The goal of this project was to reduce the amount of unique connecting pieces needed to construct World Shelter's Just Add Sticks (JAS) shelter. The Simple Square successfully reduced the four pieces that were needed into one connecting piece. None of the angles were altered so structural stresses remain the same.

Introduction[edit | edit source]

Team ACE is part of Cal Poly Humboldt's spring 2010 Engineering 215 Intro to Design. Team ACE is composed of Chad Herrick, Adam McGuire, and Enrique Diaz. Team ACE worked with World Shelters on improving the design of the Just Add Sticks Shelter. World Shelters is a non profit organization that constructs shelters for domestic and international natural disaster victims.

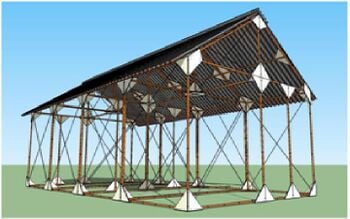

The Just Add Sticks or JAS shelter is a low cost transitional shelter for natural disaster survivors[1]. The JAS shelter is constructed with available dimension cut "sticks" which are then tied together with corrugated polypropylene connections and zip-ties to form the basic structure. In the case of the Haiti relief effort the "sticks" being used in construction are harvested bamboo originating from South America[1]. The JAS shelter is a modular design, and sections can be added in repeating units to accommodate larger numbers of people. Enclosing an 18m2 area, a single JAS shelter can provide protection from the elements for five people[1].

Problem Statement and Criteria[edit | edit source]

The objective of Team ACE is to reduce shipping and manufacturing costs of by reducing the number of unique connecting pieces required to construct the JAS shelter.

-

Original Square Cross

-

Original Right Truss

-

Original Left Truss

-

Original Roof Peak

| Criteria | Description | Weight |

|---|---|---|

| Reduction of Unique Parts | Reduce the Number of Connecting Pieces | 10.0 |

| Equal or Improved Performance | The JAS shelter's ability to shelter inhabitants | 9.7 |

| Sensible Load Distribution | The stress placed on the joints | 9.3 |

| Cost | The amount of money needed to implement solution | 8.8 |

| Simplified Assembly | Time and skill needed by workers to construct JAS | 8.0 |

| Minimal Parts/ Materials | Amount of materials and tools needed to construct JAS | 7.5 |

Simple Square Solution[edit | edit source]

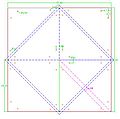

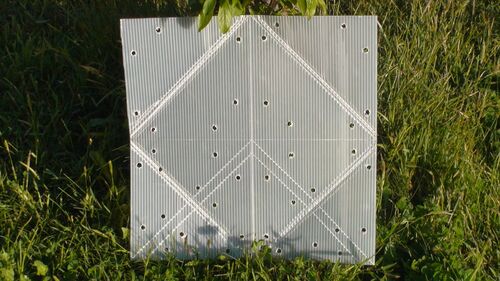

The Simple Square is a universal connector piece. Its design decreases the number of unique the connector pieces needed to reinforce the structural properties of the JAS structure. The Simple Square adapts World Shelter's Square Cross connector piece to create roof peak and truss eaves connector variations of the JAS structure. Measuring 50x50 cm with an area of 2500 cm2 the Simple Square utilizes 5 mm thick corrugated polypropylene sheets. Some minor modifications must be made to create unique pieces. All unique pieces (Left/Right Truss Eave, and Roof Peak) require a center-line cut for fabrication. If this center-line cut can be easily made with a utility knife as long as the cut is parallel to the corrugations. The left and Right Truss Eaves require an extra fold. Eight extra holes are needed for the Roof Peak. Because there is only two Roof Peaks and four Truss Eaves in the entire JAS shelter extra labor costs are minimal.

-

Simple Square Template

-

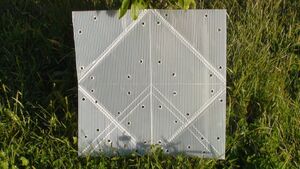

Simple Square

-

Roof Peak

-

Roof Peak

-

Truss Eave

-

Truss Eave

Costs[edit | edit source]

The Simple Square project cost $241.55 for all the necessary materials. World Shelters donated $101.13 in materials to Team Ace, so as a group Team Ace spent $140.42. Team ACE constructed a 1:3 scale model of the JAS Shelter to test connecting pieces, the 1:3 model used 1" by 2" Furring Strips in place of bamboo.

| Materials | Unit Cost ($per Unit) | Quantity | Retail cost ($) | Team cost ($) |

|---|---|---|---|---|

| 1"X2"X8' Furring Strips | Individual | 16 | 1.31 | 20.96 |

| Drywall screws, 2.5" | 1.49/lb | 1 | 1.49 | 1.49 |

| 4'x8' 6mm corrugated polypropylene | Individual | 1 | 22.00 | 22.00 |

| 4'x8' 4mm corrugated polypropylene | Individual | 1 | 23.00 | 23.00 |

| Magnifying glass | Individual | 1 | 4.99 | 4.99 |

| Bamboo full rounds-16' | Individual | 5 | 10.00 | 50.00 |

| Hole punch | Individual | 1 | 5.99 | 5.99 |

| Self-Tapping screws & washers | 2.89/lb | 2 | 5.78 | Donated |

| 5mm corrugated polypropylene | 1.55/ft2 | 100 | 155.00 | Donated |

| Zip-Ties (100 qty) | 11.99/package | 1 | 11.99 | 11.99 |

| 241.55 | 140.42 |

Maintenance Costs[edit | edit source]

Maintenance costs of the Simple Square are based upon the JAS shelter's "six-month" emergency/ transitional shelter timeframe and remains the same as original maintenance costs. Zip-ties, securing the connection pieces and frame sticks, need to be securely fastened and tightened or replaced whenever they are found to be lose or missing. If proper care is taken during initial construction, zip-ties should not require tightening or replacement within the designed time frame of six months.

Labor[edit | edit source]

Testing Results[edit | edit source]

Team ACE constructed one modular section of the JAS shelters to test the strength of the Simple Square design. Weights were placed at the corners of the modular section. In all tests the bamboo fractured before the polypropylene corner pieces.

Discussion and Next Steps[edit | edit source]

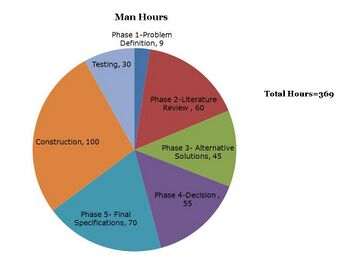

After 369 hours of work with the JAS shelter Team ACE has several recommendations to improve the JAS shelter design. Team ACE recommends the use of smaller diameter, whole bamboo timbers, instead of large split timbers. Bamboo is much stronger in its natural cylindrical form than when split into pieces. World Shelters could also save money by implementing the Simple Square solution. A universal connecting piece means less manufacturing and shipping costs. Proper testing on the simple square connecting pieces with World Shelter's bamboo timbers will need to be done to ensure safety to the inhabitants.

References[edit | edit source]

- ↑ 1.0 1.1 1.2 World Shelters, 2009. "Involvement." < http://worldshelters.org/involvement> (Feb. 27, 2009)