J.M.Pearce (talk | contribs) m (→See also) |

(Set shorter title-tag for SEO purposes) |

||

| (13 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:magneto.jpg|thumb]] | |||

{{MOST}} | {{MOST}} | ||

{{ | {{Source data | ||

| type = Paper | |||

= | | cite-as = Yuenyong Nilsiam, Amberlee Haselhuhn, Bas Wijnen, Paul Sanders, & Joshua M. Pearce. [http://www.mdpi.com/2075-1702/3/4/339/htm Integrated Voltage - Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer].''Machines'' '''3'''(4), 339-351 (2015). doi:10.3390/machines3040339 [https://www.academia.edu/17673716/Integrated_Voltage_Current_Monitoring_and_Control_of_Gas_Metal_Arc_Weld_Magnetic_Ball-Jointed_Open_Source_3-D_Printer open access] | ||

}} | |||

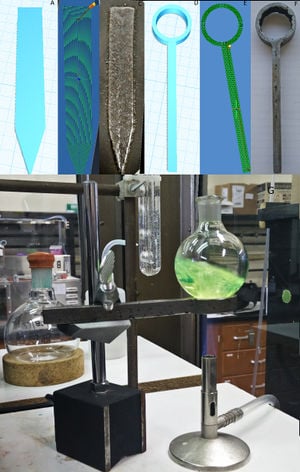

To provide process optimization of metal fabricating self-replicating rapid prototyper (RepRap) 3-D printers requires a low-cost sensor and data logger system to measure current (I) and voltage (V) of the gas metal arc welders (GMAW). This paper builds on previous open-source hardware development to provide a real-time measurement of welder I-V where the measuring circuit is connected to two analog inputs of the Arduino that is used to control the 3-D printer itself. Franklin firmware accessed through a web interface that is used to control the printer allows storing the measured values and downloading those stored readings to the user's computer. To test this custom current and voltage monitoring device this study reports on its use on an upgraded all metal RepRap during the printing of aluminum alloy (ER1100, ER4043, ER4943, ER4047, and ER5356). The voltage and current data were analyzed on a per alloy basis and also layer-by-layer in order to evaluate the device's efficacy as a monitoring device for 3-D printing and the results of the integrated design are discussed. | |||

* Full hardware source available at: https://osf.io/ytvgm/ (includes CADs, BOM and STls) | * Full hardware source available at: https://osf.io/ytvgm/ (includes CADs, BOM and STls) | ||

* Full source code for voltage and current data processing available at: [https://github.com/mtu-most/MOST-Voltage-Current-Data-Processor MOST-Voltage-Current-Data-Processor] (*.m for MATLAB or Octave) | * Full source code for voltage and current data processing available at: [https://github.com/mtu-most/MOST-Voltage-Current-Data-Processor MOST-Voltage-Current-Data-Processor] (*.m for MATLAB or Octave) | ||

* [[3D Metal Printing Slicer Plugin]] | * [[3D Metal Printing Slicer Plugin]] | ||

* [[Franklin]] firmware | * [[Franklin]] firmware | ||

* [[Slicer and process improvements for open-source GMAW-based metal 3-D printing]] | |||

{{Pearce publications notice}} | |||

{{MOST-RepRap}} | |||

== Keywords == | |||

[[3-D printing]], [[gas metal arc weld]], GMAW, metal inert gas welding, [[MIG welding]], [[power]] monitoring, [[additive manufacturing]];data logging; metal printing;[[open-source hardware]]; quality control;[[RepRap]]; welder;welding | |||

[[3-D printing]], [[gas metal arc weld]], GMAW, metal inert gas welding, [[MIG welding]], [[power]] monitoring, [[additive manufacturing]];data logging; metal printing;[[open-source hardware]]; quality control;[[RepRap]]; | |||

== See also == | |||

[[File:Metal3dp-burner.jpg|300px|right]] | |||

* [[Open-source metal 3-D printer]] | * [[Open-source metal 3-D printer]] | ||

* [[Open Source Arc Analyzer: Multi-Sensor Monitoring of Wire Arc Additive Manufacturing]] | |||

* [[Applications of Open Source GMAW-Based Metal 3-D Printing]] | |||

* [[Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing]] | * [[Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing]] | ||

* [[MOST open-source metal 3-D printer v2]] | * [[MOST open-source metal 3-D printer v2]] | ||

* [[Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing]] - how to get your print off the substrate with a hammer | * [[Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing]] - how to get your print off the substrate with a hammer | ||

* [[In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing]] | * [[In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing]] | ||

* [[Particle Swarm Optimization of Printing Parameters for Open-Source TIG-Based Metal 3D Printing]] | |||

* [[Aluminum substrate cleaning for 3-D printing:MOST]] | * [[Aluminum substrate cleaning for 3-D printing:MOST]] | ||

* [[Hypoeutectic Aluminum–Silicon Alloy Development for GMAW-Based 3-D Printing Using Wedge Castings]] | * [[Hypoeutectic Aluminum–Silicon Alloy Development for GMAW-Based 3-D Printing Using Wedge Castings]] | ||

* [[Open-source Lab]] | * [[Open-source Lab]] | ||

* [[Open source 3-D printing of OSAT]] | * [[Open source 3-D printing of OSAT]] | ||

* [[Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers ]] | * [[Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers]] | ||

* [[Environmental impacts of distributed manufacturing from 3-D printing of polymer components and products ]] | * [[Environmental impacts of distributed manufacturing from 3-D printing of polymer components and products]] | ||

* [[Building research equipment with free, open-source hardware ]] | * [[Building research equipment with free, open-source hardware]] | ||

* [http://metal2014.weblog.tudelft.nl/ Delft University of Technology - MIG+ Prusa I3] | * [http://web.archive.org/web/20181228222003/http://metal2014.weblog.tudelft.nl/ Delft University of Technology - MIG+ Prusa I3] | ||

* [http://www.weld3d.com/ Weld 3D] - 1st commercial spin off | * [http://www.weld3d.com/ Weld 3D] - 1st commercial spin off | ||

* see literature on "wire arc additive manufacturing" (WAAM) | * see literature on "wire arc additive manufacturing" (WAAM) | ||

{{Page data | |||

| title-tag = Voltage—Current Control of GMAW 3D Printer | |||

}} | |||

[[Category:3D printing]] | [[Category:3D printing]] | ||

Latest revision as of 16:03, 23 February 2024

To provide process optimization of metal fabricating self-replicating rapid prototyper (RepRap) 3-D printers requires a low-cost sensor and data logger system to measure current (I) and voltage (V) of the gas metal arc welders (GMAW). This paper builds on previous open-source hardware development to provide a real-time measurement of welder I-V where the measuring circuit is connected to two analog inputs of the Arduino that is used to control the 3-D printer itself. Franklin firmware accessed through a web interface that is used to control the printer allows storing the measured values and downloading those stored readings to the user's computer. To test this custom current and voltage monitoring device this study reports on its use on an upgraded all metal RepRap during the printing of aluminum alloy (ER1100, ER4043, ER4943, ER4047, and ER5356). The voltage and current data were analyzed on a per alloy basis and also layer-by-layer in order to evaluate the device's efficacy as a monitoring device for 3-D printing and the results of the integrated design are discussed.

- Full hardware source available at: https://osf.io/ytvgm/ (includes CADs, BOM and STls)

- Full source code for voltage and current data processing available at: MOST-Voltage-Current-Data-Processor (*.m for MATLAB or Octave)

- 3D Metal Printing Slicer Plugin

- Franklin firmware

- Slicer and process improvements for open-source GMAW-based metal 3-D printing

Keywords[edit | edit source]

3-D printing, gas metal arc weld, GMAW, metal inert gas welding, MIG welding, power monitoring, additive manufacturing;data logging; metal printing;open-source hardware; quality control;RepRap; welder;welding

See also[edit | edit source]

- Open-source metal 3-D printer

- Open Source Arc Analyzer: Multi-Sensor Monitoring of Wire Arc Additive Manufacturing

- Applications of Open Source GMAW-Based Metal 3-D Printing

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- MOST open-source metal 3-D printer v2

- Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing - how to get your print off the substrate with a hammer

- In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing

- Particle Swarm Optimization of Printing Parameters for Open-Source TIG-Based Metal 3D Printing

- Aluminum substrate cleaning for 3-D printing:MOST

- Hypoeutectic Aluminum–Silicon Alloy Development for GMAW-Based 3-D Printing Using Wedge Castings

- Open-source Lab

- Open source 3-D printing of OSAT

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Environmental impacts of distributed manufacturing from 3-D printing of polymer components and products

- Building research equipment with free, open-source hardware

- Delft University of Technology - MIG+ Prusa I3

- Weld 3D - 1st commercial spin off

- see literature on "wire arc additive manufacturing" (WAAM)