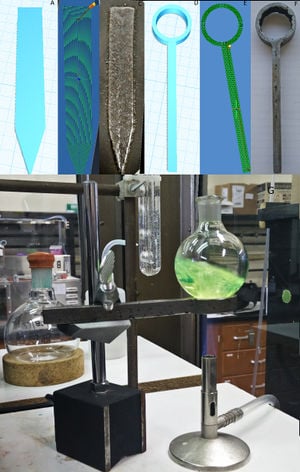

The metal 3-D printing market is currently dominated by high-end applications, which make it inaccessible for small and medium enterprises, fab labs, and individual makers who are interested in the ability to prototype and additively manufacture final products in metal. Recent progress led to low-cost open-source metal 3-D printers using a gas metal arc welding (GMAW)-based print head. This reduced the cost of metal 3-D printers into the range of desktop prosumer polymer 3-D printers. Consequent research established good material properties of metal 3-D printed parts with readily-available weld filler wire, reusable substrates, thermal and stress properties, toolpath planning, bead-width control, mechanical properties, and support for overhangs. These previous works showed that GMAW-based metal 3-D printing has a good adhesion between layers and is not porous inside the printed parts, but they did not proceed far enough to demonstrate applications. In this study, the utility of the GMAW approach to 3-D printing is investigated using a low-cost open-source metal 3-D printer and a converted Computer Numerical Control router machine to make useful parts over a range of applications including: fixing an existing part by adding a 3-D metal feature, creating a product using the substrate as part of the component, 3-D printing in high resolution of useful objects, near net objects, and making an integrated product using a combination of steel and polymer 3-D printing. The results show that GMAW-based 3-D printing is capable of distributed manufacturing of useful products for a wide variety of applications for sustainable development.

- These 3-D models as STL files can be found at https://osf.io/bbbtd

- Slicing:

- Instructions: MOST Metal Cura

- Source code: https://github.com/mtu-most/MOSTMetalCura

- original source: Ultimaker/CuraEngine (2015) https://github.com/Ultimaker/CuraEngine and Ultimaker/CuraEngine (2015) https://github.com/Ultimaker/CuraEngine

- MOST metal slicing examples https://osf.io/6u5sp/

Keywords[edit | edit source]

3-D printing, gas metal arc weld, GMAW, metal inert gas welding, MIG welding, additive manufacturing;metal printing;open-source hardware; RepRap; welder;welding; Metal 3-D printing, Low cost metal 3-D printer, Open-source metal 3-D printer, GMAW 3-D printing

See also[edit | edit source]

- Open-source metal 3-D printer

- Open Source Arc Analyzer: Multi-Sensor Monitoring of Wire Arc Additive Manufacturing

- Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- Slicer and process improvements for open-source GMAW-based metal 3-D printing

- MOST open-source metal 3-D printer v2

- Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing - how to get your print off the substrate with a hammer

- In Situ Formation of Substrate Release Mechanisms for Gas Metal Arc Weld Metal 3-D Printing

- Particle Swarm Optimization of Printing Parameters for Open-Source TIG-Based Metal 3D Printing

- Open-source Lab

- Open source 3-D printing of OSAT

- Applications of Open Source 3-D Printing on Small Farms

- Building research equipment with free, open-source hardware

- Delft University of Technology - MIG+ Prusa I3

- Weld 3D - 1st commercial spin off

- Open Source 3D-Printable Planetary Roller Screw for Food Processing Applications

- see literature on "wire arc additive manufacturing" (WAAM)

Media[edit | edit source]

- Open Source Advocate Dr. Joshua Pearce Publishes Paper on Inexpensive GMAW Metal 3D Printing 3D Print, Bad Blue Tech

- Michigan Tech engineers develop open-source GMAW metal 3D printer for only $1,200 3Ders, Tux Machines, FutureLab 3D

- La stampante 3D in metallo GMAW tecnologia di stampa 3D in metallo a basso costo e open source Stampare in 3D

- 密歇根工程师开发只需1200美元的开源GMAW金属3D打印机 3D Day In

- 工程师开发出只需1200美元的开源GMAW金属3D打印机 3D Hoo

- 工程师开发出只需1200美元的开源GMAW金属3D打印机 3D Print of the Week (9,830)

- 工程师开发出只需1200美元的开源GMAW金属3D打印机 KD Youth (97)

- 仅需1200美元!工程师开发开源GMAW金属3D打印机 Xincailiao

- 仅需1200美元!工程师开发开源GMAW金属3D打印机 Today Chemical

- 工程师开发开源GMAW金属3D打印机,仅需1200美元 Maker8

- 美国新的开源金属3D打印机,成本低至1200美元 3D Printing World

- 工程師開發出只需1200美元的開源GMAW金屬3D印表機 Read 01 (3,313)

- 開源金屬3D印表機只需1200美元,密西根理工學院的工程師開發 KK News (1,396)

- 工程师开发出只需1200美元的开源GMAW金属3D打印机 ITMSC

- Джошуа Пирс опубликовал проект недорогого 3D-принтера для печати металлами 3D Today (26,642)

- Can You 3D Print an Axe? - Hack A Day (9173)