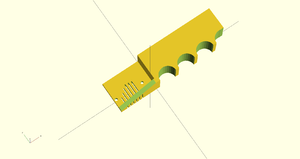

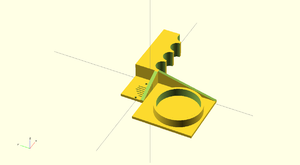

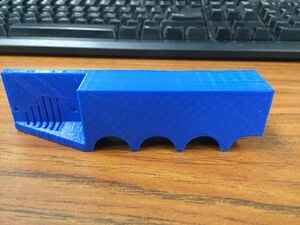

Included below is three different designs for PET bottle shredders currently designed for 20oz soda bottles but easily expandable for use with 2 liter soda bottles. The first design is a simple hand held shredder which is the simplest design and uses the least plastic. This makes this design ideal for areas which have access to a 3D printer but which filament might not be as readily available. The second design adds a bottle holder to the simple hand held shredder. This holder was added to possibly aid in efficiency. The third design is a hand cranked design which also uses a bottle holder and spools the cut filament. These shredders allow the use of the cut PET to be used in things like crafts and possibly for printing purposes.

Bill of Materials[edit | edit source]

- 3-D printer

- OpenScad

- PLA filiment

- Single sided razor blade

- 2 M3x6mm screws

- 2 M3 nuts

Files:

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- OpenScad or other Cad software http://www.openscad.org/

Skills and knowledge needed[edit | edit source]

- Basic knowledge of your 3-D printer and software used to make the model.

- Proficiency with a slicer program and some basic hand tool knowledge.

Technical specifications and assembly instructions[edit | edit source]

- Download the files listed above

- Prepare your printer and load the.stl file and slice into a.gcode file

- Print cutter and clean any flash on the cutter slots

- Attach razor blade via the 2 M3 screw slots

Print time: 2 hours for simple cutter at 20% infill

Assembly time: amount of time it takes to attach razor blade, approximately 2 minutes

Common problems and solutions[edit | edit source]

The cutter slots may not print fully open and will need to be trimmed with a razor blade. Cutter slots may not also print with even opening spacing.

Cost savings[edit | edit source]

Hand cutter:

- 29.58 grams of filament and approximately 120 minutes

- $0.52 per cutter assuming filament costs of $20/Kg + whatever you value the time to set the print up at

Commercial equivalent:

- No such thing exists