In many countries, disposing of PET bottles has caused a major problem. Recycling these bottles proves a difficult challenge. This Bottle Stripper turns PET bottles into long strips that can be used to weave baskets, use as fishing line, use as a type of rope, or possibly even as 3D printer filament. This design spools the strips automatically as it operates.

-

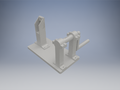

Completed Assembly

-

Printed Assembly

-

Bottle Stripper

-

Mounting Base

-

Razor Clamp

-

Spool Clamp

-

Spool Handle Part 1

-

Spool Handle Part 2

-

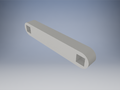

Spool Rod

-

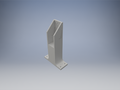

Spool Stand

Bill of Materials[edit | edit source]

- 1 - File:BottleStripper v2.stl

- 1 - File:Mounting Base v2.stl

- 1 - File:Razor Clamp v2.stl

- 2 - File:Spool Clamp v2.stl

- 1 - File:Spool Handle 1 v2.stl

- 1 - File:Spool Handle 2 v2.stl

- 1 - File:Spool Rod v2.stl

- 2 - File:Spool Stand v2.stl

- 6 - M3X10mm Bolts

- 8 - M3X16mm Bolts

- 14 - M3 Nuts

- 10-20 - M3 Washers

- Many - Standard Utility Blades

Tools needed[edit | edit source]

- Athena Delta RepRap or equivalent 3D printer

- PLA or ABS plastic filament

- .STL Slicer program (Cura/Slic3r/etc.)

- Appropriate driver for chosen bolts

Skills and knowledge needed[edit | edit source]

- Proficient knowledge in 3D printer operation

- Basic mechanical assembly skills

Technical Specifications and Assembly Instructions[edit | edit source]

- Download files listed above

- Print specified number of parts

- Clean parts as needed with a razor blade

- Assemble parts as shown in the Completed Assembly photo above.

- Use 10mm bolts to clamp razor blade and spool rod

- Use 16mm bolts to secure parts to base (add washers as needed if bolts stick too far past bottom of the base)

Common Problems and Solutions[edit | edit source]

- Cutting slots may need trimming before use

- Bottles tend to begin to cut into plastic stripper over time. May need to replace with metal substitute.

Cost savings[edit | edit source]

- ~252grams plastic filament - ~$7.32USD @ $29USD/kg

- $1.89 in hardware from McMaster.com

- 50 pack of utility blades $9.58 on Amazon

- Total cost ~$18.79

- No commercial equivalent can be found (other self made solutions, but no detailed drawings found)

- Savings is in time from self-spooling action

Additional Files[edit | edit source]

Below is are the.SCAD files used to create this device.

- File:Completed Assembly v2.scad

- File:BottleStripper v2.scad

- File:Mounting Base v2.scad

- File:Razor Clamp v2.scad

- File:Spool Clamp v2.scad

- File:Spool Handle 1 v2.scad

- File:Spool Handle 2 v2.scad

- File:Spool Rod v2.scad

- File:Spool Stand v2.scad

References[edit | edit source]

- Utility Knife Blade Inventor model. Converted into.STL for use in OpenSCAD: https://grabcad.com/library/standard-utility-knife-blade

- http://www.utsumi.com.br/pet/English/filetador/index.html

- http://web.archive.org/web/20160222000558/http://www.livedebris.org:80/Photos/Art%20photos/Tutorials/bottle%20cutter%20tutorial.pdf

- https://www.appropedia.org/PET_Bottle_Shredder