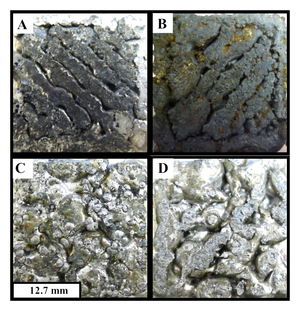

This study provides an in-depth investigation into low-cost and no-cost substrate release mechanisms that allow gas metal arc weld 3-D printed ER4043 aluminum and ER70S-6 steel parts to be removed from a reusable print substrate with minimal energy. Aluminum oxide, boron nitride, and titanium nitride coatings were evaluated as possible substrate release agents for aluminum printing. Additionally, the in situ formation of substrate release agents such as intermetallics and oxides were tested for both aluminum and steel printing. Testing was performed with a modified Charpy impact tester to remove 3-D printed metal parts from an 1100 aluminum or A36 low carbon steel print substrate to assess the impact energy required for removal. Specimen porosity was measured prior to sectioning and microstructural analysis, hardness traverses were measured across the specimens, and the elastic and shear moduli of the parts were analyzed via ultrasonic methods. All of the employed substrate release mechanisms minimized weld penetration and, in some instances, formed a brittle phase with the print substrate that allowed the specimens to be removed with minimal impact energy. These results thus provide methods with the removal of metal 3-D printed parts from print substrates with no specialized tooling or equipment conducive to distributed manufacturing.

Highlights[edit | edit source]

- In-depth investigation into low-cost and no-cost substrate release mechanisms.

- Allows gas metal arc weld 3D printed ER4043 aluminum, ER70S-6 steel removal.

- Reusable print substrate with minimal energy and no tools.

- Studied aluminum oxide, boron nitride, and titanium nitride coatings.

- In situ formation of substrate release agents such as intermetallics and oxides.

Keywords[edit | edit source]

3-D printing; additive manufacturing; aluminum; steel; in situ formation; distributed manufacturing; gas metal arc weld; GMAW; metal processing; metal inert gas welding; MIG welding; open-source; open-source electronics; open-source hardware; personal fabrication; rapid prototyping

See also[edit | edit source]

- Open-source metal 3-D printer

- MOST open-source metal 3-D printer v2

- Open Source Arc Analyzer: Multi-Sensor Monitoring of Wire Arc Additive Manufacturing

- Applications of Open Source GMAW-Based Metal 3-D Printing

- Slicer and process improvements for open-source GMAW-based metal 3-D printing

- Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing - how to get your print off the substrate with a hammer

- Aluminum substrate cleaning for 3-D printing:MOST

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer

- 3D Metal Printing Slicer Plugin

- Particle Swarm Optimization of Printing Parameters for Open-Source TIG-Based Metal 3D Printing

- Open-source Lab

- Open source 3-D printing of OSAT

- Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers

- Environmental impacts of distributed manufacturing from 3-D printing of polymer components and products

- Building research equipment with free, open-source hardware

- Delft University of Technology - MIG+ Prusa I3

- Weld 3D - 1st commercial spin off

- see literature on "wire arc additive manufacturing" (WAAM)

In the News[edit | edit source]

- Michigan Tech Opens Up Reusable Substrates for Metal 3D Printing - 3D Printing Industry

- Researchers Solve Major Issue Surrounding Metal 3D Printing With Reusable Substrates - 3D Print

- New research into gas metal arc weld 3D printing unveils easier part removal techniques - 3Ders

- Researchers solve key problem surrounding metal 3D printing - Australian Manufacturing