This OSAT project is the design and prototyping of a hydraulic ram pump. This pump features no motorized parts and can be left unattended for extended duration with minimal upkeep. This pump is designed to allow someone in an area with hills with a water source far away. The ram pump does have a lot of waste water compared to how much it pumps, so it is ideal to place the waste outlet into a natural occurring water source.

Bill of Materials[edit | edit source]

- Standard Pop Bottle (~$2 USD)

- Super Glue (~$5 USD)

- Knife or cutting edge to clean up print if need be

- 3D Printed Parts

Tools needed[edit | edit source]

- MOST Delta RepRap or similar RepRap 3-D printer

- Knife

Skills and knowledge needed[edit | edit source]

- Science behind pump

- No special skills or knowledge needed to assemble pump

Technical Specifications and Assembly Instructions[edit | edit source]

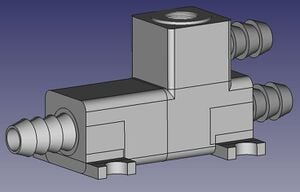

- Ram Pump Assembly

- Print time ~~18 hours

- Assembly time ~~30 min

Common Problems and Solutions[edit | edit source]

- To avoid trouble with assembly, use the knife to smooth the parts till they fit "snug".

- Highly recommended to print the adapters and restrictions at layer height of 0.3 mm

- Highly recommended to print the pump bodies at layer height of 0.2 mm

- Highly recommended to print the threads at layer height of 0.1 mm

- When using super glue, be careful not to overdue it. Too much glue can clog areas of the pump. Just keep a towel or rag handy to wipe excess glue in some areas.

- If the pump is struggling to pump water, make sure the source for the inlet is significantly higher than the pump (at least 1 meter)

Cost savings[edit | edit source]

- Material Costs total ~~$13.8 USD

- Printinf cost ~~$6.8 USD

- Resources cost ~~$7 USD

- Commercial 1" Ram Pump ~~$165 USD[1]

- Savings

- ~~$151.2 USD in savings

- ~~ 91% in savings

Benefited Internet Communities[edit | edit source]

References[edit | edit source]

Wikipedia:Bernoulli's principle