wear cloths that fully cover your body

2. Always apply accurate voltage to the electrolyzer

This electrolyzer membrane is highly sensitive to voltage. The recommended voltage is 2V per cell and 6V for this setup. Under no circumstances should this voltage level be exceeded, as it may result in membrane damage.

3. Avoid being electrocuted

- Remember to wear protective rubber gloves when handling electrical components.

- Always power off the equipment before making any adjustments to the setup. Avoid touching the electrolyte, electrodes, and iron objects with bare hands when the power is applied.

4. Always keep the membrane hydrated

- Ensure that the electrolyzer's membrane remains hydrated at all times, even when it is not in operation. Turn on the electrolyte circulation pump once a day and keep it running for an hour. If the membrane dries out, it may crack and lead to an unwanted short circuit.

- Verify that the setup is adequately protected against short-circuits, as accidental short-circuits can result in irreversible damage to the power supply and pose a hazard to human safety.

5. Prevent accumulation of explosive hydrogen and oxygen gases

When there is inadequate ventilation and high concentrations of hydrogen and oxygen gases are mixed, a highly flammable and explosive mixture can form. A single spark between a power clamp and an electrode can result in a violent explosion, with the fire burning at approximately 4280 °F (2360 °C), potentially causing serious injuries.

To prevent the accumulation of explosive hydrogen and oxygen gases, please follow these precautions:

- Ensure that electrolysis is conducted in a well-ventilated area, or preferably, outdoors, to allow the gases to dissipate safely.

- Never seal the electrolytic bath with a tight lid, as this can lead to an increase in gas pressure and higher gas concentration levels.

- Always turn off the power before making adjustments to the setup.

- Keep all potential sources of ignition (e.g., flames, torches, etc.) away.

- Avoid placing the power supply too close to the electrolytic setup to minimize the risk of unwanted sparking.

6. Keep the electrolysis setup undisturbed

Electrolysis process should be carried out in the mentioned designated location. For relocation,

- It must be situated away from human traffic to prevent accidental contact.

- For outdoor setups, it should be protected from stray and wild animals, falling branches and leaves, and strong winds

Working Environment[edit | edit source]

Temperature

- Operating: 20℃ to 70℃

Ventilation

- Please ensure that the air intake and exhaust areas are unobstructed and have a free flow of air. When operating the electrolyzer in a fume hood, provide ample clearance above and at least 15 cm behind the instrument to ensure proper ventilation.

Hazardous material and electrical equipment

- Keep all potential sources of ignition (such as flames, torches, etc.) away as well as electrical equipment (DC power supply and computers) outside the fume hood area.

Care

- Do not leave the electrolyzer unattended while it is operating.

Cleaning

Please follow these steps to regularly change the electrolyte and clean the setup (after 16 hours of electrolyzer operation):

- Begin by disconnecting the pump and the electrolyzer stack from all power sources, and then clean the surfaces using a soft, damp cloth.

- Dispose of all the electrolytes in the sink after adding a small amount of cold water to dilute them.

- While cleaning, do not disconnect any existing plumbing or electrical connections.

- After cleaning, ensure that there are no leaks in the pipes or loose electrical connections.

AEM Electrolyzer[edit | edit source]

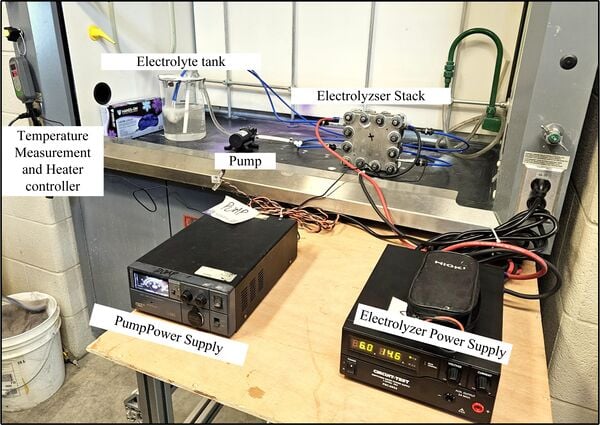

- Location: FAST laboratory, Room TEB 06, Thomson Engineering Building, Western University, London, Ontario, Canada

- Vendor: Cipher Neutron [1]

- Name: Cipher Neutron

- Address: 501 Alliance Ave, Toronto, ON M6N 2J1

- Phone: +1 647 803 0002

- Email: info

cipherneutron

cipherneutron com

com - Site: cipherneutron.com/

3. AEM Electrolyzer specifications:

- AEM Electrolyzer

- Number of Cell: 3

- Active area: 50cm2

- Electrolyte: 1M KOH

- Power source: DC Power (6V, 10A-100A)

- Maximum temperature: 700 C

Installation & Maintenance[edit | edit source]

Installation process:

- The AEM electrolyzer consists of three cells, each requiring a 2V DC voltage to operate (total 6V), with a maximum current capacity of 100A depending on the electrolyzer's temperature. However, given the available power supply unit, there is no heater connected to the system. The system's operating temperature is approximately 26 degrees Celsius, allowing for a maximum current of around 16A.

- Continuous operation will lead to an increase in temperature, subsequently raising the current output. The system is equipped with a temperature measurement unit, with a maximum set-point of 70 degrees Celsius, which can control a heater if one is installed.

- A pump, designed for a larger electrolyzer model, is also connected and operates on 12V DC to circulate the electrolyte. To ensure the appropriate water flow, the applied voltage to the pump is controlled at 10V.

- A 3-liter tank is used to store 2L electrolyte, which needs to be changed every 16 hours of operation. Currently, the tank holds an electrolyte containing both hydrogen and oxygen, although no hydrogen collection is taking place at this time. Finally, the electrolyzer is connected to a 30V, 30A power supply, which must be operated carefully to maintain a voltage of approximately 6V across the cells.

Electrolyte changing requirement:

- The AEM electrolyzer requires 1M KOH electrolyte, and it needs to be changed every 16 hours of operation. After 16 hours of use, the color of the electrolyte will change due to the presence of metals and chemical reactions.

Operation & Procedure[edit | edit source]

Follow these steps for operating and shutting down the system safely:

- Activate the ventilation system: Before starting the system, ensure that the ventilation system is functioning properly, and check for any accumulated hydrogen inside the fume hood.

- Power up the pump supply and inspect the water flow: Start by turning on the pump and examine the water flow through the electrolyzer. The voltage supply knob should already be set at 10V, which is suitable for this system. If the water flow appears to be low, gradually increase the voltage if necessary.

- Check for any leaks: Verify that there are no leaks in the electrolyzer's pipes. Proceed to the next stage only after confirming everything is leak-free.

- Activate the stack power supply: Turn on the power supply and slowly increase the supply voltage and current. Initially, set the voltage to 6V and adjust the current to its maximum, allowing for a current of 14-15A, depending on the temperature. Use a multi-meter to measure the voltage across the stack. Although the DC voltage supply is fixed at 6V, there will be some voltage drop in the wires. Adjust the voltage to ensure that the voltage across the stack remains at 6V. At this stage, hydrogen should be produced in the system, so always ensure that there isn't an excessive accumulation of hydrogen inside the fume hood.

- Monitor temperature: While the system is in operation, continuously monitor the temperature and ensure that the temperature remains well below 70 degrees at all times.

- Shutdown procedure: When shutting down the system, first slowly reduce the power supply to the stack to zero. Then, check the system's temperature. Do not turn off the pump until the system's temperature has decreased to room temperature. Allow the pump to continue running, and as soon as the temperature has reduced, turn off the pump and unplug all power supplies from the wall outlets

References[edit | edit source]