For further details and information, please click on the link corresponding to the related published paperː

1. Introduction[edit | edit source]

Considering the growing trend of energy consumption due to the world's population growth and negative environmental consequences of fossil fuel consumption, industrial and agricultural sectors are getting forced to reduce their greenhouse gas (GHG) emissions while enhancing the efficiency of their sites. In this regard, in addition to technological advancements taking place in manufacturing and process engineering areas, recovery of waste heat from energy conversion processes is a promising strategy to reach the above-mentioned goal (Jouhara et al., 2018)[1]. To put the importance of this strategy into a more vivid picture, the conclusion of numerous studies indicates that about 20-50% of industrial energy inputs are lost as waste heat (Johnson et al., 2008)[2].

The feasibility of Waste Heat Recovery (WHR) and its application depend on several factors, the most important of which include (Johnson et al., 2008):[2]

- Heat loss quantity

- The quality/ temperature of waste heat

- The chemical and physical composition

- Minimum allowable temperature

- Operating limitations, availability, etc.

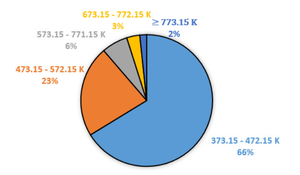

The major sources of waste heat include any type of heat loss (radiation, conduction, and convection) from products, equipment, and processes (Thekdi & Nimbalkar, 2015)[3]. The amount of waste heat is the first parameter confining the applications of WHR from space heating to power generation. Moreover, the waste heat is also classified based on its quality into high temperature (≥400 °C), medium temperature (100-400 °C), and low temperature (≤100 °C) ranges (Brückner et al., 2015)[4]. In addition, especially in waste heat recovery of combustion gases, the minimum allowable temperature is crucial for engineers and heat exchanger designers to consider the condensation temperature of water vapor in flue gas mixture, so prevent the heat exchangers from corrosion and failure caused by corrosive substances (CO2, NOx, and SOx) of the moisture on the surfaces. These parameters not only indicate the WHR effectiveness, but also determine the heat transfer rate, heat exchanger's surface area, and suitable materials to be used.

The chemical composition and phase of streams with waste thermal energy are one of the most effective parameters in design, material selection, and costs of heat exchangers construction and maintenance in the WHR process.

The application for which the waste heat recovery is considered and a suitable heat exchanger is designed has different characteristics limiting the feasibility of WHR strategy. The accessibility of waste heat sources, the transportability of waste heat streams, the scale of application, operating schedules (availability time of waste heat sources), the requirement for additional equipment like energy storage systems and extra piping systems, and finally, affordability and economically feasibility of waste heat recovery are significant factors must be considered by engineers.

1.1. Waste heat recovery applications[edit | edit source]

Waste heat recovery is generally applicable for preheating and recuperative processes (e.g., combustion air preheating, boiler feed water preheating, batch preheating in glass furnaces, and domestic hot water preheating), mechanical and/or electrical power generation (e.g., power generation from waste heat of a gas turbine cycle via steam Rankine cycle), being involved in chemical processes (e.g., pretreatment of wastewater for biogas production) and space heating and cooling (e.g., using the heat pump for heating/cooling applications) (Johnson et al., 2008).[2]

1.2. Low-temperature waste heat recovery challenges[edit | edit source]

It is expressed by Haddad et al. (Haddad et al., 2014)[5] that there are plentiful opportunities to recover low-temperature waste heat as most industrial, agricultural, and domestic waste heat is available in this range. Nevertheless, there are also more challenges facing engineers in low-temperature WHR than in medium or high-temperature ones:

First and foremost, since basically the rate of all types of heat transfer (conduction, convection, and radiation) is directly interconnected to the temperature difference between two substances or two locations, it will be required to build large heat exchangers with large heat transfer surface areas to recover the low-temperature waste heat.

Although it is not required to supply expensive materials like what is needed in high-temperature applications, low-temperature streams make the components of gas mixtures to be condensed, thereby causing corrosion in pipes and heat exchangers (Jouhara et al., 2018).[1]

Last but not least, low-temperature waste heat can be merely used in limited applications such as domestic water and space heating/cooling, which makes it challenging for engineers to find a suitable technology and provide proper instrumentation for the application, temperature enhancement, and transferring of low-temperature waste heat.

1.3. Agricultural and livestock applications of waste heat recovery[edit | edit source]

In contrast to urban and industrial utilization of waste heat, most agricultural operations require low-temperature thermal energy (Yarosh et al., 1972)[6]. As a result, agricultural and livestock fields that are located close to industrial centers or have access to renewable energy sources (solar, geothermal, wind, biomass, etc.) can be potentially considered as the waste heat users. The combination of various industrial/agricultural centers with the aim of waste heat recovery is called the industrial symbiosis. Agricultural and livestock complexes can also provide all or part of their own energy demands by utilizing the waste heat of any component inside of the plants (e.g., agricultural machinery, stationary engines, conventional heaters, warm ventilation air, etc.).

Despite the benefits of waste heat recovery in agricultural and livestock plants, some obstacles hinder energy provision for these plants. The question of how much waste heat from industries in the vicinity is available, especially for the large-scale greenhouses, poultry, etc. is one of the most challenging concerns for designers. Furthermore, in some cases, engineers have to assess the practical aspects (feasibility, accessibility, economic benefit) of the exploitation of available low-temperature waste heat sources. In further steps, scientists should compose an optimization problem and/or a control platform for the provided WHR system (Yarosh et al., 1972).[6]

Heat Recovery from Poultry Processing Scald Water (Shupe & Whitehead, 1979)[7][edit | edit source]

Shupe, W. L., & Whitehead, W. K. (1979). "Heat recovery from poultry processing scald water". Journal of Agricultural Engineering Research, 24(3), 325–330. https://doi.org/https://doi.org/10.1016/0021-8634(79)90074-X

The waste heat of a scald tank outlet water in a poultry processing plant was transferred to the cold replacement water by W. L. Shupe and W. K. Whitehead. They could transfer 102 kW of thermal energy to cold inlet water in winter (about 32%) and 54.6 kW in summer.

Extraction of Energy from an Aerobic Farm Waste Lagoon (Hughes, 1984)[8][edit | edit source]

Hughes, D. F. (1984). "Extraction of energy from an aerobic farm waste lagoon". Journal of Agricultural Engineering Research, 29(2), 133–139. https://doi.org/https://doi.org/10.1016/0021-8634(84)90067-2

D. F. Hughes assessed the practical energy and economic aspects of heat recovery from an aerobic farm waste lagoon employing a water-source heat pump. The temperature of the lagoon (as the heat source) was constant at 35 °C in summer and winter, and the hot water temperature at the outlet of the heat pump was 55 °C. The whole process was studied for one year.

- The heat pump could provide 21.6 kW of thermal demands for the pig farm.

- The operation of this heat recovery system required a minimum of farm labor and resources.

- Considering the maintenance costs and the increment of fuel cost, the payback period of 3-4 years has been deducted for this system.

Field study on effects of a heat exchanger on broiler performance, energy use, and calculated carbon dioxide emission at commercial broiler farms, and the experiences of farmers using a heat exchanger (Bokkers et al., 2010)[9][edit | edit source]

Bokkers, E. A. M., van Zanten, H. H. E., & van den Brand, H. (2010). "Field study on effects of a heat exchanger on broiler performance, energy use, and calculated carbon dioxide emission at commercial broiler farms, and the experiences of farmers using a heat exchanger". Poultry Science, 89(12), 2743–2750. https://doi.org/https://doi.org/10.3382/ps.2010-00902

The influences of the on-farm use of a heat exchanger (HE) for transferring the thermal energy of ventilated air stream to the fresh air inlet stream in several broiler houses have been investigated from energetic and environmental perspectives.

- According to the farmers' declarations, the use of HE resulted in a more uniform distributed temperature and air circulation, which consequently improved litter quality and uniform spread of broilers.

- Except in three farms, CO2 emission rate was decreased due to HE use.

Waste Heat Recovery Applied to a Tractor Engine (Danel et al., 2015)[10][edit | edit source]

Danel, Q., Périlhon, C., Lacour, S., Punov, P., & Danlos, A. (2015). "Waste Heat Recovery Applied to a Tractor Engine". Energy Procedia, 74, 331–343. https://doi.org/https://doi.org/10.1016/j.egypro.2015.07.622

Danel et al. implemented a thermodynamic and heat transfer model for waste heat recovery of a tractor engine exhaust gases, employing the Rankine cycle with three different working fluids (water, ethanol, R245fa). The temperature range of exhaust gases was 300 to 500 °C.

- It was concluded that R245fa is not suitable for WHR of this temperature range.

- Considering the effects of heat exchanger surface area and the engine load, it was found that ethanol is preferable for low load, and water is proper for high load operations.

- All in all, water presented a better performance for the whole operating range.

Reuse of wasted thermal energy in power plants for agricultural crops by means of multi-agent approach (González-Briones et al., 2018)[11][edit | edit source]

González-Briones, A., Chamoso, P., Prieto, J., Corchado, J. M., & Yoe, H. (2018). "Reuse of wasted thermal energy in power plants for agricultural crops by means of multi-agent approach". 2018 International Conference on Smart Energy Systems and Technologies (SEST), 1–6. https://doi.org/10.1109/SEST.2018.8495867

In this article, the temperature distribution of four 300 m2 greenhouses under the influence of a solar-assisted CHP (Combined Heating and Power)-based system of WHR from power plants has been modeled using the AI techniques.

- MAS has provided a simple way to know the demands of each greenhouse (temperature, humidity, solar radiation, etc.) using wireless sensors network that gathers useful data from greenhouses and the CHP system.

- With the aid of MAS, it was conveniently possible to provide the required amount of energy for the optimal growth of crops.

- Using the CHP system, they could reduce the average energy consumption rate of four greenhouses by 30.68 %.

CFD analysis of greenhouse heating using flue gas and hot water heat sink pipe networks (Dhiman et al., 2019)[12][edit | edit source]

Dhiman, M., Sethi, V. P., Singh, B., & Sharma, A. (2019). "CFD analysis of greenhouse heating using flue gas and hot water heat sink pipe networks". Computers and Electronics in Agriculture, 163, 104853. https://doi.org/https://doi.org/10.1016/j.compag.2019.104853

The waste heat of a combustor was led to a 100 m2 greenhouse in India, and the process has been modeled and validated based on the experimental results.

- The heat released through the radiation and convection was modeled, and the effect of incident solar radiation was not considered.

- CFD analysis revealed that the use of both flue gas heat sink pipe network (FGHSPN) harvesting waste heat of flue gas at 350 °C and hot water heat sink pipe network (HWHSPN) receiving hot water at 65 °C could provide 13.38 kW thermal energy for the greenhouse temperature rise up to 10.35 °C above the ambient temperature.

- CFD analysis has an RMSE of 1% with the experimental investigations and the RMSE of 1.5% with respect to the heat transfer modeling results.

Characterization of an Air-to-Air Heat Exchanger for Manure Belt Drying Ventilation in an Aviary Laying Hen House (Goselink & Ramirez, 2019)[13][edit | edit source]

Goselink, Y. S. M., & Ramirez, B. C. (2019). "Characterization of an Air-to-Air Heat Exchanger for Manure Belt Drying Ventilation in an Aviary Laying Hen House". Journal of Applied Poultry Research, 28(4), 1359–1369. https://doi.org/https://doi.org/10.3382/japr/pfz075

Temperature, relative humidity, ammonia, and manure dry matter content of an aviary laying hen house have been evaluated under the effect of employing an air-to-air heat exchanger in order to recover the waste heat of outgoing air and transfer it to input fresh air. This investigation has been carried out for four weeks, and the results of the 1st scenario (with heat recovery ventilation (HRV)) and the 2nd scenario (without HRV) have been compared with each other.

- The overall indoor mean temperature with HRV became warmer (23.1 °C ± 0.5 °C) than that without HRV (22.2 °C ± 1.2 °C).

- The daily average temperature range with HRV was smaller (1.8 °C ± 0.7 °C) compared to that without HRV (3.1 °C ± 1.1 °C).

- In all circumstances, average manure dry matter was greater with HRV than the case without HRV.

- In all conditions, NH3 emissions with HRV were less than that without HRV.

Application of SOFC for Power Supply of Remote Agricultural Enterprises (Sosnina et al., 2020)[14][edit | edit source]

Sosnina, E. N., Shalukho, A. V, & Veselov, L. E. (2020). "Application of SOFC for Power Supply of Remote Agricultural Enterprises". 2020 International Conference on Electrotechnical Complexes and Systems (ICOECS), 1–6. https://doi.org/10.1109/ICOECS50468.2020.9278478

This work aimed at implementing the solid oxide fuel cell (SOFC) fueled by biogas that came from the agricultural wastes (crop residues and animal husbandry) in order to provide excess electricity to the centralized electrical grid while covering the electrical and heating demands of a livestock complex. The cost analysis and optimization have also been conducted on this proposal.

- Five SOFC systems with a range of power capacities from 100 to 500 kW have been studied.

- None of the introduced SOFCs could meet all the heating demands of the livestock complex. However, the 5th one could compensate for more than half of the thermal load that was previously provided by a coal-fired boiler.

- The dependence function of the overall costs at the nominal SOFC capacity was non-linear.

- The minimum value of overall costs was achievable by employing both 1st (with the lowest capacity) and the 5th (with the highest capacity) SOFC alternatives.

Parametric analysis on the low temperature wet air waste heat recovery through an organic Rankine cycle (Yue et al., 2020)[15][edit | edit source]

Yue, C., Tong, L., & Zhang, S. (2020). "Parametric analysis on the low temperature wet air waste heat recovery through an organic Rankine cycle". Heat and Mass Transfer, 56(8), 2333–2343. https://doi.org/10.1007/s00231-020-02862-5

Chen Yue et al. conducted a thermodynamic and heat and mass transfer modeling on the application of ORC in waste heat recovery of air used for wet farm products drying. In this proposal, the bottom organic Rankine cycle absorbed the low-temperature thermal energy of wet air, passing through the drying chamber, and produced electrical power. The impacts of variation of different parameters have been studied in this article.

- Both the energy-saving efficiency and moisture extraction ratio have reached their maximum values at the lower evaporating pressures.

- The dew point temperature of humid air leaving the drying chamber was the most effective parameter compared to minimal heat transfer temperature difference and drying chamber outlet temperature.

- Increasing the dew point temperature of humid air leaving the drying chamber was the most promising method to enhance both the energy-saving efficiency and moisture extraction ratio.

Taking the results of the previous studies into consideration, it is obvious that significant advancements in the investigations of scientists have taken place. Early studies were merely on feasibility analysis of waste heat recovery applications in agricultural fields and livestock complexes. Although they had conducted experimental investigations on their proposals, the absence of mathematical modeling validated based on the experimental results was indisputable. Recent studies, however, have recommended novel WHR strategies/systems with implementing optimization, CFD simulation, and AI platforms. Nevertheless, taking further steps in this literature review and accordingly suggesting novel ideas for agricultural uses of WHR (with a special focus on greenhouse applications) with the aim of addressing the aforementioned challenges of low-temperature waste heat recovery is highly required.

1.4. Waste heat recovery applications in Greenhouses[edit | edit source]

Generally, energy plays a crucial role in meeting the greenhouses demands, and the energy costs are in the 2nd rank of all the costs related to greenhouse design and establishment. It should also be noted that about 85% of energy use in a greenhouse is attributed to heating. Thus, waste heat represents an important opportunity for greenhouse thermal energy supply, especially in cold regions (Denzer et al., n.d.)[16].

The major requirements for a greenhouse building are a piece of land located in a suitable place relative to markets, construction and building materials, insulation materials, piping materials, utilities (water and electricity), and heating supply equipment. It is crystal clear that greenhouse design is a complicated exercise involving economic experts, along with agricultural, mechanical, electrical, architectural, and computer engineers. Therefore, in order to design and develop an efficient heat recovery system for greenhouses, comprehensive studies must be conducted by technical scientists and engineers.

The economic benefits of waste heat utilization in a greenhouse were elaborated by Helgeson et al. (Helgeson et al., 1986)[17]. They revealed that the industrial waste hot water could save from 29,670$ to 95,800$ in 1981 prices compared to the conventional heating system.

Thermal Performance of an Oil Engine Driven Heat Pump for Greenhouse Heating (Kozai, 1986)[18][edit | edit source]

Kozai, T. (1986). "Thermal performance of an oil engine driven heat pump for greenhouse heating". Journal of Agricultural Engineering Research, 35(1), 25–37. https://doi.org/https://doi.org/10.1016/0021-8634(86)90027-2

The heating demands of a greenhouse has been provided indirectly by a heat pump (75 percents), and the engine's coolant water and the exhaust gases (25 percents). The engine operated at 1200-1800 rpm.

Waste-to-energy based greenhouse heating: exploring viability conditions through optimisation models (Chinese et al., 2005)[19][edit | edit source]

Chinese, D., Meneghetti, A., & Nardin, G. (2005). "Waste-to-energy based greenhouse heating: exploring viability conditions through optimisation models". Renewable Energy, 30(10), 1573–1586. https://doi.org/https://doi.org/10.1016/j.renene.2004.11.008

A 6000 m2 greenhouse was heated with the waste heat of a waste-to-energy (WTE) plant in North-Eastern Italy. The floor heating system of the greenhouse has also been optimized.

- Design and management elements of the floor heating unit were extractable from the optimization results.

- For the WTE plant's heat price of 0.020 €/kWh, the maximum value of 140000 € was deducted for the ambient temperatures of 25 °C and 20 °C, respectively for day and night.

- Needless to say, increasing the greenhouse size caused to the savings in fuel oil consumption rate, which led to a reduction in the greenhouse gas emissions compared to the traditional greenhouses.

Environmental and economic assessment of a greenhouse waste heat exchange (Andrews & Pearce, 2011)[20][edit | edit source]

Andrews, R., & Pearce, J. M. (2011). "Environmental and economic assessment of a greenhouse waste heat exchange". Journal of Cleaner Production, 19(13), 1446–1454. https://doi.org/https://doi.org/10.1016/j.jclepro.2011.04.016

The economic feasibility of operating a greenhouse with the waste heat of a flat glass manufacturing plant was assessed by the authors. and the performance of this greenhouse was compared with the conventional greenhouse heated by natural gas. It was considered that their basic costs were equal.

- A 3.9 acre greenhouse with a annual yield of 735 t of tomatoes could be supplied by the waste heat of the manufacturing plant.

- In most cases, the net present value (NPV) of waste heat greenhouse was lower than the natural gas greenhouse.

Alternative heat rejection methods for power plants (Leffler et al., 2012)[21][edit | edit source]

Leffler, R. A., Bradshaw, C. R., Groll, E. A., & Garimella, S. V. (2012). "Alternative heat rejection methods for power plants". Applied Energy, 92, 17–25. https://doi.org/https://doi.org/10.1016/j.apenergy.2011.10.023

Five WHR alternatives (cooling canals, open-water algae bioreactors, wintertime greenhouse heating, spray ponds, and modified solar updraft towers) have been presented and also applied for a coal-fired power generation sector in the Midwestern U.S.

- The modified solar updraft tower, cooling canal, algae bioreactor pond, and greenhouse require a large land area.

- The modified solar updraft towers, algae bioreactors, and greenhouse could provide a useful secondary product.

- Greenhouse heating is viable only in the winter or in extreme northern climates.

- Except for the cooling canal, the other four alternatives' water usage was less than the baseline capacity of the power plant's cooling tower.

Energy analysis of fuel cell system for commercial greenhouse application – A feasibility study (Vadiee et al., 2015)[22][edit | edit source]

Vadiee, A., Yaghoubi, M., Sardella, M., & Farjam, P. (2015). "Energy analysis of fuel cell system for commercial greenhouse application – A feasibility study". Energy Conversion and Management, 89, 925–932. https://doi.org/https://doi.org/10.1016/j.enconman.2014.09.073

A hydrogen-fueled proton exchange membrane fuel cell (PEMFC) has been designed and evaluated thermodynamically to calculate the amount of power and thermal energy it can provide for a 1000 m2 commercial greenhouse in Sweden with an annual heating demand of 117 kWh/m2.

- The 3 kW PEMFC could afford 10% and 26% of the thermal and electricity demands of the greenhouse, respectively.

- The 11.6 kW PEMFC was able to supply 40% and 100% of the thermal and electricity demands of the greenhouse, respectively.

- The use of a PCM thermal energy storage system was recommended.

The Bubble-Greenhouse: A holistic sustainable approach to small-scale water desalination in remote regions (Schmack et al., 2015)[23][edit | edit source]

Schmack, M., Ho, G., & Anda, M. (2015). "The Bubble-Greenhouse: A holistic sustainable approach to small-scale water desalination in remote regions". Desalination, 365, 250–260. https://doi.org/https://doi.org/10.1016/j.desal.2015.03.021

The concept of the bubble-greenhouse, in which a humidifying-dehumidifying (HDH) desalination system is employed for water and thermal energy supply, has been demonstrated and discussed. In this concept, the oil stream (heated by solar energy) evaporates the saline water in remote areas, which humidifies the air stream. On the other hand, the humid air becomes cooled (to 35 °C) by a cool oil stream, thereby condensing its vapor. The warm humid air is then directed to the greenhouse.

- The electricity consumption rate of regenerative air blowers must be considered. It was recommended to use the parallel blowers (each for one bubble module).

- Avoidance of thermal gradient due to the eliminating the vapor injecting system in the greenhouse could make it needless to use ventilation, which leads to a significant reduction in plants' transpiration and water consumption.

- In order to compensate for the CO2 level in a non-ventilated greenhouse, a backup greenhouse waste incinerator would be needed. In another case, the exhaust gas streams of other industrial sectors could provide the CO2 supply.

- The thermal desalination system would be a more economical option than membrane processes using electricity.

A Techno-economic Model for Heating of a Greenhouse Site Using Waste Heat (Başak & Sevilgen, 2016)[24][edit | edit source]

Başak, M. Z., & Sevilgen, S. H. (2016). "A Techno-economic Model for Heating of a Greenhouse Site Using Waste Heat". Arabian Journal for Science and Engineering, 41(5), 1895–1905. https://doi.org/10.1007/s13369-015-2009-y

The bleeding steam drawn from a power plant in Turkey has been transferred to the greenhouse site using a distribution line composed of pre-insulated pipes. A techno-economic model has been developed for the mentioned greenhouse.

- 88% of the greenhouse's annual costs were attributed to its heating costs.

- The most critical parameter affecting the greenhouse's costs was the inside temperature, especially during the night.

Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems (Yu & Nam, 2016)[25][edit | edit source]

Yu, M. G., & Nam, Y. (2016). "Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems". Energies, 9(2). https://doi.org/10.3390/en9020112

The feasibility of using power plant waste heat in three different large scale horticulture plants was studied.

- It was concluded that about 7.4-20% of power plants' waste energy can provide the heating demands of these areas.

- By replacing the diesel boiler with the WHR system, about the 83% of annual operating costs would be reduced.

- The payback periods of these systems were estimated to be 2-3 years.

STUDY OF THE ENERGETIC AND THE ECONOMIC FEASIBILITY OF A HEATING AGRICULTURAL GREENHOUSE USING INDUSTRIAL WASTE-HEAT AT LOW TEMPERATURES (Fguiri et al., 2017)[26][edit | edit source]

Fguiri, A., Fatnassi, H., Jeday, M.-R., & Marvillet, C. (2017). "STUDY OF THE ENERGETIC AND THE ECONOMIC FEASIBILITY OF A HEATING AGRICULTURAL GREENHOUSE USING INDUSTRIAL WASTE-HEAT AT LOW TEMPERATURES". 25(4).

It was a project conducted by Fguiri et al to establish a 1 ha greenhouse of tomato and cucumber heated by the waste heat of the industrial unit of di-ammonium phosphate production.

- The net present value (NPV) for the tomato greenhouse was calculated to be 1127327 $, and also for the cucumber greenhouse was 1293427 $.

- This proposal could save 746 teqCO2 (equal to the consumption of 1800 barrels of crude oil) compared to the basic case.

Biogas production from energy crops in northern Greece: economics of electricity generation associated with heat recovery in a greenhouse (Markou et al., 2017)[27][edit | edit source]

Markou, G., Brulé, M., Balafoutis, A., Kornaros, M., Georgakakis, D., & Papadakis, G. (2017). "Biogas production from energy crops in northern Greece: economics of electricity generation associated with heat recovery in a greenhouse". Clean Technologies and Environmental Policy, 19(4), 1147–1167. https://doi.org/10.1007/s10098-016-1314-9

The economic feasibility of the cultivation of energy crops (triticale, maize, alfalfa, sunflower, clover, barley, and wheat) for the anaerobic digestion (AD) in Greece has been evaluated. A CHP concept has also been considered to use the produced biogas from AD and provide the heating demand of a vegetable (tomato) greenhouse while selling the electricity to the grid. A detailed economic simulation has been developed for each section (cultivation plant, AD, and greenhouse).

- It was revealed that the methane yields of maize and triticale were higher than the other crops. They also had the lowest energy production costs.

- Considering the electricity and vegetables sale income, the total income from the AD of maize was 1,875,000 €/year, followed by triticale with the total income of 1,660,000 €/year. About 17-18% of these incomes came from the contribution of greenhouses to the system.

- An agricultural surface larger than 500 ha or a biogas AD plant larger than 1000 m2 is needed for this proposal.

- The average annual thermal energy recovery rate of the CHP system was 40%.

Possibilities of Using Industrial Waste Heat for Heating Greenhouses in Northern Greece (Vourdoubas, 2018)[28][edit | edit source]

Vourdoubas, J. (2018). "Possibilities of Using Industrial Waste Heat for Heating Greenhouses" in. 10(4), 116–123. https://doi.org/10.5539/jas.v10n4p116

The techno-economic feasibility of the utilization of waste heat of the lignite-fired power plants has been investigated for industrial-agricultural symbiosis purposes. Previously, the rejected heat from lignite-fired power plants was used for district heating. The greenhouse inlet temperature of hot water was about 50-55 °C, which was provided through well-insulated plastic pipes placed on the ground to heat soil and air.

- For the temperature drop of 20 °C for heating water, the heating load of the greenhouse would be 1700 kWh per hectare, and the flow rate of heating water would be 73.18 m3/h per hectare. This is while, for district heating strategy, the values of these indicators were 140 MWh and 2300 m3/h, respectively.

- Warm water use in the greenhouse was more economical than both the district heating approach and conventional fossil-fueled heating systems.

GreenVMAS: Virtual Organization Based Platform for Heating Greenhouses Using Waste Energy from Power Plants (González-Briones, Chamoso, Yoe, et al., 2018)[29][edit | edit source]

González-Briones, A., Chamoso, P., Yoe, H., & Corchado, J. M. (2018). "GreenVMAS: Virtual Organization Based Platform for Heating Greenhouses Using Waste Energy from Power Plants". Sensors, 18(3). https://doi.org/10.3390/s18030861

The artificial neural network (ANN)-based virtual MAS has been developed for six 300 m2 similar greenhouses to maintain their performances balanced and also optimal while they are enjoying the waste heat of a nuclear power plant. They could monitor and control the inside temperature, state of the crops, and valves opening and closing.

- The authors concluded that the VMAS is essential for saving energy and money and lowering CO2 emissions.

- The energy consumption rate decreased by 23.79%, 39.40%, and 41.46%, respectively, in summer, autumn, and winter.

Net-zero energy and energy sharing potential of retail - Greenhouse complex (Syed & Hachem, 2019)[30][edit | edit source]

Syed, A. M., & Hachem, C. (2019). "Net-zero energy design and energy sharing potential of Retail - Greenhouse complex". Journal of Building Engineering, 24, 100736. https://doi.org/https://doi.org/10.1016/j.jobe.2019.100736

In order to achieve the net-zero energy goals, A waste heat exchange system has been designed between two buildings of the retail-greenhouse complex, and a solar photovoltaic system have been considered to improve the energy efficiency of the system.

- The total energy consumption rate of retail and greenhouse was 730 MWh and 120 MWh, respectively. Of the overall energy consumed by the complex, 35% was attributed to heating, and 32% was for refrigeration.

- After the optimization, a significant reduction in energy consumption rate (especially in plug and refrigeration loads) was seen. Hence, 27% of energy could be saved.

- The excess produced power in the spring and summer was sold to the grid. However, in the late fall and winter months, they had to buy electricity from the grid.

- About 130 MWh of waste heat of the refrigerator's condenser was recovered for space and water heating purposes in the greenhouse.

Sethi and Sharma (Sethi & Sharma, 2008)[31] presented some useful thermal storage technologies for waste heat storing and releasing in/to greenhouses. Thermal energy storage systems include water storage (plastic bags, ground tubes, and water tanks), rock bed thermal storage, and PCM storage.

Combined Cooling Heating and Power systems in greenhouses. Grassroots and retrofit design (Tataraki et al., 2019)[edit | edit source]

Tataraki, K. G., Kavvadias, K. C., & Maroulis, Z. B. (2019). "Combined cooling heating and power systems in greenhouses. Grassroots and retrofit design". Energy, 189, 116283. https://doi.org/https://doi.org/10.1016/j.energy.2019.116283

The economic advantages of a CHP and CCHP (Combined Cooling, Heating, Power) systems' deployment for supplying the thermal requirements of greenhouses have been studied. The results have been validated based on the operating characteristics of three greenhouses located in Northern Greece. The main cultivating products were tomato and cucumber.

- The CHP design was more economical than the conventional natural gas boiler.

- The meteorological conditions of each location had a significant effect on the thermal performance of the greenhouses.

- The energy-saving ratio was higher for tomato and northern locations.

- The active cooling system of the absorption refrigerator was an economical solution, even though its investment risks and design complexity are high.

Energy efficiency optimization of the waste heat recovery system with embedded phase change materials in greenhouses: A thermo-economic-environmental study (S.-R. Yan et al., 2020)[32][edit | edit source]

Yan, S.-R., Fazilati, M. A., Samani, N., Ghasemi, H. R., Toghraie, D., Nguyen, Q., & Karimipour, A. (2020). "Energy efficiency optimization of the waste heat recovery system with embedded phase change materials in greenhouses: A thermo-economic-environmental study". Journal of Energy Storage, 30, 101445. https://doi.org/https://doi.org/10.1016/j.est.2020.101445

The effect of waste heat recovery system (HRS) and embedded phase change material (PCM) integration to the conventional fossil fuel heater in a greenhouse in Iran has been studied experimentally from the thermodynamic and economic viewpoints. HRS is a box through which the heater's exhaust gas passes to heat the fresh ventilation air entering the greenhouse. PCM was also embedded into this box to study the effects of its presence.

- The energy efficiency of the heating system with HRS and with HRS+PCM has been improved by 33% and 140%, respectively, compared to that of the conventional gas burner.

- The exergy efficiency of the heating system with HRS and with HRS+PCM has been enhanced by 127% and 263%, respectively, compared to that of the conventional gas burner.

- The inside temperature of the greenhouse has been increased by 0.7 °C and 3 °C, respectively, considering HRS and HRS+PCM.

- The natural gas consumption rate has been decreased by 19% and 48%, respectively, for the systems integrated with HRS and HRS+PCM.

- The payback period was estimated for the systems integrated with HRS and HRS+PCM, respectively, 3 and 4 months.

Energy cost and efficiency analysis of greenhouse heating system enhancement using phase change material: An experimental study (S. Yan et al., 2021)[33][edit | edit source]

Yan, S., Fazilati, M. A., Toghraie, D., Khalili, M., & Karimipour, A. (2021). "Energy cost and efficiency analysis of greenhouse heating system enhancement using phase change material: An experimental study". Renewable Energy, 170, 133–140. https://doi.org/https://doi.org/10.1016/j.renene.2021.01.081

In a similar article to the previous one in 2020, Shurong Yan et al. compared the energetic and economic consequences of two different strategies in the application of warm air provided by the HRS+PCM waste heat recovery system: 1) For direct space heating of greenhouse 2) For preheating of inlet air of gas burner. They found that the second strategy has better results in terms of energy efficiency.

Data center heated greenhouses, a matter for enhanced food self-sufficiency in sub-arctic regions (Ljungqvist et al., 2021)[34][edit | edit source]

Ljungqvist, H. M., Mattsson, L., Risberg, M., & Vesterlund, M. (2021). "Data center heated greenhouses, a matter for enhanced food self-sufficiency in sub-arctic regions". Energy, 215, 119169. https://doi.org/https://doi.org/10.1016/j.energy.2020.119169

The performance of two 2000 and 10000 m2 greenhouses has been simulated under two scenarios (partial-year production without grow lights and full-load production with grow lights) for the aim of enhancing the food self-sufficiency by utilizing the waste heat of a 1 MW data center in Northern Sweden.

- This was a cost-effective strategy for food self-sufficiency in Northern Sweden.

- The larger greenhouse was a better alternative than the smaller one since it could benefit from more heat recovered and produce cheaper tomatoes (its cost under partial and full-year production was 2.02 and 1.80 €/kg for small scale and 1.88 and 1.49 €/kg for large scale greenhouse).

- From the sustainability perspective, the small-scale greenhouse was a better choice since only 10.3% and 2.1% (in partial-year and full-year scenarios) of its heating demand must be provided by an additional heat source.

- The full-year production had a lower cost price.

Building-integrated greenhouses raise energy co-benefits through active ventilation systems (Muñoz-Liesa et al., 2022)[35][edit | edit source]

Muñoz-Liesa, J., Royapoor, M., Cuerva, E., Gassó-Domingo, S., Gabarrell, X., & Josa, A. (2022). "Building-integrated greenhouses raise energy co-benefits through active ventilation systems". Building and Environment, 208, 108585. https://doi.org/https://doi.org/10.1016/j.buildenv.2021.108585

The synergetic influence of airflow exchanging of a rooftop greenhouse (iRTG) and an office building HVAC system in a Mediterranean climate has been studied under three energy scenarios: 1) building's exhaust air energy recovery by a greenhouse. 2) greenhouse's excess air utilization by building. 3) Combination of scenarios 1 and 2.

- 143.3 kWh/m2 per year in winter and 54.8 kWh/m2 per year of greenhouse's thermal demand in summer could be met by building.

- In scenario 2, 205.2 kWh/m2 per year and 335.3 kWh/m2 per year (respectively for 1.59 and 3.16 ac/h of the air exchange rate) of thermal energy in offices and Labs could be provided by the greenhouse.

- For the maximum air exchange rate (3.16 ac/h), 658.8 kWh/m2 was the sensible heat gain per year, whose the equivalent electricity value was 198.2 kWh/m2 per year.

- ↑ 1.0 1.1 Jouhara, H., Khordehgah, N., Almahmoud, S., Delpech, B., Chauhan, A., & Tassou, S. A. (2018). Waste heat recovery technologies and applications. Thermal Science and Engineering Progress, 6, 268–289. https://doi.org/https://doi.org/10.1016/j.tsep.2018.04.017

- ↑ 2.0 2.1 2.2 Johnson, I., Choate, W. T., & Davidson, A. (2008). Waste Heat Recovery. Technology and Opportunities in U.S. Industry. https://doi.org/10.2172/1218716

- ↑ Thekdi, A., & Nimbalkar, S. U. (2015). Industrial Waste Heat Recovery - Potential Applications, Available Technologies and Crosscutting R&D Opportunities. https://doi.org/10.2172/1185778

- ↑ Brückner, S., Liu, S., Miró, L., Radspieler, M., Cabeza, L. F., & Lävemann, E. (2015). Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Applied Energy, 151, 157–167. https://doi.org/https://doi.org/10.1016/j.apenergy.2015.01.147

- ↑ Haddad, C., Périlhon, C., Danlos, A., François, M.-X., & Descombes, G. (2014). Some Efficient Solutions to Recover Low and Medium Waste Heat: Competitiveness of the Thermoacoustic Technology. Energy Procedia, 50, 1056–1069. https://doi.org/https://doi.org/10.1016/j.egypro.2014.06.125

- ↑ 6.0 6.1 Yarosh, M. M., Nichols, B. L., Hirst, E. A., Michel, J. W., & Yee, W. C. (1972). Agricultural and aquacultural uses of waste heat. Other Information: UNCL. Orig. Receipt Date: 31-DEC-72. https://doi.org/10.2172/4675611

- ↑ Shupe, W. L., & Whitehead, W. K. (1979). Heat recovery from poultry processing scald water. Journal of Agricultural Engineering Research, 24(3), 325–330. https://doi.org/https://doi.org/10.1016/0021-8634(79)90074-X

- ↑ Hughes, D. F. (1984). Extraction of energy from an aerobic farm waste lagoon. Journal of Agricultural Engineering Research, 29(2), 133–139. https://doi.org/https://doi.org/10.1016/0021-8634(84)90067-2

- ↑ Bokkers, E. A. M., van Zanten, H. H. E., & van den Brand, H. (2010). Field study on effects of a heat exchanger on broiler performance, energy use, and calculated carbon dioxide emission at commercial broiler farms, and the experiences of farmers using a heat exchanger. Poultry Science, 89(12), 2743–2750. https://doi.org/https://doi.org/10.3382/ps.2010-00902

- ↑ Danel, Q., Périlhon, C., Lacour, S., Punov, P., & Danlos, A. (2015). Waste Heat Recovery Applied to a Tractor Engine. Energy Procedia, 74, 331–343. https://doi.org/https://doi.org/10.1016/j.egypro.2015.07.622

- ↑ González-Briones, A., Chamoso, P., Prieto, J., Corchado, J. M., & Yoe, H. (2018). Reuse of wasted thermal energy in power plants for agricultural crops by means of multi-agent approach. 2018 International Conference on Smart Energy Systems and Technologies (SEST), 1–6. https://doi.org/10.1109/SEST.2018.8495867

- ↑ Dhiman, M., Sethi, V. P., Singh, B., & Sharma, A. (2019). CFD analysis of greenhouse heating using flue gas and hot water heat sink pipe networks. Computers and Electronics in Agriculture, 163, 104853. https://doi.org/https://doi.org/10.1016/j.compag.2019.104853

- ↑ Goselink, Y. S. M., & Ramirez, B. C. (2019). Characterization of an Air-to-Air Heat Exchanger for Manure Belt Drying Ventilation in an Aviary Laying Hen House. Journal of Applied Poultry Research, 28(4), 1359–1369. https://doi.org/https://doi.org/10.3382/japr/pfz075

- ↑ Sosnina, E. N., Shalukho, A. V, & Veselov, L. E. (2020). Application of SOFC for Power Supply of Remote Agricultural Enterprises. 2020 International Conference on Electrotechnical Complexes and Systems (ICOECS), 1–6. https://doi.org/10.1109/ICOECS50468.2020.9278478

- ↑ Yue, C., Tong, L., & Zhang, S. (2020). Parametric analysis on the low temperature wet air waste heat recovery through an organic Rankine cycle. Heat and Mass Transfer, 56(8), 2333–2343. https://doi.org/10.1007/s00231-020-02862-5

- ↑ Denzer, A., Wang, L., Thomas, Y., & McMorrow, G. (n.d.). Greenhouse Design with Waste Heat: Principles and Practices. In AEI 2017 (pp. 440–455). https://doi.org/10.1061/9780784480502.037

- ↑ Helgeson, D. L., Petry, T. A., & Erlandson, G. W. (1986). An Economic Analysis of Operating a Simulated Two-Acre Greenhouse Utilizing Waste-Water Heat. North Central Journal of Agricultural Economics, 8(1), 123–134. https://doi.org/10.2307/1349087

- ↑ Kozai, T. (1986). Thermal performance of an oil engine driven heat pump for greenhouse heating. Journal of Agricultural Engineering Research, 35(1), 25–37. https://doi.org/https://doi.org/10.1016/0021-8634(86)90027-2

- ↑ Chinese, D., Meneghetti, A., & Nardin, G. (2005). Waste-to-energy based greenhouse heating: exploring viability conditions through optimisation models. Renewable Energy, 30(10), 1573–1586. https://doi.org/https://doi.org/10.1016/j.renene.2004.11.008

- ↑ Andrews, R., & Pearce, J. M. (2011). Environmental and economic assessment of a greenhouse waste heat exchange. Journal of Cleaner Production, 19(13), 1446–1454. https://doi.org/https://doi.org/10.1016/j.jclepro.2011.04.016

- ↑ Leffler, R. A., Bradshaw, C. R., Groll, E. A., & Garimella, S. V. (2012). Alternative heat rejection methods for power plants. Applied Energy, 92, 17–25. https://doi.org/https://doi.org/10.1016/j.apenergy.2011.10.023

- ↑ Vadiee, A., Yaghoubi, M., Sardella, M., & Farjam, P. (2015). Energy analysis of fuel cell system for commercial greenhouse application – A feasibility study. Energy Conversion and Management, 89, 925–932. https://doi.org/https://doi.org/10.1016/j.enconman.2014.09.073

- ↑ Schmack, M., Ho, G., & Anda, M. (2015). The Bubble-Greenhouse: A holistic sustainable approach to small-scale water desalination in remote regions. Desalination, 365, 250–260. https://doi.org/https://doi.org/10.1016/j.desal.2015.03.021

- ↑ Başak, M. Z., & Sevilgen, S. H. (2016). A Techno-economic Model for Heating of a Greenhouse Site Using Waste Heat. Arabian Journal for Science and Engineering, 41(5), 1895–1905. https://doi.org/10.1007/s13369-015-2009-y

- ↑ Yu, M. G., & Nam, Y. (2016). Feasibility Assessment of Using Power Plant Waste Heat in Large Scale Horticulture Facility Energy Supply Systems. Energies, 9(2). https://doi.org/10.3390/en9020112

- ↑ Fguiri, A., Fatnassi, H., Jeday, M.-R., & Marvillet, C. (2017). STUDY OF THE ENERGETIC AND THE ECONOMIC FEASIBILITY OF A HEATING AGRICULTURAL GREENHOUSE USING INDUSTRIAL WASTE-HEAT AT LOW TEMPERATURES. 25(4).

- ↑ Markou, G., Brulé, M., Balafoutis, A., Kornaros, M., Georgakakis, D., & Papadakis, G. (2017). Biogas production from energy crops in northern Greece: economics of electricity generation associated with heat recovery in a greenhouse. Clean Technologies and Environmental Policy, 19(4), 1147–1167. https://doi.org/10.1007/s10098-016-1314-9

- ↑ Vourdoubas, J. (2018). Possibilities of Using Industrial Waste Heat for Heating Greenhouses in. 10(4), 116–123. https://doi.org/10.5539/jas.v10n4p116

- ↑ González-Briones, A., Chamoso, P., Yoe, H., & Corchado, J. M. (2018). GreenVMAS: Virtual Organization Based Platform for Heating Greenhouses Using Waste Energy from Power Plants. Sensors, 18(3). https://doi.org/10.3390/s18030861

- ↑ Syed, A. M., & Hachem, C. (2019). Net-zero energy design and energy sharing potential of Retail - Greenhouse complex. Journal of Building Engineering, 24, 100736. https://doi.org/https://doi.org/10.1016/j.jobe.2019.100736

- ↑ Sethi, V. P., & Sharma, S. K. (2008). Survey and evaluation of heating technologies for worldwide agricultural greenhouse applications. Solar Energy, 82(9), 832–859. https://doi.org/https://doi.org/10.1016/j.solener.2008.02.010

- ↑ Yan, S.-R., Fazilati, M. A., Samani, N., Ghasemi, H. R., Toghraie, D., Nguyen, Q., & Karimipour, A. (2020). Energy efficiency optimization of the waste heat recovery system with embedded phase change materials in greenhouses: A thermo-economic-environmental study. Journal of Energy Storage, 30, 101445. https://doi.org/https://doi.org/10.1016/j.est.2020.101445

- ↑ Yan, S., Fazilati, M. A., Toghraie, D., Khalili, M., & Karimipour, A. (2021). Energy cost and efficiency analysis of greenhouse heating system enhancement using phase change material: An experimental study. Renewable Energy, 170, 133–140. https://doi.org/https://doi.org/10.1016/j.renene.2021.01.081

- ↑ Ljungqvist, H. M., Mattsson, L., Risberg, M., & Vesterlund, M. (2021). Data center heated greenhouses, a matter for enhanced food self-sufficiency in sub-arctic regions. Energy, 215, 119169. https://doi.org/https://doi.org/10.1016/j.energy.2020.119169

- ↑ Muñoz-Liesa, J., Royapoor, M., Cuerva, E., Gassó-Domingo, S., Gabarrell, X., & Josa, A. (2022). Building-integrated greenhouses raise energy co-benefits through active ventilation systems. Building and Environment, 208, 108585. https://doi.org/https://doi.org/10.1016/j.buildenv.2021.108585